Types of 3D Printing technologies in 2023

You might know 3D Printing is an additive manufacturing process in which parts are made layer by layer. It is still not easy to figure out the difference between different 3D Printing technologies as this technology changes every day, no worries. We are here to make it easy for you.

There are several types of 3D printing, which include:

- Stereolithography (SLA)

- Digital Light Process (DLP)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Multi Jet Fusion (MJF)

- PolyJet

- Selective Laser Melting ( SLM-Metal Printing)

So knowing the difference between each technology will help you select the best type of 3D printing technology, no matter whether you gonna choose a 3D Printing service or purchase your own 3D Printers.

Stereolithography (SLA)

SLA is the most popular 3D printing process for making plastic prototypes. SLA 3D Printers excel at producing parts with high details, smooth surface finishes, and tight tolerance. The print volume is from 2x2x2mm up to 1800mmx850x800mm which can make functional prototypes as fast as one day. The shortcoming of SLA is that most of the materials are not suitable for parts that need super-strength performance.

Digital Light Process (DLP)

DLP process is quite similar to SLA. When shall you choose DLP? We would like to say Parts need High details, and due to some DLP materials being compatible with skin and food, so select DLP for dental printing is a good choice.

Selective Laser Sintering (SLS)

SLS is a good choice if you need your parts to have high strength, pressure resistance, heat resistance, and be durable and as close as injection molded or machined parts. Because the laser will sinter/melt the nylon-based powder, resulting in a good performance. SLS process also has FREE printing support. Adding support is always a headache for most of the printing process. The shortcoming is SLS has a rough surface finish. But, thanks to vapor chemical smoothing, it will no longer be a problem.

If your projects have less care about the smoothness and tolerance, choosing desktop 3d printing is a good choice. You can buy a desktop FDM 3D printer with only 200usd or less. Many small 3D Printing service companies accept this kind of printer to offer their customers 3D Prints. Then you have to choose industrial FDM 3D printers to make parts that need tight tolerance and more smoothness. And another advantage of FDM is that it has more than 30 kinds of materials and 70+colors available. From PLA to PEEK.

Multi Jet Fusion (MJF)

Similar to SLS, MJF also produces nylon-based parts. As MJF is new compared with SLS, the currently available MJF nylons are nylon12, nylon11, and nylon12+GF, which have fewer materials than SLS. The SLS can produce more materials: Nylon6, Nylon6+Glass fiber, Nylon11+Glass fiber. Though MJF is young, it is one of the most widely used materials due to its high strength and repeatability. The shortcoming is its limited colors and rough surface compared with SLA. Sometimes, many users are confused about the selection of SLS and MJF. We want to say, SLS is more cost-effective. That’s it.

PolyJet

Polyjet 3D printing is mainly for multiple colors and multiple materials. Multiple colors are very easy to understand, polyjet offers no limitation on your colorful parts. So many artists and medical industry engineers choose it. But what are multiple materials? It will be easy if you know about over-molding, in which you can bond soft and rigid materials together.

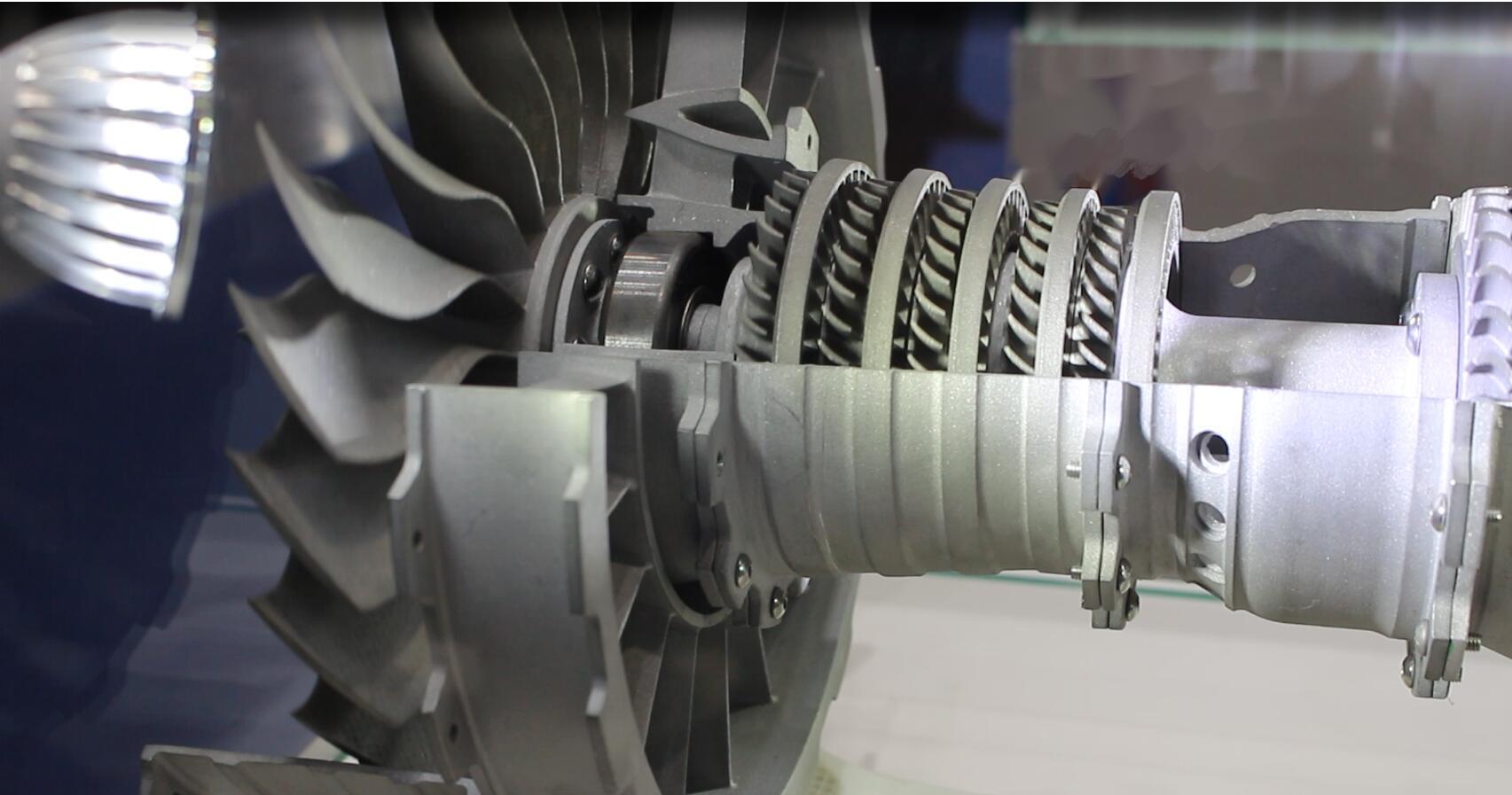

Selective Laser Melting( SLM-metal)

The Metallic 3D Printing cost from IN3DTEC is very competitive. The laser can melt the metal powders so that this technology can produce super-strong and functional metal parts, especially after the details with heat-treatment. Today, there are many metals 3d printing materials such as AlSi10Mg (Aluminum), Stainless 316, Maraging Steel, Titanium, Copper, and Nickel Alloy.

In addition to the above technologies, there are many other types of 3D printing technologies, such as DMLS, MBJ, EBM… We will talk about this in the following articles.