Design Tips For SLA 3D Printing

What is SLA 3D Printing?

SLA (Stereolithography) 3D printing is a type of 3D printing technology that uses a liquid resin and a UV laser to build objects layer by layer. In SLA 3D printing, a 3D model is first sliced into thin layers by specialized software. The 3D printer then uses a UV laser to selectively cure the liquid resin, solidifying it into the desired shape one layer at a time.

The printer bed contains a tank filled with liquid resin, and a build plate is lowered into the resin. The UV laser is then used to trace the shape of the first layer of the object, causing the resin to solidify and adhere to the build plate. The build plate is then lowered by one layer, and the process is repeated until the entire object is completed.

What is the advantages of SLA 3D Printing?

SLA 3D printing is capable of producing highly detailed and accurate objects with a smooth surface finish. It is often used in the production of rapid prototyping, housing & casing, any kind of models, jewelry, dental, and other high-precision applications.

8 Design tips you should know for SLA 3D Printing

Overhangs: Consider the orientation of your model in the build volume. Try to avoid parts with large overhangs as it printing models with large overhangs as it may cause the model to fail during printing.

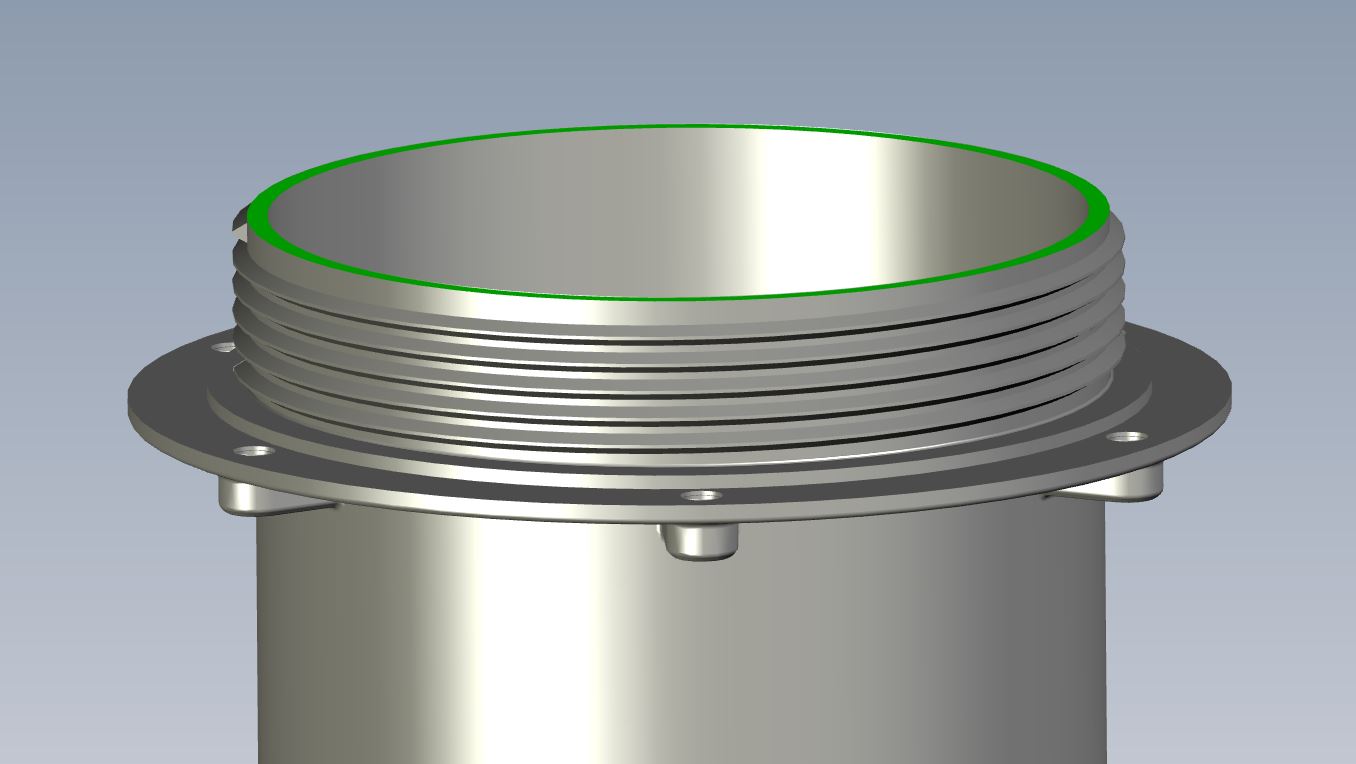

Wall thickness: Ensure that the wall thickness of your model is sufficient for the SLA 3D printer to print. Typically, a wall thickness of at least 0.6mm is recommended. Thinner walls may cause the model to be brittle and break easily. Too much thicker wall may cause deformation & warping. For most parts, a wall thickness ranging from 3mm to 8mm is generally sufficient.

Support structures: Supports are necessary for printing models with overhangs and other complex geometries. Make sure that your design allows for the easy removal of supports, and consider incorporating non-removable supports into your design where necessary.

Hollowing: Consider hollowing out your model to save on material and reduce printing time. This also helps to reduce the weight of your model, making it easier to handle and transport.

Resolution: SLA 3D printers are capable of printing models with high resolution. Use this to your advantage by designing models with intricate details that can be easily captured by the printer.

Material: Choose the appropriate material for your model. Different materials have different properties and are suited for different applications. Learn more about SLA 3D printing material selecting.

Post-processing: After printing, your model may require post-processing to remove support structures, sanding, and polishing. Consider this when designing your model and leave enough room for post-processing.

Assembly gap: Make sure your designed model has enough assembly gap. 0.15 to 0.2mm at each side is recommended.

Overall, designing for SLA 3D printing requires attention to detail and an understanding of the printing process. With these tips, you can create high-quality models that are optimized for SLA 3D printing.