Exploring the Best 3D Printing Settings for HIPS

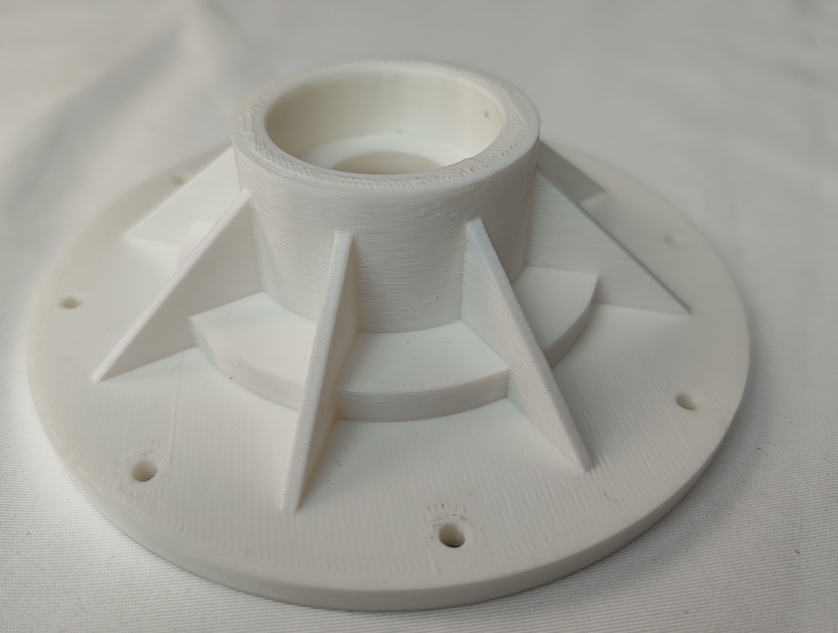

High Impact Polystyrene or HIPS is a standout choice in the world of 3D printing. Known for its strength, durability, and solvability in D-limonene, HIPS is frequently used both as a primary printing material and as a support structure for more complex prints. In this blog, we’ll explore the best 3D printing settings for HIPS to help you achieve optimal results.

Why Choose HIPS?

HIPS offers several advantages that make it a popular choice among 3D printing enthusiasts:

Strength and Durability: HIPS produces strong and impact-resistant prints.

Ease of Use: It’s relatively simple to print with HIPS compared to other filaments.

Support Material: When used as a support material, it easily dissolves in D-limonene, providing clean, detailed prints without manual support removal.

Optimal 3D Printing Settings for HIPS

- NozzleTemperature

To achieve the best results with HIPS, a nozzle temperature between 230°C and 250°C is recommended. Starting at 240°C, you can gradually increase the temperature if you notice issues such as under-extrusion.

- Bed Temperature

HIPS has a tendency to warp without a heated bed. Therefore, keeping the bed temperature between 90°C and 110°C is crucial. This helps ensure that the print adheres properly to the bed and minimizes warping.

- Print Speed

A moderate print speed of 60 to 100 mm/s is ideal for HIPS.

- Bed Surface

To improve adhesion and prevent warping, consider using:

Glass for a smooth surface, applying a glue stick or hairspray to the bed surface can further enhance adhesion. Or PEI sheet.

- Retraction Settings

Proper retraction settings help minimize stringing and oozing. For HIPS, a retraction speed of 40 to 50 mm/s and a retraction distance of 1 to 3 mm usually works best. It is important to note that different printers have different types of extrusion, so it is best to consult with the 3D printer equipment provider.

- Cooling

HIPS prints better with minimal cooling. Turn the cooling fan off or keep it at a very low setting to avoid warping or layer separation.

- Printing Environment

Printing HIPS in an enclosed chamber can prevent rapid cooling and help maintain a stable temperature, which is crucial for reducing warping and cracking. 50℃minimum is recommended.

- Adhesion and Removal

Using adhesion aids like a brim or raft, can significantly improve bed adhesion, reducing the chances of warping.

- Layer Height

For optimal results, select a layer height between 0.1 and 0.3 mm. Finer layers provide better detail but take longer to print, so adjust according to your needs.

Troubleshooting Tips

Warping: Ensure an adequate bed temperature and use adhesion aids. An enclosed chamber can also help.

Layer Separation: Check and maintain a consistent ambient temperature, increase bed temperature, or print in an enclosure.

Under-Extrusion: Adjust the nozzle temperature and make sure that the filament is not exposed to moisture as it can absorb humidity.

Final Thoughts

HIPS is a versatile and reliable filament for both standalone and support prints. By carefully tuning the settings mentioned above, you can maximize the benefits of HIPS and produce high-quality, durable prints. Whether you’re a beginner or a seasoned 3D printing enthusiast, these settings can significantly enhance your 3D printing experience with HIPS.