What are 4-axis and 5-axis CNC Machining?

Milling and turning are crucial phenomena in the manufacturing of several mechanical parts for various industries like aerospace engineering, medical sciences, and automobiles.

However, the formation of respective complex geometries of components necessitates a variety of tool movements. It happens because the work piece is usually stationary while the cutting tool rotates and reciprocates to form complex shapes.

Not only do the benefits listed above apply, but the motion of a cutting tool has additional advantages for manufacturers, such as accuracy, precision, and customized structures. It is why, on the basis of an axis, three types of CNC machining.

- 3-Axis CNC Machining

- 4-Axis CNC Machining

- 5-Axis CNC Machining

The article covers all stories about all CNC machining types, why the latter two are more popular than the former, and their differences.

3- Axis CNC Machining

3-Axis CNC machining works on three coordinate systems: X, Y, and Z. It implies that its spindle and cutter move only three axes, not others. It is a good option for limited geometries, not for complex ones.

Limitations of 3-Axis CNC Machining Make it Unpopular

As it sounds, the perfect machine only has three axes, so it does not access hard-to-reach sections of the work piece. Such a severe limitation encourages manufacturers to carry out multiple rotations of a single fixture, which reduces productivity.

Seeing the above failures of 3-axis CNC machining, innovators have innovated its further developments in the form of 4-axis and 5-axis machining.

What about 4-Axis CNC Machining?

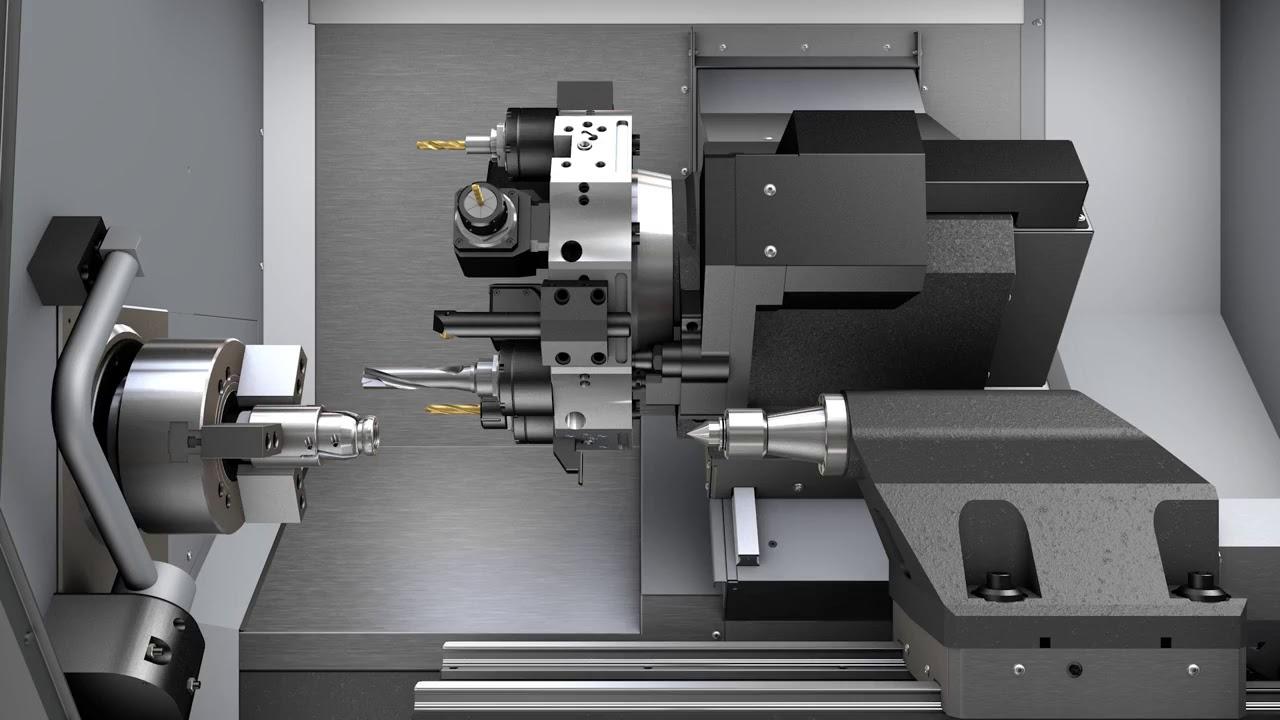

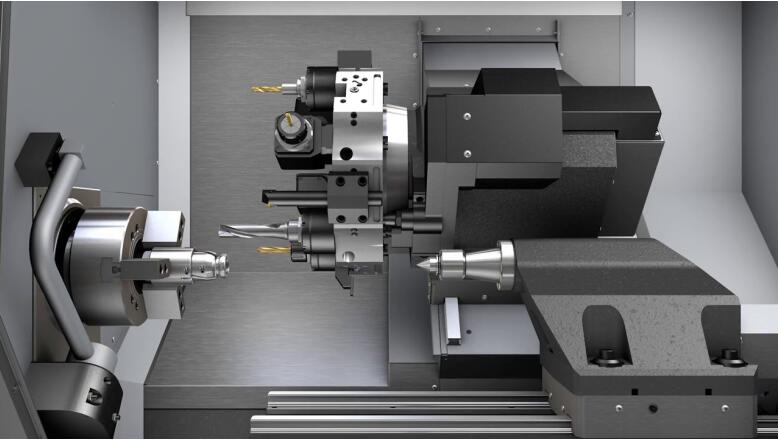

4-Axis CNC machining adds more functionality because it has one more additional rotational axis to work on a work piece. It has a spindle and a cutter that travel up and down, side to side, back and forth, and rotary along the X-axis. It brings more facilities, including high accuracy and speeding up the production process.

What exactly is 5-Axis CNC Machining?

5-Axis CNC machining has one more extra edge over its 4-axis counterpart. It provides for working on the work piece in total on five axes: up and down, side to side, forth and back, and rotation on two axes from three: the x-axis, y-axis, and z-axis.

5-Axis CNC is very efficient in performing milling, turning, tapering, and grooving on various parts using a single fixture.

Distinctions Between 4-Axis and 5-Axis CNC Machining

There is no major difference between 4-axis and 5-axis CNC machining, but if we look in-depth, we will find some subtle contrasting factors. Let us explore each one in a concise way.

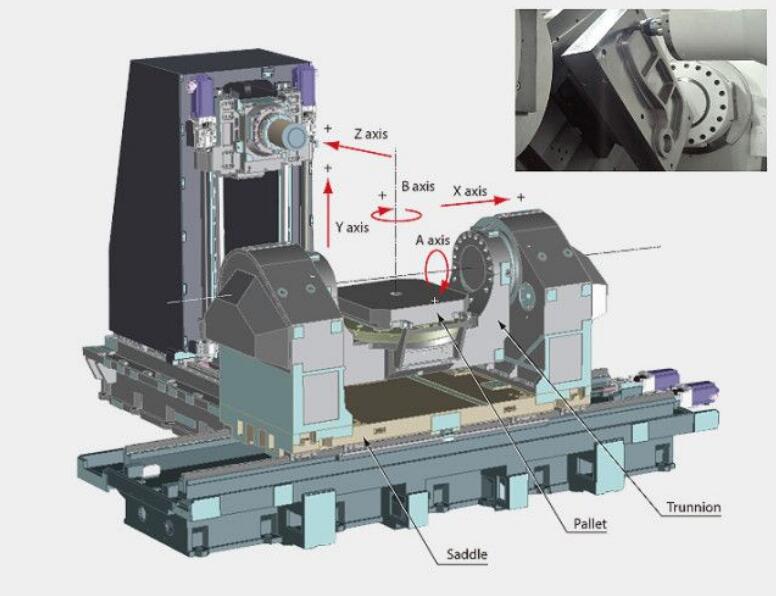

Contrasting in their Axes

4-axis CNC machining functions on three coordinate systems and rotation on the x-axis. 5-axis CNCs, on the other hand, operate on the x, y, and z axes as well as two additional rotational axes in addition to the three x, y, and z axes.

Versatility

5-axis CNC machining does not function in a localized way unlike to 4-axis one. It rotates along two of the three axes, x, y, and z. This means that 5-axis machining allows you to rotate a cutter in any of the two axes of your choice, whereas 4-axis machining only allows for x-axis cutter rotation.

Benefits of 4-Axis and 5-Axis CNC Machining

4-axis CNC machining is the updated version of 3-axis CNC machining. The former has more precision, accuracy, and efficacy than the latter. And if you prefer 5-axis CNC machining, it provides a more free hand in turning and milling operations.

5-axis CNC machining has added one exceeding advantage for the facilitation of manufacturers. It lets them perform machining operations in any direction and on any side of the work piece without using multiple spindles to rotate its movement.