Designing Undercuts for Injection Molding: A Comprehensive Guide

When it comes to injection molding, designing undercuts can be a critical aspect that impacts both the manufacturability and functionality of your part. Undercuts are features that complicate the ejection process, making it essential to understand how to design them effectively. This guide will walk you through the key considerations and best practices for designing undercuts in injection molding.

What Are Undercuts in Injection Molding?

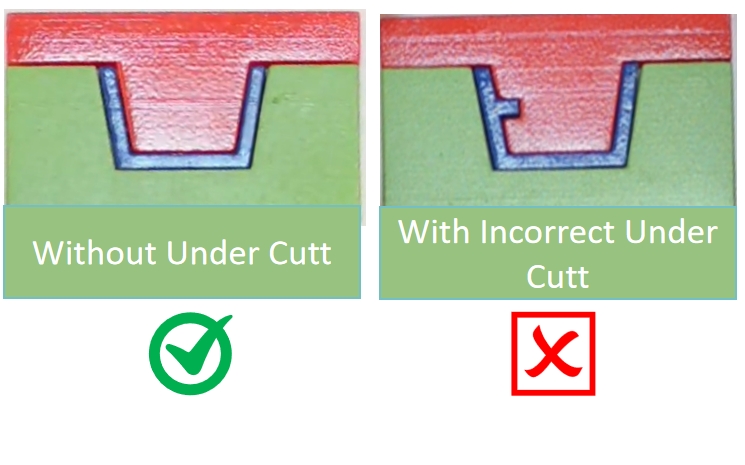

Undercuts are features that prevent the direct removal of a part from its mold without causing damage or requiring additional complex mold actions. These features can include indentations, protrusions, or complex geometries that lock the part in the mold. Common examples are side holes, snap-fits, or internal threads.

Why Are Undercuts Challenging?

Undercuts complicate the mold design and injection molding process because they require special considerations for part ejection. Without appropriate design, undercuts can lead to:

- Increased mold complexity and cost

- Difficulties in part ejection

- Potential damage to the part or mold

- Longer cycle times

When undercutting is inevitable, how should we design?

Key Strategies for Designing Undercuts

- Use Side-Actions and Lifters

Side-actions (or slides) and lifter are mechanical components used to create and release undercuts during the molding process.

– Side-actions: These move perpendicular to the mold opening direction and are ideal for external undercuts. They retract before the part is ejected, allowing smooth removal.

– Lifters: These move at an angle and are used for internal or more complex undercuts. They lift away from the undercut as the mold opens, enabling easy ejection.

Tip: Design your part to minimize the need for side-actions and lifters, as these add to the mold complexity and cost.

- Incorporate Draft Angles

Draft angles are tapered surfaces on the part that facilitate easy ejection from the mold. For parts with undercuts, ensure that you incorporate sufficient draft angles on all surfaces, especially near the undercut areas.

– Internal undercuts: A draft angle of 1-2 degrees is generally recommended.

– External undercuts: Similar draft angles can be applied, depending on the complexity and depth of the undercut.

Tip: Consult with IN3DTEC to determine the optimal draft angles for your specific application.

- Use Flexible Mold Materials

In some cases, using flexible mold materials like elastomers can help in accommodating undercuts without the need for complex mold mechanisms. These materials can deform slightly during the ejection process, allowing the part to be released more easily.

Tip: This approach is suitable for low-volume production runs or when the undercut features are relatively small and simple.

- Optimize Part Geometry

Designing your part with undercut features that are easy to mold can significantly reduce complications. Here are a few tips:

– Reduce the depth of undercuts: Shallow undercuts are easier to manage than deep ones.

– Simplify the geometry: Avoid intricate details that complicate mold design.

– Align undercuts with the parting line: Whenever possible, align the undercut features with the mold’s parting line to simplify the mold design.

Tip: Use CAD software to simulate the molding process and identify potential issues early in the design phase.

Material Considerations

The material you choose for your part can influence how you design undercuts. Different materials have varying shrinkage rates, which can affect the mold design and the final part dimensions. Common materials used in injection molding include:

– Thermoplastics: These are the most commonly used materials and offer good flexibility and durability.

– Elastomers: These materials are more flexible, making them ideal for parts with complex undercuts.

– Thermosetting plastics: These materials are more rigid and may require more careful design to accommodate undercuts.

Tip: Please feel free to contact us to understand the specific properties and behavior of the material you are using.

Conclusion

Designing undercuts for injection molding is a challenging but essential task that requires careful consideration of mold design, part geometry, and material selection. By using side-actions and lifters, incorporating draft angles, choosing flexible mold materials, and optimizing part geometry, you can create parts with undercuts that are both functional and manufacturable.

Remember, collaboration with your mold designer or consult with IN3DTEC is key to ensuring a successful injection molding process. By following these guidelines, you can minimize complications and achieve high-quality molded parts.