Surface finishes options for metal 3D Prints

Metal 3D printing has completely revolutionized the manufacturing industry by enabling the rapid and cost-effective production of complex metal parts.

However, the inherent nature of the metal 3D printing process often results in surfaces that may require additional treatment to achieve the desired aesthetics, functionality, and performance. This is where surface finishing becomes crucial.

In this article, we will explore various surface finishes specifically tailored for metal 3D prints. These techniques not only improve the appearance but also enhance the mechanical performance, surface quality, and suitability for specific applications.

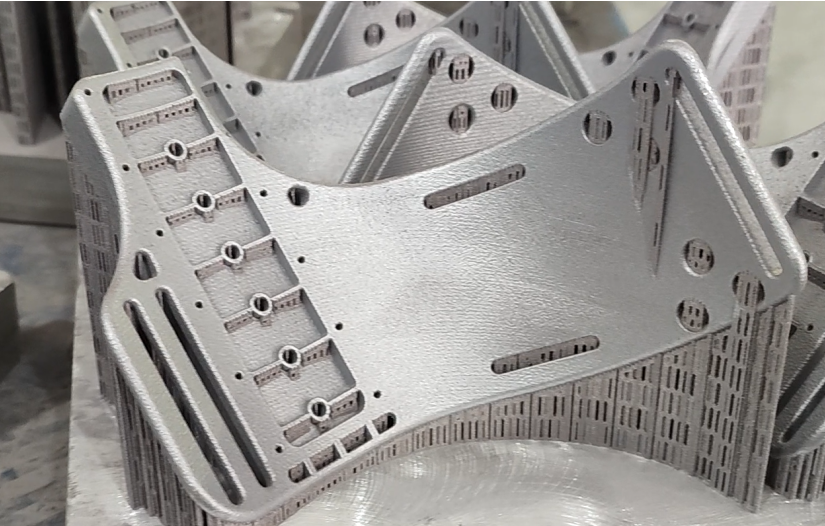

As-Printed Finish:

This type of surface typically has visible layer lines and some traces resulting from the removal of supports. The roughness is RA7. However, even without surface treatment, it does not affect the accuracy of the part. This surface finish is also a good choice for parts that require secondary processing.

Machined Finish:

For parts that require high precision, secondary machining is necessary. The highest achievable precision is +/- 0.02mm. For parts that require this type of post-processing, it is essential to leave enough cutting allowance before printing. After the post-processing, the printed parts can achieve the normal precision and surface smoothness of CNC machining. It also opens up possibilities for other additional post-processing techniques.

Media Blasting surface finishes:

Media blasting used in metal 3d printing, is a highly effective method that utilizes compressed air to propel blast media, such as alumina, stainless steel shot, metal powder, or glass beads, onto a part’s surface. This process helps wear down the surface and achieve a uniform matte or shiny finish.

It is particularly advantageous for tasks like removing discoloration, blending surface scratches, and mitigating tool marks. Importantly, media blasting does not compromise the dimensional accuracy of parts and can be completed in just a matter of minutes.

The media blasting process’s aggressiveness can be tailored by adjusting the air pressure. Lower pressures are suitable for altering the surface color of a part, while higher pressures with steel shot or glass beads can effectively deburr the surface, enhancing its smoothness and overall appearance.

Glass bead blasted surface. It results in a satin and uniform finish.

Glass bead blasted surface. It results in a satin and uniform finish.

Chemical Surface Treatment:

Chemical treatments such as etching or passivation can be used to alter the surface finish of metal 3D printed parts. These treatments can remove impurities, improve corrosion resistance, or create specific textured patterns on the surface.

However, before carrying out such surface treatments, it is necessary to polish and sand the surface of the samples to increase their durability.

Electropolishing

Electropolishing is an ideal solution for polishing irregularly-shaped objects, the process reduces surface roughness, levels micro-peaks and valleys and dramatically improves surface finish.

Electroplating is a process in which an electric current is employed to attract positively-charged metal ions, dissolved in a solution, towards a negatively-charged part. This results in the formation of a thin metal coating that covers the entire surface of the part.

Allegheny Image Source

Anodizing, painting:

Similar to CNC machining, these processes are also applicable to metal printed parts. However, compared to CNC machining, the surface finish of metal printed parts is generally poorer. If direct oxidation or painting processes are applied, the color of the finished parts may appear inconsistent, and visible lines or pits may be present. Therefore, some post-processing is required before performing such treatments.

For parts with less demanding surface requirements, bead blasting and tumbling can be performed on the samples. For parts with higher surface quality requirements, fine polishing and polishing treatments can be carried out.

Tumbling:

This process is very similar to traditional polishing techniques used in jade and jewelry making. The equipment principles and materials used are nearly identical. When determining whether a sample requires tumbling, the most important factor is to observe if there are delicate details on the surface that could be easily damaged, such as threads or thin-walled structures. In such cases, caution should be exercised when using this process.

The main material used in tumbling is small stones with triangular edges, along with some incremental additives. After undergoing tumbling, the surface of the samples appears shiny and polished.

Manual polishing:

Due to its flexible and simple operation, as well as low equipment requirements, it is the most traditional but also the most effective and widely used polishing method. Commonly used metal polishing tools include metal polishing buffing wheels, grinding stones, sanding bands polishers, rotary polishers, rotating belt wheels, and so on. It is necessary to pay attention to the intensity of polishing to avoid compromising precision and surface effects.

It’s important to note that the specific surface finishes achievable with metal 3D printing may vary depending on the printing technology used (e.g., selective laser melting, electron beam melting, binder jetting) and the type of metal being printed. Additionally, post-processing techniques can be combined or customized to achieve specific surface requirements based on the desired application or aesthetics of the part.