How 3D Scanning is Revolutionizing Automotive Restoration

Restoring classic cars to their former glory is a passion for many automotive enthusiasts. However, it often involves significant challenges, from finding replacement parts to ensuring precise fits for components that may no longer be manufactured. Enter 3D scanning — a cutting-edge technology that is transforming the world of automotive restoration by bringing precision, efficiency, and creativity to the process.

In this blog, we’ll explore how 3D scanning is making a difference in restoring vintage and classic cars, and why it’s becoming an indispensable tool for restoration professionals.

What is 3D Scanning?

3D scanning is a process that captures the physical dimensions of an object using lasers, structured light, or photogrammetry. The result is a highly accurate 3D digital model that can be used for analysis, modification, or reproduction.

For automotive restoration, 3D scanning enables precise documentation of components, from entire car bodies to small, intricate parts, making it easier to replicate or repair them.

How 3D Scanning Benefits Automotive Restoration

- Reverse Engineering for Hard-to-Find Parts

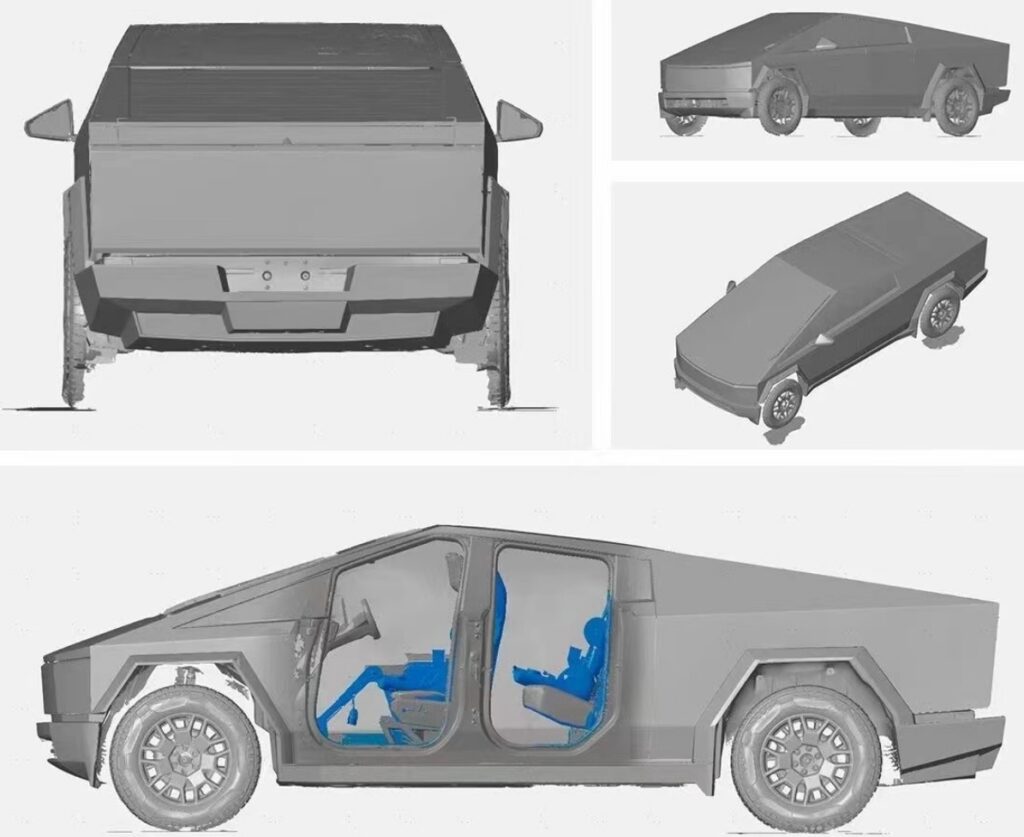

Many classic cars have parts that are no longer manufactured, and finding replacements can be nearly impossible. With 3D scanning, these parts can be reverse-engineered by creating a digital model of an existing piece or its damaged remnants.

Once scanned, the model can be repaired virtually, and the part can be reproduced using methods like CNC machining, 3D printing, or casting. This process is faster and often more cost-effective than traditional manufacturing techniques.

- Precise Fit and Alignment

Restoration often involves replacing or repairing components like fenders, bumpers, and engine parts. Achieving a perfect fit is crucial for both functionality and aesthetics.

3D scanning ensures that new or restored parts align seamlessly with the existing structure.Scanned data can be used to detect misalignments, allowing for precise adjustments before production.

- Recreating Missing Components

When original parts are entirely missing, restoration experts can scan matching parts from identical models or recreate them from archive photographs. The 3D model serves as a blueprint for producing an exact replica, ensuring authenticity and accuracy in the restoration. - Streamlining Bodywork Repairs

Damaged car bodies with dents, rust, or deformation can be scanned to assess the extent of the damage. The resulting digital model allows restoration professionals to:

- Create templates for sheet metal fabrication.

- Plan and execute repairs with greater precision.

- Save time compared to manual measurements and adjustments.

- Preserving History with Digital Archives

3D scanning creates detailed digital records of classic cars and their components, preserving them for future generations. These archives:

- Serve as references for future restorations.

- Allow car enthusiasts and museums to share accurate virtual models.

- Contribute to maintaining historical accuracy in the automotive world.

- Enhanced Collaboration with Modern Tools

Restoration projects often involve collaboration between designers, machinists, and fabricators. 3D scanning provides a common digital platform where all stakeholders can access and modify the data. This minimizes errors and ensures a cohesive workflow, from design to final assembly.

Real-World Applications of 3D Scanning in Automotive Restoration

- Classic Car Replicas: Companies specializing in vintage replicas use 3D scans to ensure their reproductions match the original design.

- Racing Legends Revived: Historic race cars with unique bodywork and components can be restored to their exact specifications using 3D scanning and digital modeling.

- Customized Restoration: Enthusiasts who want to modernize classics with updated features (e.g., new engine mounts or interior upgrades) can use scanned data to design custom solutions.

Are you looking for a reliable and professional 3D scanning service provider? Look no further than IN3DTEC! We deliver exceptional precision of up to ±0.01mm, with a standard lead time of just 2 working days. Our services are competitively priced, starting at only USD 40.00. Share your project details with us today at [email protected], and let us help bring your ideas to life!

Challenges and Considerations

While 3D scanning is a game-changer, it’s important to consider:

- Cost of Equipment: High-precision scanners can be expensive, though costs are decreasing with advances in technology.

- Skill Requirement: Proper use of 3D scanning and modeling tools requires training and expertise.

- Post-Processing Time: Converting raw scan data into usable models for manufacturing can take time and specialized software.

Conclusion

3D scanning is not just a tool; it’s a bridge between the past and the future of automotive restoration. By enabling precise reproduction, customization, and documentation of classic cars, this technology is empowering enthusiasts and professionals to restore and preserve automotive history like never before.

Whether it’s creating a missing part, repairing a damaged body, or sharing a digital archive of a timeless classic, 3D scanning is revolutionizing how we approach automotive restoration. As the technology continues to evolve, its impact on the automotive world will only grow.