- Author

- 25 February 2026

Everything You Need to Know About CNC Milling in 2023

Introduction:

In the world of manufacturing, Computer Numerical Control (CNC) milling has emerged as a leading technology, revolutionizing the way we produce complex parts and prototypes. As we delve into 2023, the advancements in CNC milling continue to shape the industry, offering greater precision, efficiency, and flexibility. Whether you’re new to CNC milling or seeking to stay updated with the latest trends, this blog post will provide you with all the essential information you need to know about CNC milling in 2023.

1. What is CNC Milling?

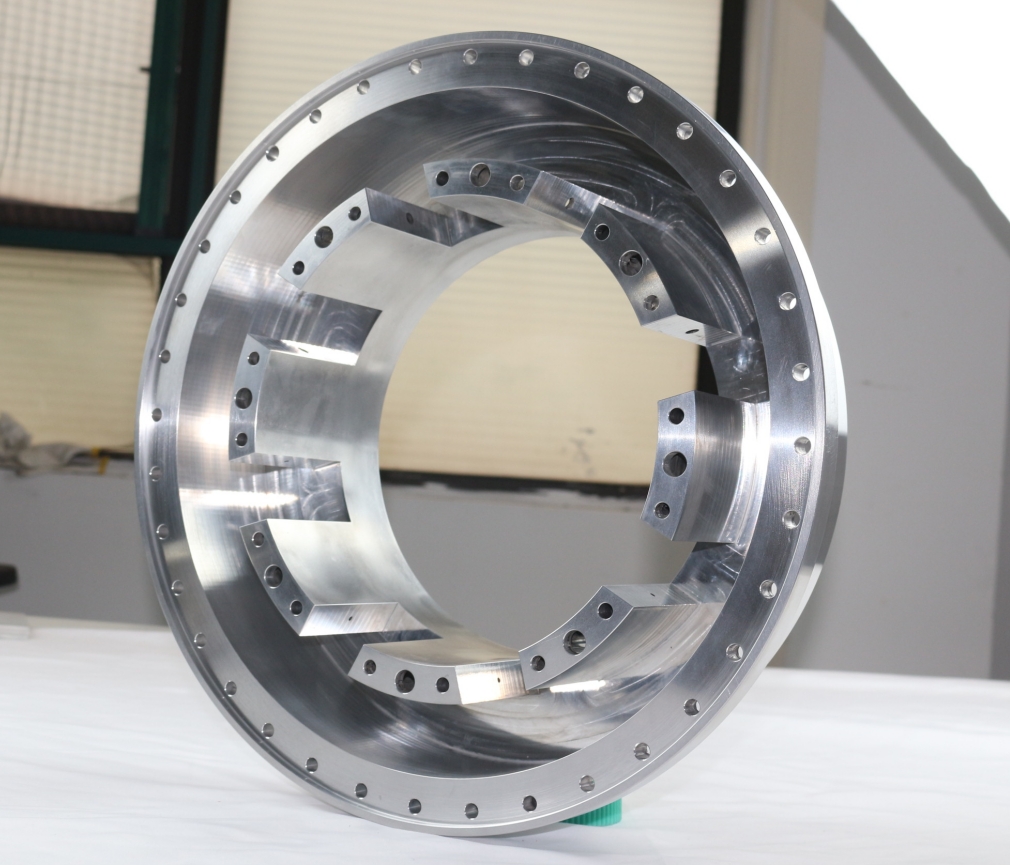

CNC milling is a machining process that utilizes computer-controlled machines to remove material from a workpiece. It involves precise cutting tools that move along multiple axes, following instructions from a computer program. This technology enables the production of highly accurate and intricate components for various industries, including automotive, aerospace, electronics, and more.

2. What are the advantages of CNC Milling?

CNC milling offers several advantages over conventional milling techniques. These include:

- High precision and accuracy: CNC machines can achieve extremely tight tolerances and produce complex geometries with consistent results.

- Enhanced productivity: With automated operations and continuous machining capabilities, CNC milling reduces production time and increases efficiency.

- Versatility: CNC milling machines can work with a wide range of materials, including metals, plastics, composites, and even advanced materials like titanium or carbon fiber.

- Flexibility: Changes in design can be easily implemented by modifying the computer program, allowing for rapid prototyping and customization.

3. What is the latest trend of CNC Milling in 2023?

Keeping up with the trends in CNC milling can help you optimize your manufacturing processes. Here are some notable trends in 2023:

- Integration of Artificial Intelligence (AI): AI algorithms are being incorporated into CNC milling machines, enabling real-time monitoring, predictive maintenance, and adaptive machining strategies.

- Increased Automation: Automation is gaining momentum, with advancements in robotics and machine learning. This trend focuses on reducing human intervention, improving productivity, and ensuring consistent quality.

- Multi-axis Machining: CNC milling machines with multi-axis capabilities, such as 5-axis or even 9-axis machines, are becoming more prevalent. This allows for complex part production in a single setup, reducing the need for multiple machine operations.

- Additive Manufacturing Integration: The integration of CNC milling with additive manufacturing processes, such as 3D printing, is creating hybrid manufacturing systems. These systems combine the benefits of both technologies, enabling the production of intricate parts with varying material properties.

4. What are the common CNC CNC Milling Machine Types?

- Vertical Machining Centers (VMCs): These machines have a vertical spindle orientation, with the cutting tools positioned vertically. VMCs are commonly used for 3-axis machining and are well-suited for manufacturing flat or prismatic parts.

- Horizontal Machining Centers (HMCs): HMCs have a horizontal spindle orientation, and the workpiece is positioned horizontally. These machines are ideal for heavy-duty machining and are often used for applications that require multiple-sided machining or large-scale production.

- 5-Axis Machining Centers: 5-axis machines can move the cutting tool along five different axes simultaneously, allowing for the production of highly complex and contoured parts. These machines are widely used in aerospace, automotive, and medical industries.

- CNC Mill-Turn Centers: Mill-turn centers combine both milling and turning capabilities in a single machine. They can perform a range of operations, including milling, drilling, turning, and threading, offering increased versatility and reducing the need for multiple machines.

5. What is the role CAD/CAM Software in CNC Milling?

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software play a crucial role in CNC milling. CAD software is used to design the 3D models of the parts, while CAM software generates the toolpaths and instructions for the CNC machine. These software tools allow for efficient design modifications, optimization of toolpaths, and simulation of machining operations before actual production.

6. Cutting Tools and Toolholders:

The selection of cutting tools and toolholders is critical for achieving high-quality results in CNC milling. Common types of cutting tools used in milling include end mills, face mills, drills, and reamers. These tools come in various sizes, geometries, and coatings to suit different materials and machining operations. Toolholders securely hold the cutting tools in the spindle and provide stability during machining.

- 7. Workholding and Fixturing:

Workholding refers to the methods and devices used to secure the workpiece during CNC milling. Proper workholding is essential for stability, accuracy, and repeatability. Common workholding solutions include vises, clamps, fixtures, and rotary tables. The choice of workholding depends on the size, shape, and material of the workpiece, as well as the machining requirements.

8. Toolpath Optimization:

Optimizing the toolpaths is crucial for efficient and precise CNC milling. Toolpath optimization involves considering factors such as cutting time, tool life, surface finish, and chip evacuation. Advanced CAM software can optimize toolpaths to minimize unnecessary movements, reduce cycle times, and maximize the utilization of cutting tools.

9. Maintenance and Safety:

Proper maintenance of CNC milling machines is essential to ensure optimal performance and longevity. Regular inspection, lubrication, and calibration of the machine components are necessary. Additionally, following safety protocols and using appropriate personal protective equipment (PPE) is crucial to prevent accidents and ensure operator safety.

10. What Is Cutting Speed, Feed Rate And Depth Of Cut In CNC Machining?

Read this article to get more details

11. How to Calculate the Cost of CNC Milling?

The cost of CNC milling depends on several key factors such as labor hours, material usage, and processing difficulty. It is difficult to give a specific formula for calculating CNC machining costs, but you can quickly obtain an instant quote through the online CNC machining online manufacturing platform.

Conclusion:

In 2023, CNC milling continues to be a driving force in manufacturing, offering unparalleled precision, efficiency, and adaptability. Its integration with AI, automation, and additive manufacturing opens up new possibilities for innovation and customization. By staying informed about the latest trends and applications, you can leverage CNC milling to enhance your manufacturing processes and stay ahead in today’s competitive market. Embrace CNC milling technology, and unlock a world of endless possibilities in the realm of precision manufacturing.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文