Molding vs Injection Molding How to choose the right technology for your part?

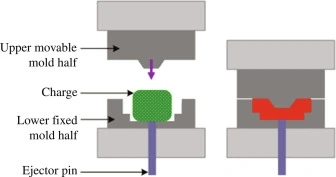

The step-by-step compression molding process works as follows:

STEP 1:Create molds

Tooling can be produced in a number of ways, including machining, die casting, 3D printing.

STEP 2:Set up the machine

Depending on the specific machine or device you’re using, this may include cleaning the mold, turning on the heat, and other set-up processes.

STEP 3:Prepare charge

Selected the type of material you want to use and determine the proper amount of material. If your charge is too big, excess material will seep out of the mold and result in flash that you will need to manually cut off.

STEP 4:Insert charge

Place the charge in the center of the bottom mold.

STEP 5:Compress part

Close the top mold, apply pressure, and wait for your piece to form. Many manufacturers also use heat during the compression process, which softens the raw materials and can help speed up production.

STEP 6:Release part

Remove the finished piece.

STEP 7:Clean part

Resin flash around the edges must be manually cut off or removed, and the part may need to be cleaned before the final assembly.

|

|