Dental 3D printing guide

3D printing technology and the dental industry is a natural match.

First of all, the tooth characteristics of each patient in the dental industry are different, so the generated 3D data are also different, and 3D printing technology can achieve personalized production.

Secondly, the structure of human teeth is relatively complex. Traditional artificial teeth will lead to the deviation of the accuracy of dental medical products, which will lead to the discomfort of patients. 3D printing technology can meet the needs of accurate, complex and customized dental products.

Finally, dental patients always hope to get fast and effective treatment, the traditional processing method is slow, and 3D printing technology can accelerate the progress of the treatment process.

Dental scanner

In dental care, the part of dental scanners is vital. Therefore, the most recent innovation and appearance of new and further developed dental scanners are hotly debated issues among dental experts.

Dental scanners take superior quality optical impressions of the intricate and inaccessible spots inside the oral cavity. They’re accessible in intraoral and lab forms and can be as simple to work as utilizing a cell phone.

Of basic significance is the product used to dissect the caught information, propose treatment, and set up a model for 3D printing. Recognizing highlights of a dental 3D scanner are the speed at which it checks, the amount and nature of the information it procures, and the knowledge (simulated intelligence) it shows in gathering or disposing of information. The expense differs fundamentally relying upon brand and functionalities.

The main application of 3D printing technology in dentistry

Dental implant

Implant is a kind of dental implant which is supported by the implantation of artificial root (implant) in the alveolar bone tissue of the mouth and the restoration of the crown on the artificial root. The traditional cone column implant needs to experience the steps of minimally invasive extraction, preparation of implant hole, bone powder implantation, collagen coating, embedded healing, second stage operation, crown making and wearing. The treatment period is about 6 to 8 months, the doctor’s operation time is about 8 hours. For complex situations, time and costs will increase further. At the same time, there are many shortcomings in this way, including because the implant teeth and the extraction socket are not closed, the implant needs bone powder implantation and is difficult to repair immediately after extraction.

3D printing implant can directly form the whole tooth body with root. It only needs the steps of minimally invasive extraction, implant and crown restoration, and can realize seamless combination with the original alveolar, reduce the pain of patients. The treatment is one to two hours, and the doctor’s operation time is only half a small time, and the cost is greatly reduced.

In the field of oral implant, pure titanium (or alloy) is widely used because of its good biocompatibility, mechanical properties and corrosion resistance. Implant materials include metal implants, ceramic implants, carbon implants, polymer implants, composite materials, etc; Crown materials include gold, cobalt chromium alloy, nickel chromium alloy, ceramic alloy and other metal materials, as well as zirconia all ceramic, resin and so on. SLM (selective laser melting) is the main printing technology for dental implants and metal crowns, while SLA (light curing molding) and DLP (digital light processing) are the main printing technologies for dental crown and bridge casting models.

Aligners and Night guards

The most common application of 3D printing in dentistry is the creation of transparent aligners and night guards. Aligners, which serve as alternatives to braces, have become especially popular because they’re relatively easy to produce, use, and hide (via transparency).

The process starts with the patient’s teeth being scanned to generate a 3D model of the teeth. To create an aligner, the digital model is adjusted according to the desired shape, while night guards require minimal adjustment, as the purpose is to fit the teeth as they are.

To make the model a reality, one of two methods is used. The first is to 3D print a model of the patient’s teeth, then use a vacuum to form a plastic sheet over the model. When hardened, this plastic becomes the aligner or guard. Alternatively, the scan of the patient’s teeth can be used to design the aligner or guard digitally, which can then be 3D printed. Naturally, this requires a very high-definition dental 3D printer and special resin.

The primary benefit of using 3D printing to produce aligners and night guards is speed. It takes just hours to produce a full batch. This technology also makes it easier to fully customize each item, as it’s created from precise scans of the patient’s teeth.

Dentures

3D printing dentures, another key application of dental 3D printing, significantly saves time and money. Where it would usually take days or weeks for a model denture to be created using conventional means, 3D printing makes that happen in a jiffy.

The workflow is similar to other dental 3D printing applications. It involves scanning, designing, printing, washing, and curing. The end product is also processed and polished to give a superior finish and aesthetic value. For dentures, the base and the teeth are printed separately, then joined (just before curing) by removing the support from the denture base and affixing the printed teeth.

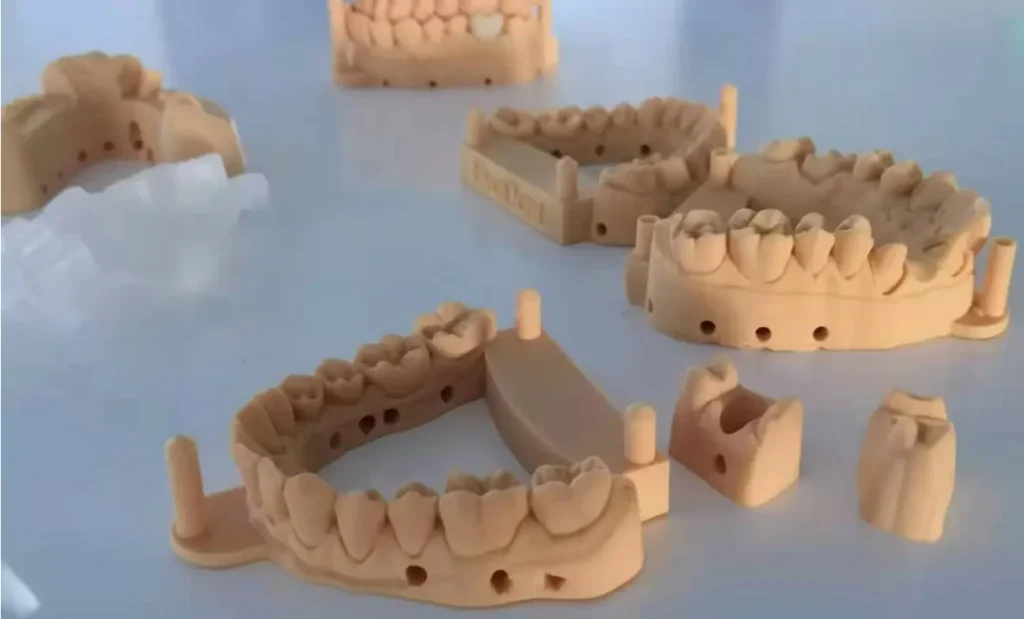

Models

In dentistry, it’s vital to get things right the first run through, and dental 3D printers guarantee this. A specialist can print a model of a patient’s mouth and confirm that their implant, crown, or aligner will fit with precision.

3D printed dental models are not difficult to make, requiring just a scan of the patient’s mouth. And because these models aren’t actually placed in anyone’s mouth, they don’t require any specifically-developed technology or resin. Simple, yet useful.

Surgical guides

As with most medical procedures, oral surgery requires precision. Because of this, a 3D printed guide designed to fit perfectly in a patient’s mouth is an indispensable asset for a dentist.

Similar to the process for creating an aligner, a model is created based on a scan of the patient’s mouth, but with openings exactly where surgery is to be performed. Surgical guides can be printed in the same resin as aligners and night guards, and they can be created quickly on any dental 3D printer.

The thriving future

The report released by Transparency Market Research (TMR) stated that the market value of dental 3D printing is expected to reach 3441 million US dollars by the end of 2025. During the forecast period from 2017 to 2025, the compound growth rate of the market is expected to be 16.5%.