Exploring the Fascinating World of Metal 3D Printing: Types and Processes

Metal 3D printing has revolutionized the manufacturing industry, enabling the creation of complex and intricate metal parts with unparalleled precision. This groundbreaking technology has made significant advancements in recent years, offering a range of metal 3D printing techniques that cater to various applications. In this blog post, we will delve into the different types of metal 3D printing and explore how each process works.

Technology | Build Size mm | Supported Material | Tolerance | Production Cost | Roughness |

PBF(SLM) | 500x500x500 | Copper, 316Lsteel, AL, Ti, Maraging steel, 17-4PH, Inconel, Copper | +/-0.2mm | $$ | Ra7 |

Directed Energy Deposition (DED) | 600x450x500 | titanium and its alloys, inconel, tantalum, tungsten, niobium, stainless steel, aluminum, nickel, cobalt, tin, copper | +/-0.5 or higher | $$ | Very rough |

Binder Jetting | 490x380x260 | Silver,metals, ceramics, stainless steel, bronze, aluminum, titanium, zirconia | +/-0.2mm or higher | $$$$ | Ra15 |

Metal Extrusion | 200x200x200 | Aluminum, 316L stainless steel | +/-0.3mm or higher | $ | Ra14-Ra25 |

Remark: The printing size is determined by the stable and well-established printing capabilities that most manufacturers can achieve in 2023. However, it should be noted that this size does not necessarily reflect the maximum potential of the technology to produce larger prints. The cost takes into account all the expenses associated with post-processing and secondary manufacturing processes.

Tolerance: Based on length less than 100mm

Related article: Directed energy deposition investigation

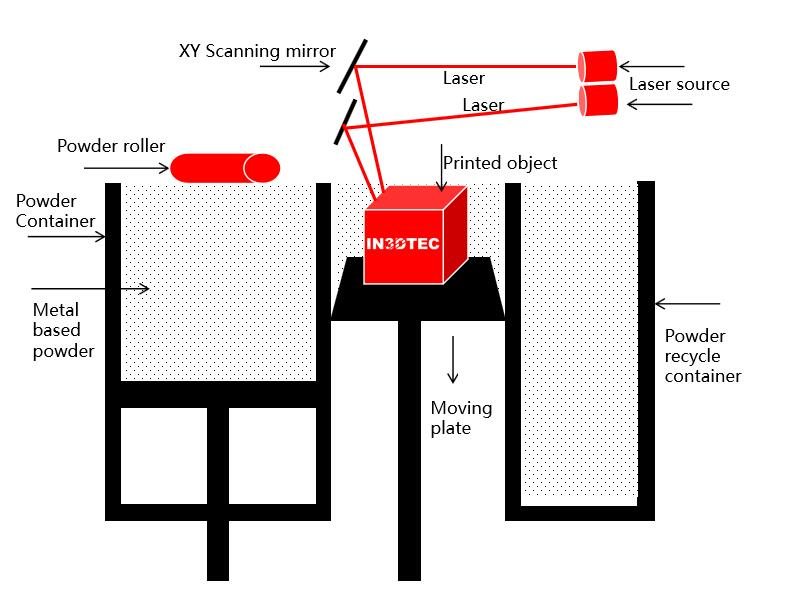

1. Powder Bed Fusion (Selective Laser Melting):

Powder Bed Fusion (PBF), also known as Selective Laser Melting (SLM) or Direct Metal Laser Sintering(DMLS), is one of the most widely used methods for metal 3D printing. The process begins with a thin layer of metal powder being spread across a build platform. A high-powered laser then selectively fuses the powder particles together, layer by layer, based on the 3D model’s specifications. As each layer solidifies, the build platform lowers, and a fresh layer of powder is spread on top. This process repeats until the entire part is printed. PBF/SLM offers excellent resolution, intricate geometries, and the ability to print a wide range of metals, including titanium, aluminum, stainless steel, and more.

Advantages: Excellent precision and detail, high density of printed parts, good mechanical properties.

Disadvantages: Limited build size, potentially high equipment and material costs.

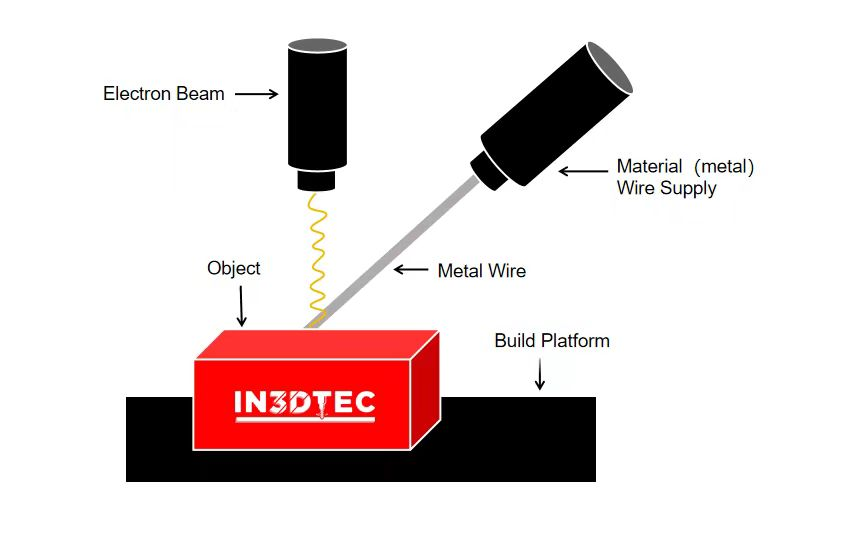

2. Directed Energy Deposition (DED):

Directed Energy Deposition (DED) is a metal 3D printing technique that involves the use of a nozzle or similar apparatus to deposit molten metal onto a substrate. The metal feedstock, in the form of a wire or powder, is guided by the nozzle and melted using a laser, electron beam, or plasma arc. This molten material is then precisely deposited layer by layer to build the desired metal part. DED is known for its high deposition rates, making it suitable for large-scale manufacturing, repair, and modification of existing components. It is commonly used with metals such as titanium, steel, and nickel alloys.

Advantages: Fast printing speed, ability to print large-scale parts, good material deposition rates.

Disadvantages: Lower precision compared to other methods, limited detail resolution, higher porosity in printed parts.

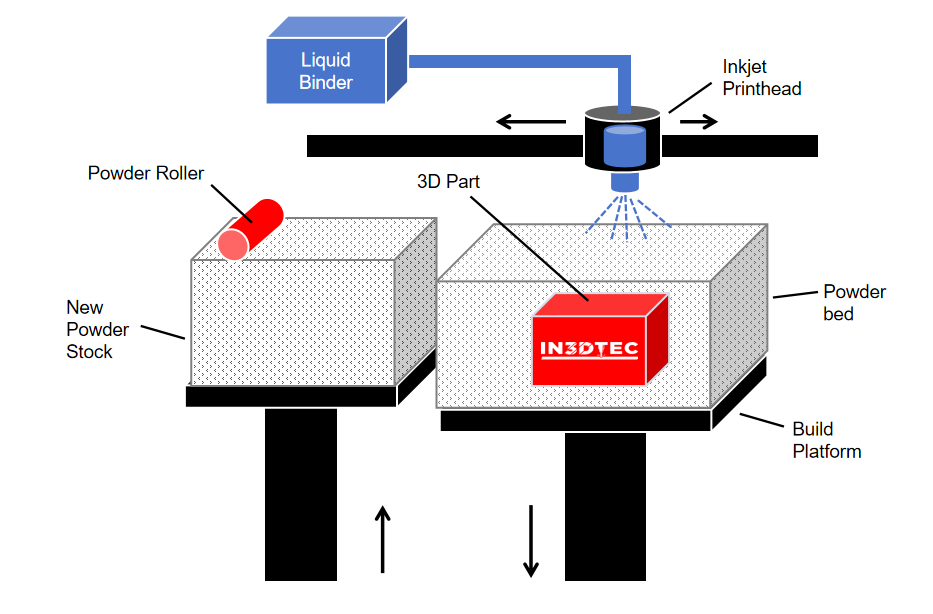

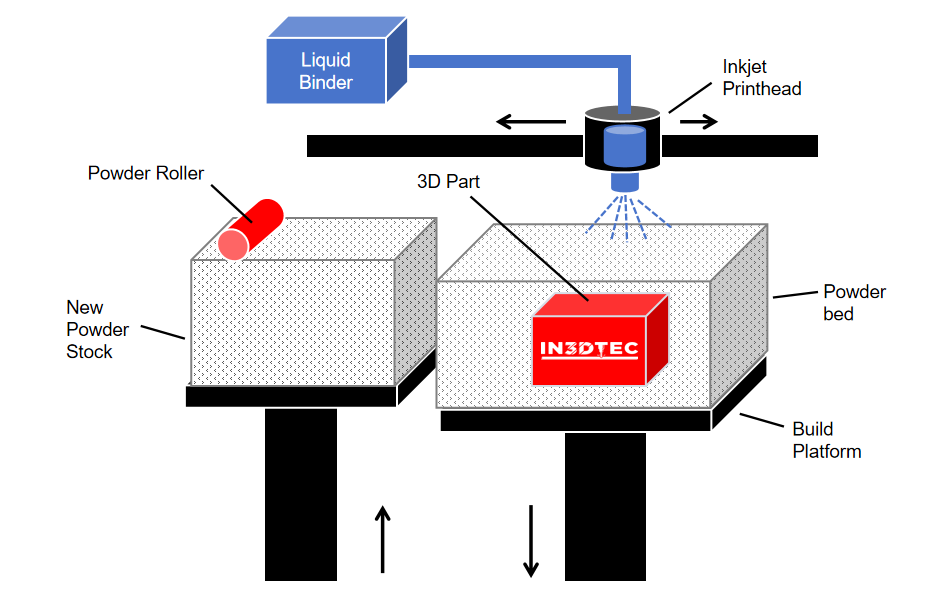

3. Binder Jetting:

Binder Jetting is a metal 3D printing technique that utilizes a powdered metal material and a liquid binder. The process starts by selectively depositing a liquid binder onto a thin layer of metal powder. The binder acts as an adhesive, binding the metal particles together. This process is repeated layer by layer until the entire part is formed. After the printing is complete, the part is typically subjected to a debinding process to remove excess binder, followed by a sintering process to fuse the metal particles together. Binder Jetting is known for its speed, cost-effectiveness, and the ability to print a wide range of metal alloys.

Advantages: Fast printing speed, suitability for a wide range of materials, lower equipment costs compared to other methods.

Disadvantages: Lower part strength compared to some other methods, limited detail resolution, post-processing requirements for sintering/binding.

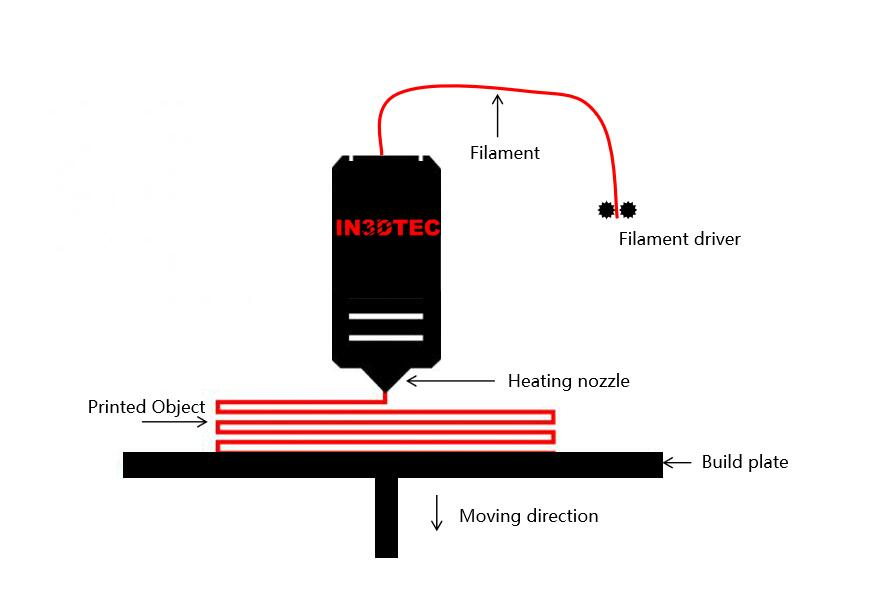

4. Metal Extrusion:

Metal Extrusion, also known as Material Extrusion or Fused Filament Fabrication (FFF), is a metal 3D printing process that is similar to the widely known plastic 3D printing method, fused deposition modeling (FDM). In this technique, a metal filament or metal-filled polymer filament is heated and extruded through a nozzle. The melted material is then precisely deposited layer by layer to create the final metal part. While Metal Extrusion is not as common as the other methods for metal 3D printing, it offers advantages such as affordability, ease of use, and the ability to print with different metal materials such as copper, bronze, and stainless steel.

Advantages: Fast printing speed, lower equipment costs compared to other methods.

Disadvantages: Lower part strength compared to some other methods, limited detail resolution, post-processing requirements for sintering/binding.

Conclusion:

Metal 3D printing has opened up a world of possibilities in manufacturing, allowing for the creation of complex, high-performance metal parts. The various types of metal 3D printing, including Powder Bed Fusion (Selective Laser Melting), Directed Energy Deposition, Binder Jetting, and Metal Extrusion, each offer unique advantages and cater to different applications. As this technology continues to evolve, we can expect even more exciting developments and advancements in the realm of metal 3D printing, transforming the way we design and produce metal components in the years to come.