5 tips to reduce injection molding costs

While it is now regarded as a fairly cost-effective process, injection moulding is fundamentally a higher cost manufacturing route. However, the advantages that it offers in terms of precision, stability, fast throughput and repeatability make it desirable. If you are considering using it as a production method, but think that it doesn’t quite fit your manufacturing model, perhaps you should look at how it can be modified to reduce costs without skimping on all of the really desirable attributes.

The injection moulding process is actually a lot more flexible than you may think, and there are many elements of it which can be tweaked to reduce both the costs of the moulds and the products that they are used to make. With a little thought and some collaboration with your mould designer and manufacturer, you could soon see injection moulding as a viable process for even fairly low-number runs.

1.Optimized Plastic Parts Design

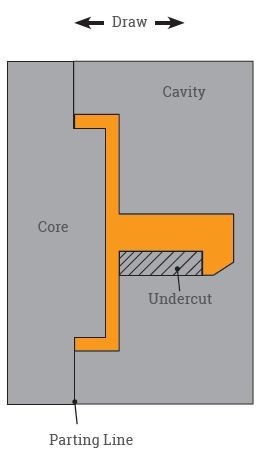

Complex part designs with intricate geometries require complex molds to execute the project. Mold designs usually have 2 sides: sides A and B. Side A, also known as the cosmetic side, is usually the side seen by the user. Side A is expected to be smooth and aesthetically pleasing. Side B contains the hidden structures that support the usage of the part. Side B structure may include ribs, bosses, etc., and its finish is usually much rougher than that of Side A. Molds with complex Side A and Side B designs are generally more expensive to fabricate compared to simpler molds. Complex designs that feature undercuts might also require sliding side-actions and cores, increasing the cost of the mold.

Eliminate undercuts

Undercuts require more complex tooling such as sliding cores. Eliminating undercuts can lower tooling costs and avoids additional time being spent working on the mould. For example, the clip feature on the left below is complex to injection mould due to the undercut present. By adding a slot underneath the clip feature, the undercut is removed and the part can be tooled far more easily.

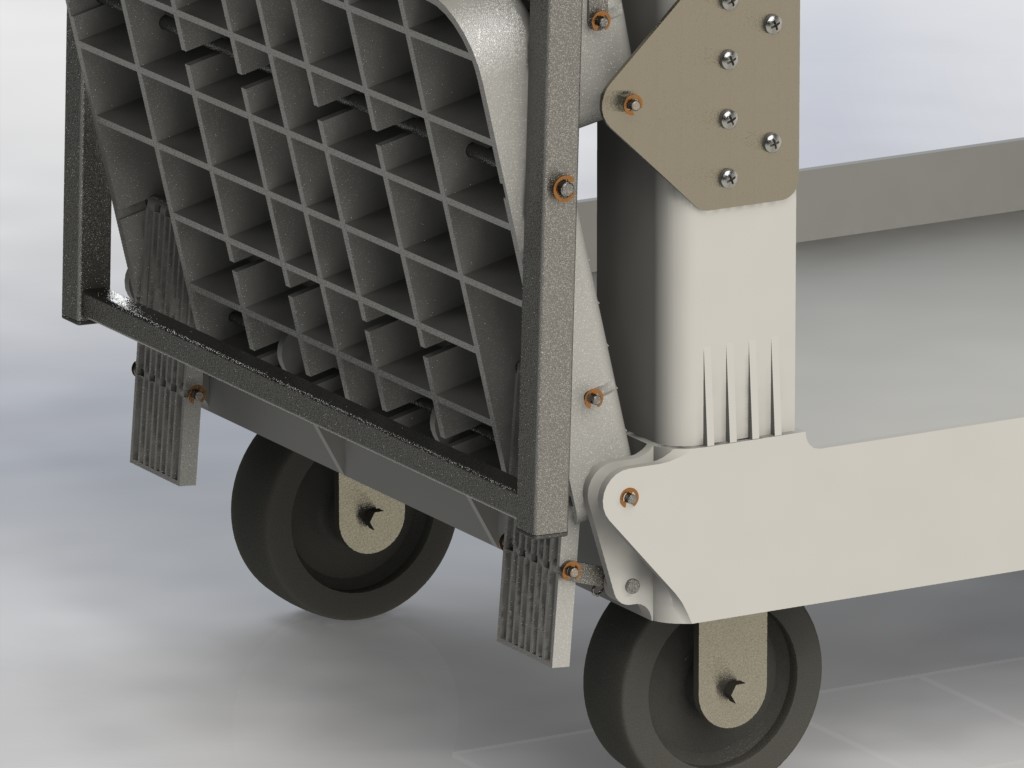

Ribs help minimizing the part volume

When an area of the part needs to be especially strong, but the wall is too thick, the solution is similarly simple: ribbing. Instead of making the entire part thick and difficult to cool, thin the exterior face into a shell, then add vertical ribs of material to the interior for strength and rigidity. In addition to easier molding, this reduces the amount of required material, reducing costs.

2.Don’t Use Unnecessary Cosmetics and Features

While you shouldn’t skimp on your features and cosmetics by any means, this doesn’t mean you should add every bell and whistle you can think of either. It’s nice to have a very aesthetically pleasing part, but the extra effort required in the mold you’ll be using can sometimes cut deeply into your profit margin.

For instance, if you want extra features on your part, you may need extra mold work to be done, such as EDM, bead blasting, or high mold polishing to achieve the specific cosmetic appearance you are seeking. This extra work can drastically impact cost reduction efforts.

At a smaller level, including company logos, textured surfaces, and molded part numbers are all features that, if deemed unnecessary, are penny pinchers that can help when pricing out injection molding costs

3. Material selection

Unless you’re designing a part for use in harsh environments such as extreme hot or cold, or for special-grade uses such as medical or food, material choice is often interchangeable. Rarely will you need to select a “Cadillac”-grade resin for a general-use part; and picking a lower cost material that can still suit your needs is an easy and effective way to lower your overall costs. A simple analysis of use cases for your product, along with quality requirements and your target market, can help you choose the right material for your price point.

4.Review your part tolerances.

Specifying overly tight tolerances will require additional mold manufacturing steps, increasing the mold manufacturing cost, production and molding cost, as well as residual maintenance cost. Ensure the tolerances you specify are truly necessary to meet your needs and identify where there’s room for flexibility. For some manufacturers, however, tight tolerances are justifiable to ensure part consistency over the long term. For example, Lego® building blocks have tolerances as small as 10 micrometers because they must engage with every other Lego block made over the last half-century, fitting firmly, yet allowing a child to disassemble them easily.

5. Family or Multi-Cavity Mold

Another way to reduce costs related to tooling is designing a family or multi-cavity mold. Depending on part similarity, material selection, and processing requirements you may be able to include more than one part in your mold. This will increase the cost of the tool but it will be marginal when compared to cutting separate tooling for each part.

Multi-cavity molding lends itself to high production requirements. The more cavities you have in a tool the more parts you’re able to create each cycle. While this will drive up initial costs related to tooling it will lead to lower part prices and lower cost overall in the long run.