1020mm(X) x 970mm(Y) x 985mm(Z)

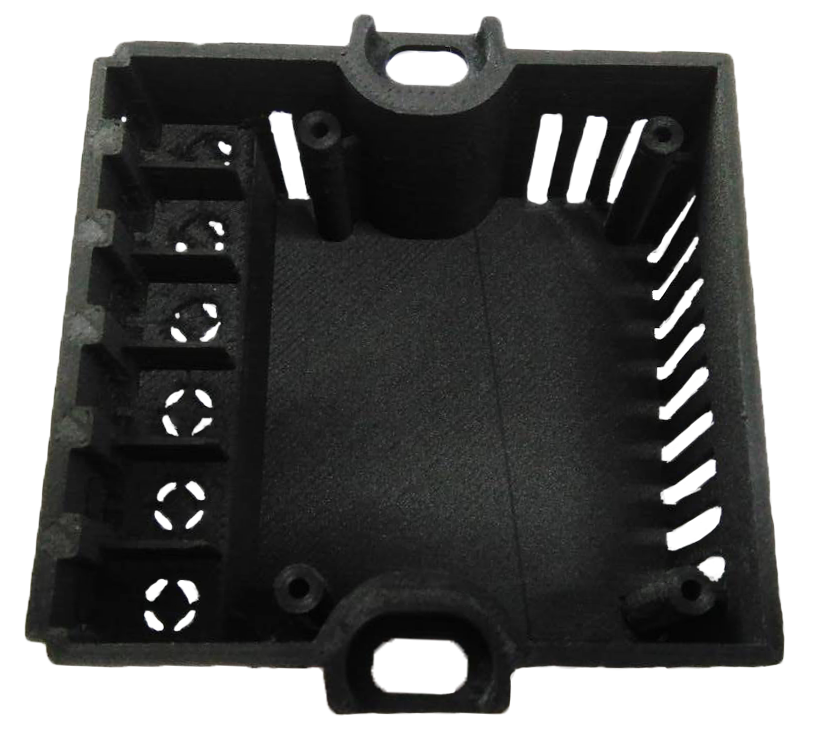

,0.2mm layer thickness

0.2mm layer thickness

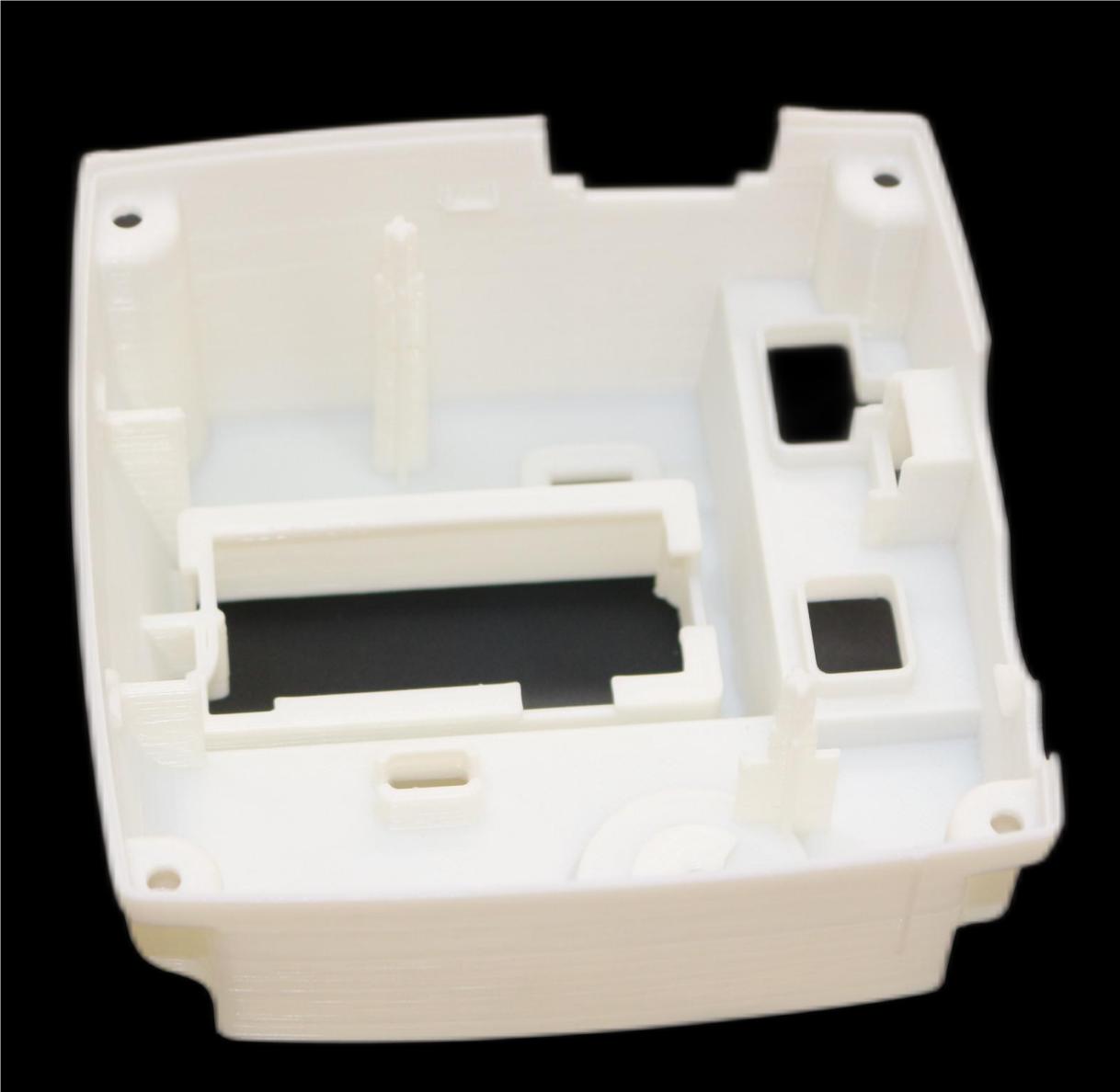

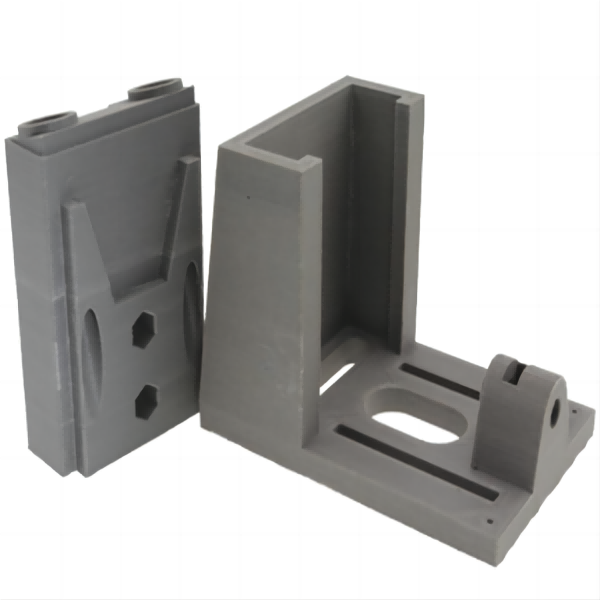

610mm(X) x 508mm(Y) x 508mm(Z), 0.15mm layer thickness

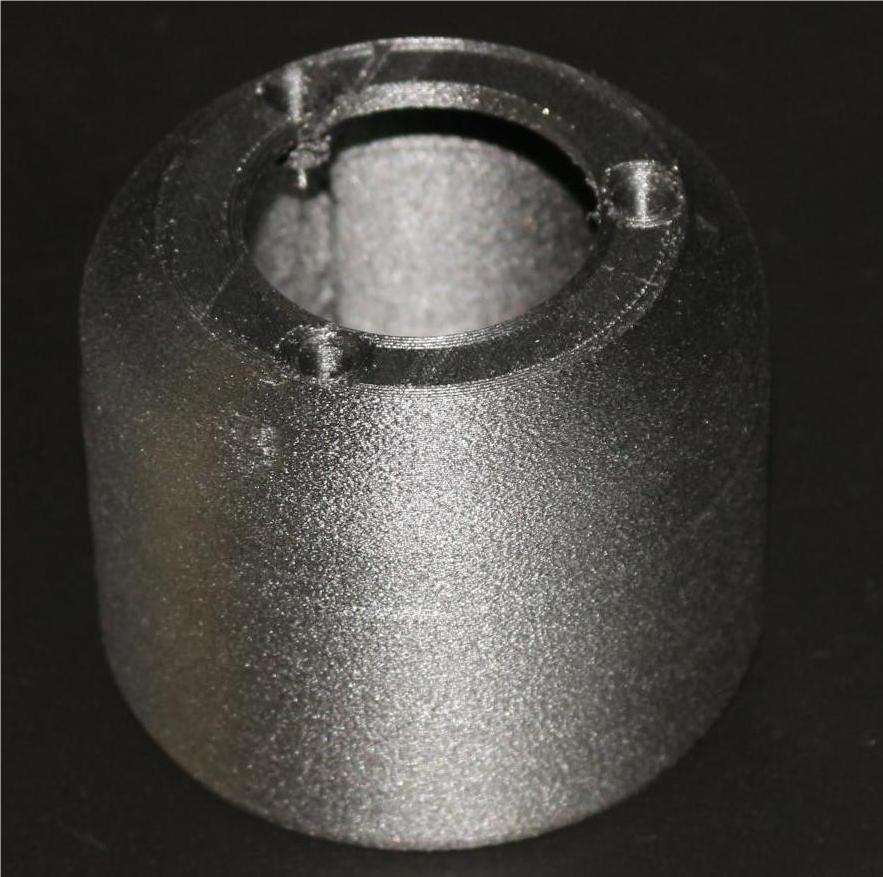

380mm(X)×284mm(Y)x380mm(Z)

0.05mm layer thickness

0.05mm layer thickness

0.05mm layer thickness

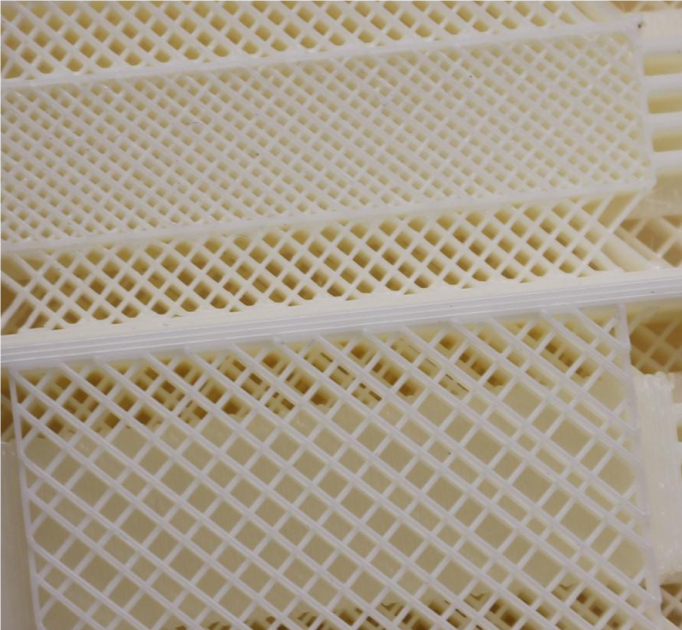

1900mm(X)×1000mm(Y)x800mm(Z)

Layer thickness:0.05mm

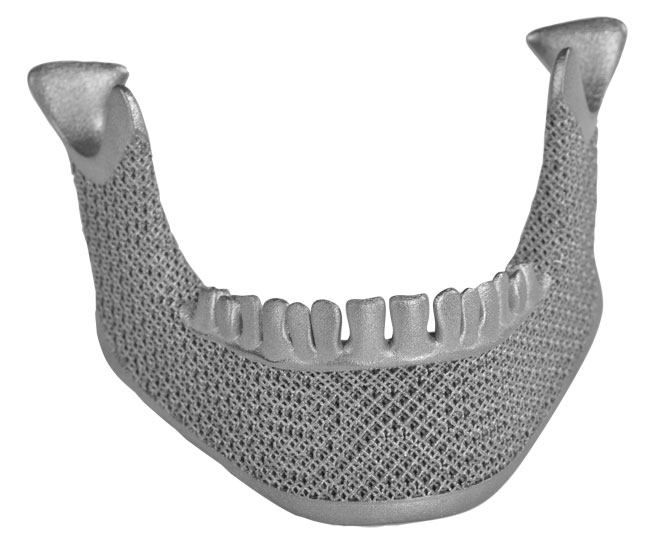

400mm(X) x 400mm(Y) x 400mm(Z), 0.03 layer thickness

130mm(X) x 130mm(Y) x 130mm(Z), 0.03mm layer thickness

400mm(X) x 400mm(Y) x 400mm(Z), 0.03 layer thickness

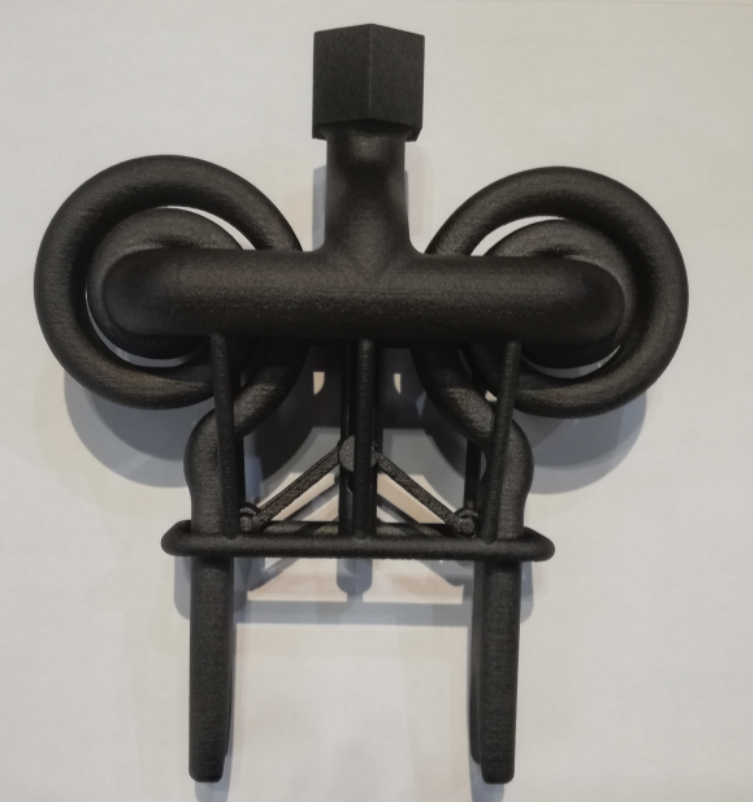

650mm(X) x 350mm(Y) x 520mm

,0.05 layer thickness

500mm(X) x 330mm(Y) x 400mm(Z), 0.05 layer thickness

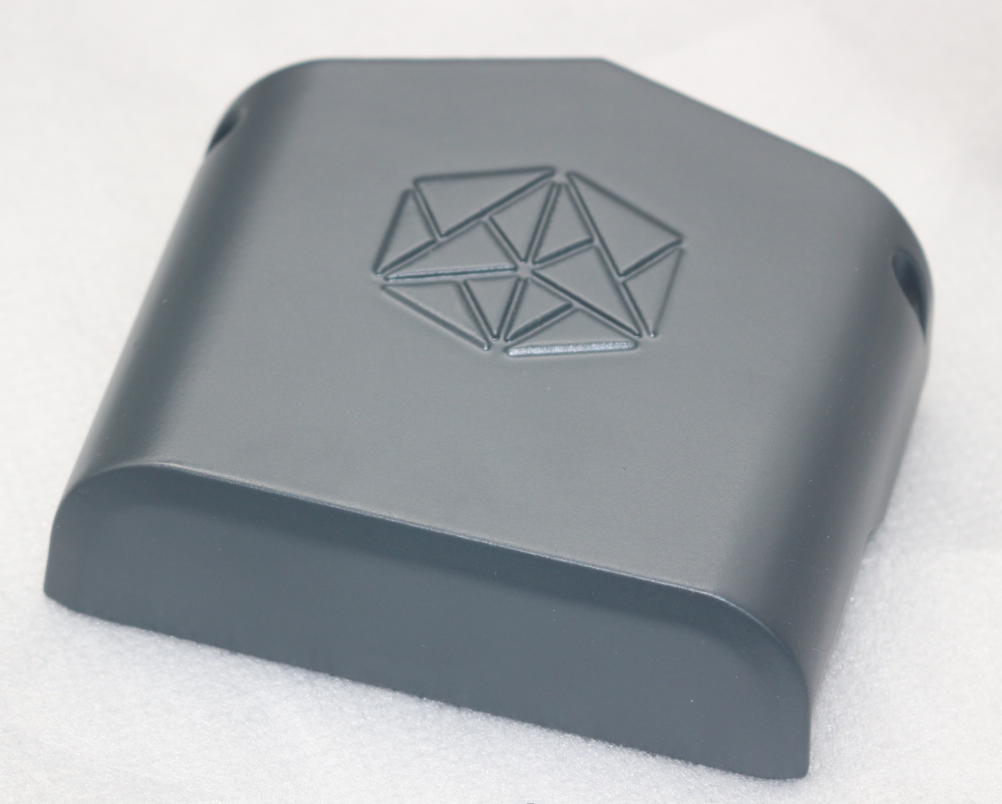

It creates a matte and uniform surface finish.

It creates a glossy satin, uniform, and nice look surface finish.

It creastes a polished and glossy surface finish.

It creates a slighly granular, matte and deburred surface finish.

It creates a slighly granular, matte and uniform surface finish.

It creates a satin glossy, uniform, and nice look surface finish.

It creastes a polished and glossy surface finish.

It creates a slighly granular, matte and uniform surface finish.

It creates a satin glossy, uniform, and nice look surface finish.

It creastes a polished and glossy surface finish.

It creates a slighly granular, matte and uniform surface finish.

It creates a slighly granular, matte and uniform surface finish.

It creates a satin glossy, uniform, and nice look surface finish.

It creastes a polished and glossy surface finish.

It creates a slighly granular, matte and uniform surface finish.

It creates a satin glossy, uniform, and nice look surface finish.

It creastes a polished and glossy surface finish.

It creates a slighly granular, matte and uniform surface finish.

It creates a satin glossy, uniform, and nice look surface finish.

Polypropylene (PP) is one of the most commonly used thermoplastics in the world.

Nylon 6 has Great wear resistance, and is ideal for outdoor products.

PA11 is a bio-based and temperature-stable material that features a high impact resistance and is commonly used to print strong and functional parts.

Higher details, more flexible and durable than PA12.

Biocompatible & Skin-free

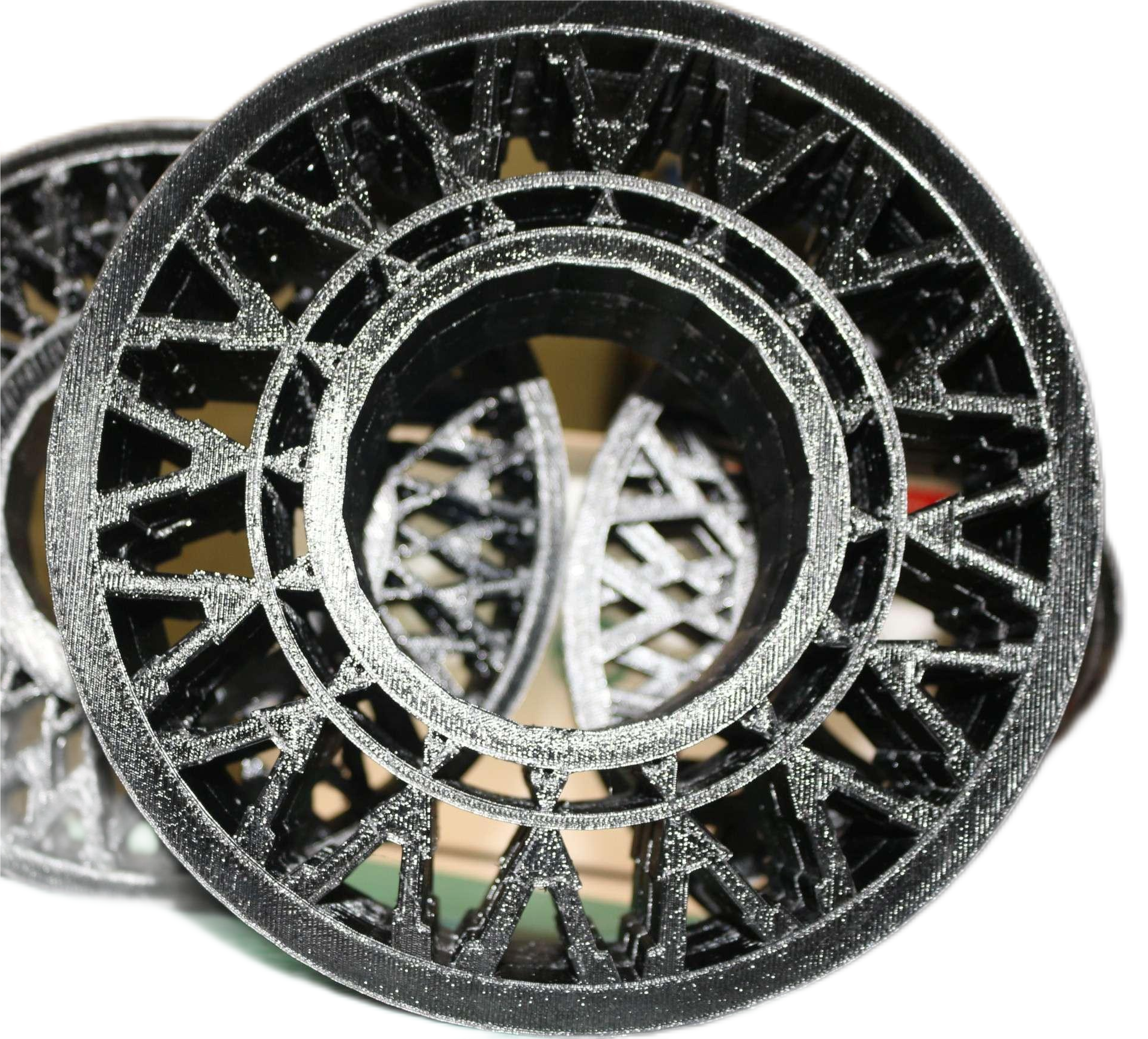

Developed by HP, MJF Nylon is a widely used material for strong and detailed end-use parts and prototypes.

Great wear resistance, Strong layer adhesion (Semi-Crystalline), Can be used up to 180°C/356F

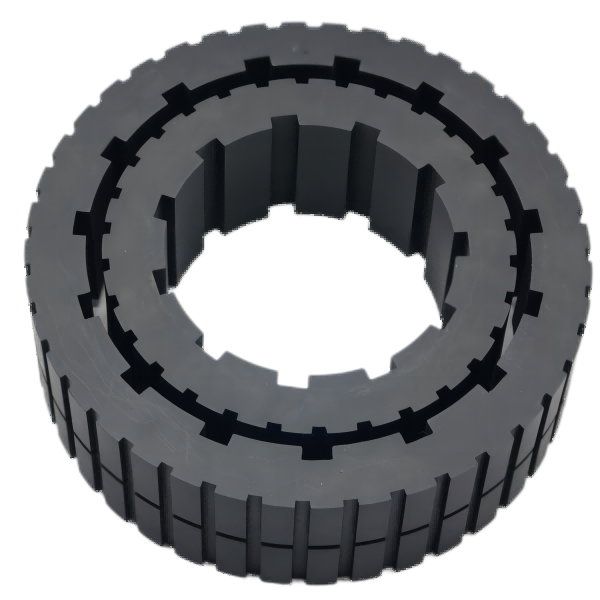

Nylon PA12 (Polyamide) is a strong and heat-resistant material commonly used to print strong and functional parts.

Comapred with balanced printing mode, fast mode is much cheaper, but lower smoothness and more visible lines.

Comapred with balanced printing mode, fast mode is much cheaper, but lower smoothness and more visible lines.

Stronger, Smoother surface, uniform color and water-proof.

Smoother surface, uniform color, customized color

Uniform color, stronger, smoother, and water-proof.

Uniform color, stronger, smoother, and water-proof.

Somos® Evolve is the perfect material for strong, highly detailed functional prototypes and parts that need to withstand continuous usage.

Somos® Taurus delivers excellent surface quality and reduces job times for highly detailed parts and isotropic mechanical properties

Tough resin is a perfect choice for strong, detailed functional prototypes and parts that need to withstand stress and strain.

250C/482F heat resistannce, smooth surface.

Cast-able resin is ideal for investment casting, we can do IC in-house as well. It needs manual quote then.

High accuracy, smooth surface, 140C /280F heat resistance under 0.45Mpa.

Tough resin is a perfect choice for strong, detailed functional prototypes and parts that need to withstand stress and strain.

Somos® Ledo is a photosensitive resin material with tough texture and excellent waterproof performance developed by DSM.

PP like Resin, high detail and smooth surface.

High details with smooth & nice surface finish.

Full transparent, water-clear Resin.

High details and prototyping resin with smooth surface.

Translucent.

High details with smooth & nice surface finish.

High details and prototyping resin with smooth surface.

Glass fiber reinforced Nylon 6 is super strong, heat resistace and preforms excellent mechanical properties

Glass reinforced nylon12 is more heat resistance, stronger and more durable than nylon

More heat resistace than Nylon 12, stronger and more durable.

Carbon- Fiber reinforced Nylon 66 based 3D printing filament with improved dimensional stability and mechanical properties.

Carbon fiber filled ABS is stronger than normal ABS, more durable and heat resistance

Carbon filled PC has higher heat resistance than PC, stronger and more durable.

Waterproof, stronger and stiffer. Ideal for functional part

Carbon fiber filled PEEK has High dimensional stability and weight-to-strength ratio, Higher stiffness at high temperatures, HDT A 315°C allows short term usage at even higher temperatures, chemical resistance properties

Glass fiber filled PEEK has high dimensional stability,high electrical insulation, HDT A 315°C allows short term usage at even higher temperatures properties

Glass fiber filled Nylon creates functional parts with heat resistance(190C), high strenth and chemical resistance properties

PETG is a waterproof material, durable and low cost

ASA is a UV-resistance material which is suitable for outdoor products

PLA is the cheapest material ideal for prototypes and consumer products

ABS is a popular plastic ideal for functional parts, it is easily to be polished and colored.

Polycarbonate is an industrial-grade thermoplastic with high heat resistance and high strength.

It combines the good properties of PC and ABS.

Polycarbonate is an industrial-grade thermoplastic with high heat resistance and high strength.

Flame Retardant PC has improved strength and thermal properties along with a flame retardant level of UL94: V-2. It is ideal for printing strong, functional parts that must withstand heat.

Peek has all the advantages of high-performance materials, such as 260C heat resistance, chemical resistance, wearable, UL94-V0,etc.

Flame retardant, Heat resistance, excellent chemical resistance make ULTEM1010 is very popular in high performance plastics.

ULTEM9085 is flame retardant material with heat resistace(180c), high strength properties.

200C degree resistance and chemical resistance make PPS ideal for parts need high performance and functional.

PEKK is a good choice if you are looking for a plastic to replace metal

PPSU is ideal for medical devices, casing of aerospace and automotive.

FDM TPU creates functional and wearable parts

SLS TPU a rubber-like material suitable for functional prototypes.

MJF TPU is a rubber-like material suitable for functional prototypes and wear-resistant parts.

Shore 60A, Elastic but not durable. Not suitable for parts have tiny details.

Full Transparent

Dark Grey

Dark Navy Color

Translucent Color

Chocolate Color

Amber Color

Off-white Color