3D Printing in the Medical Industry

In the past, 3D printing was used mainly by major manufacturers that could afford expensive printers and materials. Over the years, 3D printing technology has evolved and become more affordable, making it a viable option for a wide variety of industries. Medical professionals, in particular, are beginning to use 3D printing to improve their practices and offer more customized and affordable healthcare options for their patients.

Healthcare is one industry in which 3D printing has made a lasting impact. In 2018, the medical 3D printing market was valued at USD973 million and is expected to grow to almost USD3.7 billion by 2026. Medical applications for 3D printing are vast and will likely change the industry forever. Here are some of the most significant applications of 3D printing in the medical field.

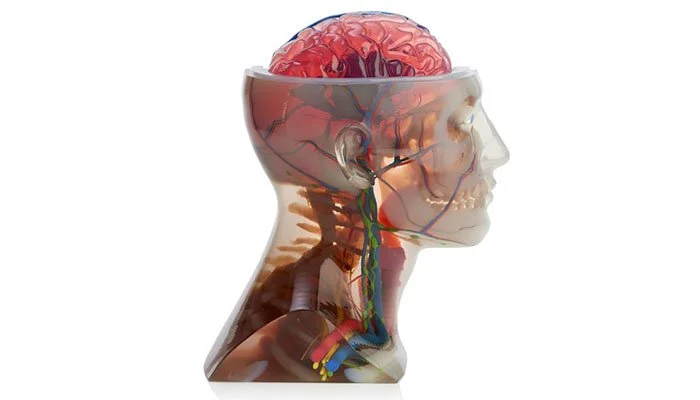

Models for surgical planning and education

While much of the focus for 3D printing in the medical industry has been around implants and medical devices used by patients, one of the largest areas of application has concentrated on anatomical replicas. Historically, clinical training, education, and device testing have relied on the use of animal models, human cadavers, and mannequins for hands-on experience in a clinical simulation. These options have several deficiencies including limited supply, expense of handling and storage, the lack of pathology within the models, inconsistencies with human anatomy, and the inability to accurately represent tissue characteristics of living humans.

Physicians are now using models produced by AM from patient scan data to improve the diagnosis of illnesses, elucidate treatment decisions, plan, and, in some cases, even practice selected surgical interventions in advance of the actual treatments. The models help physicians understand patient anatomy that is difficult to visualize, especially when using minimally invasive techniques. Models also assist in accurately sizing medical devices. Physicians can also use the models to explain an upcoming surgery to patients and their families and to communicate the surgical steps to the clinical team.

To help reduce cost some facilities have developed procedures where surgeons practice and plan operations on low cost mannequins that are transplanted with with patient-specific AM models. This coupled with the fact that AM technologies are able to produce both hard and soft materials in a single part, allowing the accurate replication of human tissue, calcification, and bone, means that surgeons can now obtain an even better understanding of exactly how a procedure needs to be performed right down to the touch and feel of the different parts of a patient’s anatomy.

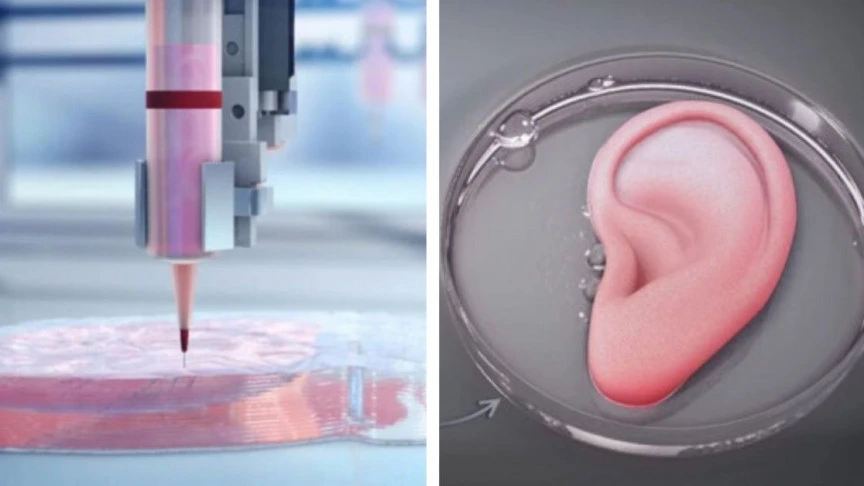

Creating tissues and organoids

Thanks to a process called bioprinting, medical 3D printers are now able to print functional tissue. Rather than using metal or plastic, bioprinters can create models with living cells. Soon, 3D printers in the medical field will be able to create tissue to help with skin grafting and reconstructive surgery. Labs are also starting to experiment with printing liver and intestinal tissue to help manage certain diseases.

In a more miraculous form of bioprinting, experts are using 3D printing to create functional human organs. So far, researchers have been able to replicate a working lung and an artificial heart. It won’t be long before patients won’t need to wait on transplant lists or spend inordinate amounts of money to get the organs they need.

Surgical instruments

Forceps, retractors, medical clamps, needle drivers, hemostats and scalpel handles are among the wide range of surgical tools that have been produced using 3D printing technology.

Because these tools are not as complex — or as invasive in their function — as human organs, additive manufacturing of surgical instruments is subject to significantly fewer regulatory hurdles and practical barriers, and as such has already been used far more widely in the healthcare sector.

The key benefit 3D printing holds in manufacturing these instruments is the fact that specific modifications can be made to designs, often based on feedback from surgeons after they have used a prototype.

The speed at which designs can be improved and printed also means alterations can be done rapidly — sometimes on the same day.

Implants

AM’s ability to produce fine mesh or lattice structures on the surface of surgical implants can promote better osseointegration and reduce rejection rates. Biocompatible materials such as titanium and cobalt– chrome alloys are available for applications in maxillofacial (jaw and face) surgery and orthopedics. The superior surface geometry produced by AM has been shown to improve implant survival rate by a factor of 2 when compared to traditional products. The porosity of these AM products coupled with the high level of customization and ability to manufacture them from traditional medical materials has resulted in AM implants becoming one of the fastest growing segments of the AM medical industry.

External prostheses

Prostheses made using traditional manufacturing methods are expensive and not necessarily adapted to a patient’s unique morphology. If a patient does need a custom prosthesis, the costs can skyrocket, and it would take some time for the order to be fulfilled.

Prostheses, by definition, need to be custom-made for the patient. After all, no two people are exactly alike or have the exact same injuries. Doctors can use 3D modeling software to help create detailed, three-dimensional images of prostheses that they can collaborate with each other – and perhaps more importantly, with the patient – to ensure a proper fit.

Then, using 3D printing, they can create customized prostheses that are perfectly suited to fit their patients’ exact needs in a timely, cost-effective manner.

With the incredible things happening with 3D printing in the medical industry, including detailed 3D models, customized tools, prosthetics, bone reconstruction, and synthetic organs, there’s no doubt that this is the future of healthcare.