3D Printing Filament Guide for Beginners

Selecting the right 3d filament types is important for your project. Hopefully this 3D printing filament guide can eliminate the guess-work for the beginners.

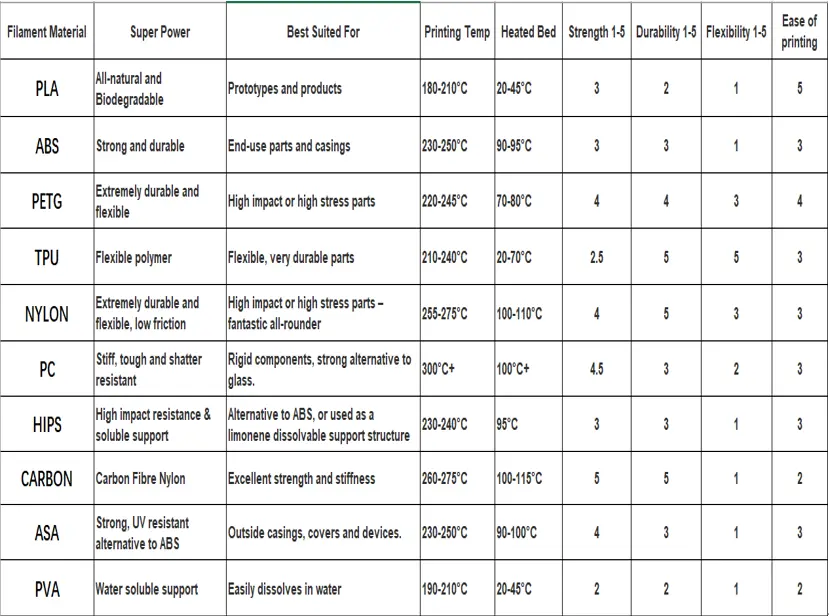

The chart below will give you a general understanding of the basic filament.

WHAT IS PLA?

In the realm of consumer 3D printing, polylactic acid (PLA) is king. PLA filament is an eco-friendly biodegradable material made from cornstarch.

PLA is easy to print with. It has a lower printing temperature than ABS, and it doesn’t warp as easily. You’ll find PLA is also non-toxic and doesn’t smell much when printing.

Another appealing aspect of PLA is that it’s available in a nearly endless abundance of colors and styles. Many of these specialty filaments use PLA as the base material, such as those with conductive or glow-in-the-dark properties, or those infused with wood or metal.

WHEN SHOULD I USE PLA 3D PRINTER FILAMENT?

In this case, the better question might be, When shouldn’t I use PLA? Compared to other types of 3D printer filament, PLA is brittle, so avoid using it when making items that might be bent, twisted, or dropped repeatedly, such as phone cases, high-wear toys, or tool handles.

You should also avoid using it with items that need to withstand higher temperatures, as PLA tends to deform around temperatures of 60°C or higher. For all other applications, PLA makes for a good overall choice in 3D printer filament.

Common prints include models, low-wear toys, prototype parts, and containers.

WHAT IS ABS?

Acrylonitrile butadiene styrene (ABS) typically ranks as the second most popular 3D printer filament, after PLA. But that just means it’s the second most commonly used. With respect to its material properties, ABS is actually moderately superior to PLA, despite being slightly more difficult to print with. It’s for this reason that ABS is found in many manufactured household and consumer goods, including LEGO bricks and bicycle helmets!

Products made of ABS boast high durability and a capacity to withstand high temperatures, but 3D printer enthusiasts should be mindful of the filament’s high printing temperature, tendency to warp during cooling, and intense, potentially hazardous fumes. Be sure to print with a heated bed and in a well-ventilated space (or with an enclosure).

WHEN SHOULD I USE ABS 3D PRINTER FILAMENT?

ABS is tough – able to withstand high stress and temperature. It’s also moderately flexible. Together these properties make ABS a good general-purpose 3D printer filament, but where it really shines is with items that are frequently handled, dropped, or heated. Examples include phone cases, high-wear toys, tool handles, automotive trim components, and electrical enclosures.

WHAT IS PETG?

Polyethylene terephthalate (PET) is the most commonly used plastic in the world. Best known as the polymer used in water bottles, it is also found in clothing fibers and food containers. While “raw” PET is rarely used in 3D printing, its variant PETG is an increasingly popular 3D printer filament.

The ‘G’ in PETG stands for “glycol-modified”, and the result is a filament that is clearer, less brittle, and most importantly, easier to print with than its base form. For this reason, PETG is often considered a good middle ground between ABS and PLA, the two most commonly used types of 3D printer filament, as it is more flexible and durable than PLA and easier to print than ABS.

Three things 3D printer enthusiasts should keep in mind when using PETG:

PETG is hygroscopic, meaning it absorbs moisture from the air. As this has a negative effect on the material, make sure to store the 3D printer filament in a cool, dry place.

PETG is sticky when it’s being printed, making this 3D printer filament a poor choice for support structures, but good for layer adhesion. (Just be careful with the print bed!)

Though not brittle, PETG scratches more easily than ABS.

WHEN SHOULD I USE PETG (PET, PETT) 3D PRINTER FILAMENT?

PETG is a good all-rounder but stands out from many other types of 3D printer filament due to its flexibility, strength, and resistance to both high temperature and impact. This makes it an ideal 3D printer filament to use for functional objects which might experience sustained or sudden stress, such as mechanical parts, printer parts, and protective components.

WHAT IS TPU?

Thermoplastic polyurethane (TPU) is a particular variety of TPE, and is itself a popular 3D printer filament. Compared to generic TPE, TPU is slightly more rigid – making it easier to print. It’s also a little more durable and can better retain its elasticity in the cold.

WHEN SHOULD I USE TPE, TPU, OR TPC 3D PRINTER FILAMENT?

Use TPU when creating objects that need to take a lot of wear. If your 3D printed part will bend, stretch, or compress, these 3D printer filaments should be up for the task. Example prints might include toys, phone cases, or wearables (like wristbands).

WHAT IS NYLON?

Nylon, a popular family of synthetic polymers used in many industrial applications, is the heavyweight champion of the professional 3D printing world. Compared to most other types of 3D printer filament, it ranks as the number one contender when together considering strength, flexibility, and durability.

Another unique characteristic of this 3D printer filament is that you can dye it, either before or after the printing process. The negative side to this is that nylon, like PETG, is hygroscopic, meaning it absorbs moisture, so remember to store it in a cool, dry place to keep the filament in prime condition, ensuring better quality prints.

WHEN SHOULD I USE NYLON 3D PRINTER FILAMENT?

Taking advantage of nylon’s strength, flexibility, and durability, this type of 3D printer filament can be used to create tools, functional prototypes, or mechanical parts (like hinges, buckles, or gears).

WHAT IS PC?

Polycarbonate (PC), in addition to being one of the strongest 3D printer filament presented in this list, is extremely durable and resistant to both physical impact and heat, able to withstand temperatures of up to 110°C. It’s also transparent, which explains its use in commercial items such as bulletproof glass, scuba masks, and electronic display screens.

Despite being featured in similar use cases, PC shouldn’t be confused with acrylic or plexiglass, which tend to shatter or crack under stress. Unlike these two materials, PC is moderately flexible (though not as much as nylon, for example), allowing it to bend until it eventually deforms.

PC 3D printer filament is hygroscopic, able to absorb water from the air, so remember to store it in a cool, dry place to ensure better quality prints.

WHEN SHOULD I USE PC 3D PRINTER FILAMENT?

Due to its physical properties, PC is an ideal 3D printer filament for parts that need to retain their strength, toughness, and shape in high-temperature environments, such as electrical, mechanical, or automotive components. You can also leverage its optical clarity for lighting projects, screens, and other applications that call for transparency.

WHAT IS HIPS FILAMENT?

In the commercial world, high impact polystyrene (HIPS) – a copolymer that combines the hardness of polystyrene and the elasticity of rubber – is commonly found in protective packaging and containers, like CD cases.

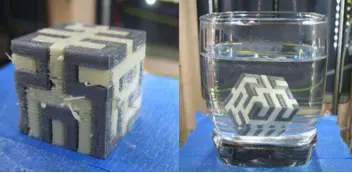

In the world of 3D printing, HIPS typically plays a different role. 3D printers can’t print onto thin air – that’s where support structures come in. Overhangs require some underlying structure, and this is where HIPS really shines. When paired with ABS in a dual extrusion printer, HIPS acts as an excellent support material.

For dual extrusion printing with HIPS, simply crank the supports to the max and fill any gaps in your design with HIPS 3D printer filament. Immersing the finished print in limonene will strip away the HIPS leaving your final product behind.

Unfortunately to use HIPS as a support material limits you to printing your actual part from ABS. Other 3D printer filament materials will be damaged by the limonene. Handily, HIPS and ABS print well together in any case, being of similar strength, stiffness, and requiring a comparable print temperature.

In fact, despite its primary use as a support material, HIPS is a decent 3D printer filament in its own right. It is stronger than both PLA and ABS, warps less than ABS, and can easily be glued, sanded, and painted.

WHEN SHOULD I USE HIPS 3D PRINTER FILAMENT?

Sharing many characteristics with ABS, HIPS 3D printing filament is a good all-rounder for parts that need to stand up to wear and tear or for projects that require a finishing-friendly material to achieve the end look.

WHAT IS CARBON FIBER FILAMENT?

When types of 3D printer filament like PLA, ABS, PETG, and nylon are reinforced with carbon fiber, the result is an extremely stiff and rigid material with relatively little weight. Such compounds shine in structural applications that must withstand a wide variety of end-use applications.

The trade-off is the increased wear and tear on your printer’s nozzle, especially if it’s made of a soft metal like brass. Even as little as 500 grams of this exotic 3D printer filament will noticeably increase the diameter of a brass nozzle, so unless you enjoy frequently replacing your nozzle, consider using one made of (or coated with) a harder material.

WHEN SHOULD I USE CARBON FIBER 3D PRINTER FILAMENT?

Thanks to its structural strength and low density, carbon fiber is a fantastic candidate for mechanical components. Looking to replace a part in your model car or plane? Give this 3D printer filament a try.

WHAT IS ASA FILAMENT?

Sure, ABS is great, but it has its flaws. That’s why plastics manufacturers are always looking for alternatives. One such alternative is acrylonitrile styrene acrylate (ASA), which was originally developed to be a hardy weather-resistant material. Hence it’s primary use in the automotive industry.

In addition to being a 3D printer filament that is strong, rigid, and relatively easy to print with, ASA is also extremely resistant to chemical exposure, heat, and most importantly, changes in shape and color. Prints made of ABS have a tendency to denature and yellow if left outdoors. Such is not the case with ASA.

Another minor benefit to using ASA over ABS is that it warps less during printing. But be careful with how you adjust your cooling fan; ASA can easily crack if things get a little too windy during printing.

WHEN SHOULD I USE ASA 3D PRINTER FILAMENT?

For anything from birdhouses to custom garden gnomes and replacement outlet covers, look no further than this 3D printer filament.

WHAT IS PVA?

Polyvinyl alcohol (PVA) is soluble in water, and that’s exactly what commercial applications take advantage of. Popular uses include packaging for dishwasher detergent “pods” or bags full of fishing bait. (Throw the bag in water and watch it dissolve, releasing the bait.)

The same principle applies in 3D printing, making PVA a great support material when paired with another 3D printer filament in a dual extrusion 3D printer. The advantage of using PVA over HIPS is that it can be used to support more materials than just ABS.

The trade-off is a 3D printer filament that is slightly more difficult to handle. One must also be careful when storing it, as the moisture in the atmosphere can damage the filament prior to printing. Dry boxes and silica pouches are a must if you plan to keep a spool of PVA usable in the long run.

WHEN SHOULD I USE PVA 3D PRINTER FILAMENT?

PVA filament is a great choice as a support material on complex prints with overhangs.