The Best ASA 3D Printing Settings: Achieving Optimal Results

Introduction:

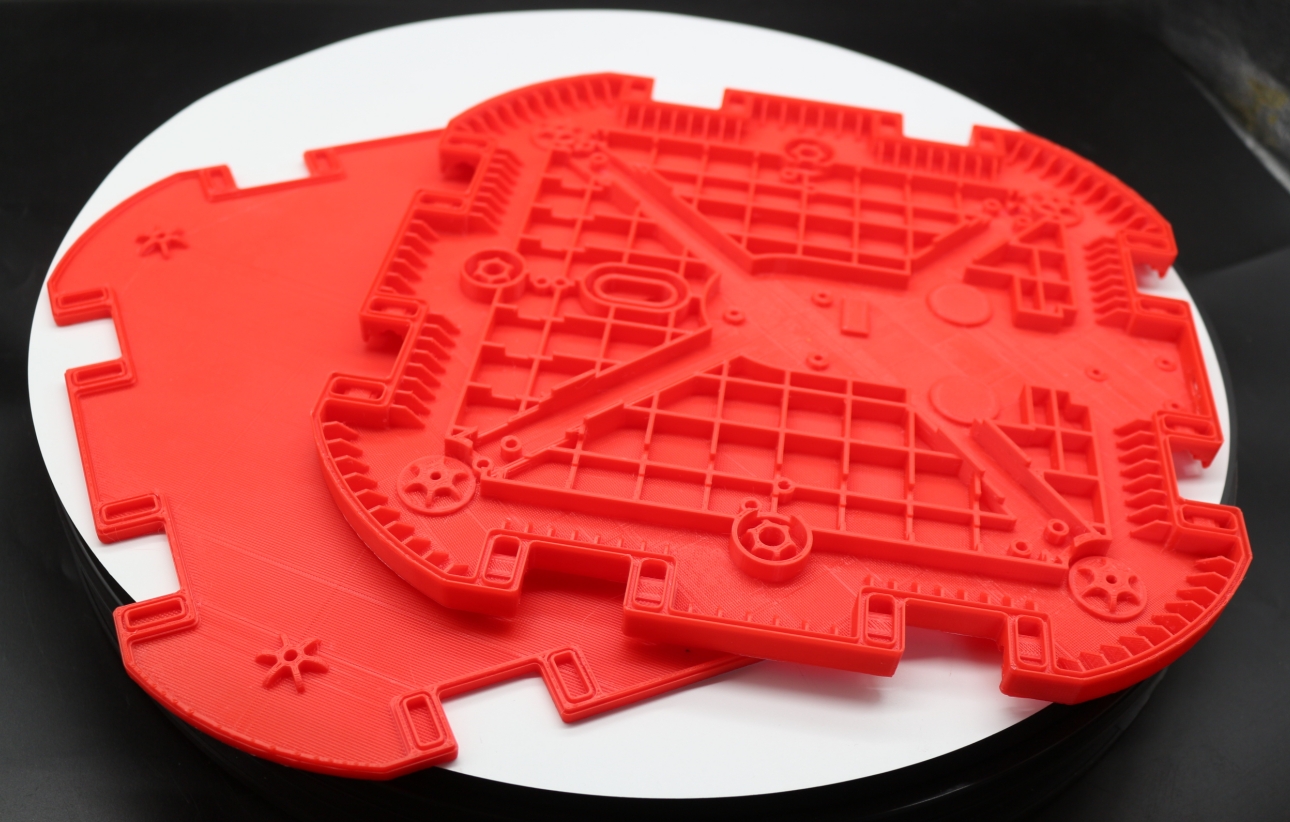

With the growing popularity of 3D printing, enthusiasts are constantly exploring new materials to bring their creations to life. One such material is ASA (Acrylonitrile Styrene Acrylate), which offers excellent strength, durability, and resistance to weathering. To help you achieve the best results with ASA filament, we have compiled a comprehensive guide on the optimal ASA 3D printing settings.

- Nozzle Temperature:

ASA filament generally requires higher nozzle temperatures compared to ABS. Start with a nozzle temperature range of 250-270°C. However, it is crucial to consult the filament manufacturer’s guidelines and adjust the temperature accordingly for your specific printer. Fine-tuning the temperature can significantly impact print quality, so consider experimenting with small temperature increments to find the sweet spot.

- Bed Temperature:

To ensure proper adhesion and minimize warping, a heated bed is essential when printing with ASA. Set your bed temperature between 90-110°C. Preparing the bed with an adhesive such a PEI sheet, or applying a thin layer of ABS juice can further enhance adhesion. Remember to thoroughly clean the print bed between prints to maintain optimal adhesion.

- Print Speed:

ASA filament benefits from relatively slower print speeds compared to other materials. Reducing the print speed helps maintain better layer adhesion and minimizes the risk of overheating. Start with a moderate print speed of around 50-100mm/s and adjust as necessary based on the specific requirements of your print.

- Cooling and Enclosure:

Unlike PLA, ASA is more prone to warping and cracking due to its higher thermal expansion. To mitigate these issues, it is recommended to print ASA in an enclosed chamber, with a consistent chamber temperature of 70°C. Additionally, reducing or disabling part cooling fans can also help prevent warping and promote better layer bonding.

- Layer Height and Wall Thickness:

For optimal print quality, consider using a layer height between 0.1-0.3mm. Smaller layer heights provide finer details but can result in longer print times. Similarly, a wall thickness of at least 1.2mm is advisable to ensure structural integrity and prevent print failures.

- Support Structures and Rafts:

ASA typically requires support structures for overhangs and complex geometries. Consider enabling support structures in your slicer software, ensuring easy removal without damaging the print. Rafts can also be beneficial for improving bed adhesion, particularly for larger prints or those with a high surface area.

- Post-Processing and Finishing:

ASA prints can benefit from post-processing techniques such as sanding, polishing, or acetone vapor smoothing. These methods help achieve a smoother surface finish and enhance the overall appearance of the print. As always, exercise caution and follow appropriate safety protocols when using solvents.

Conclusion:

By optimizing your ASA 3D printing settings, you can unlock the full potential of this robust filament and produce high-quality prints with excellent durability and weather resistance. Experimentation and fine-tuning are key to achieving the best results, so don’t hesitate to adjust the settings based on your printer, filament brand, and specific project requirements. Happy printing!

Disclaimer: The recommended settings provided in this blog are general guidelines and may vary based on specific printer models, filament brands, and personal preferences. Always refer to the manufacturer’s recommendations and conduct your own tests to determine the optimal settings for your setup.