- Author

- 12 January 2026

How to Print PET-CF: A Comprehensive Guide

3D printing with PET-CF (Polyethylene Terephthalate Carbon Fiber) can elevate your projects due to its superior strength, stiffness, and thermal resistance. However, working with PET-CF requires specific considerations to achieve optimal results. This guide will walk you through the steps and tips for successfully printing with PET-CF.

What is PET-CF?

PET-CF is a composite material made by infusing carbon fibers into PET (Polyethylene Terephthalate) filament. This combination results in a material that is:

– Stronger and stiffer than standard PET, it has a tensile strength of 78Mpa

– Heat resistant 150℃, making it suitable for high-temperature applications.

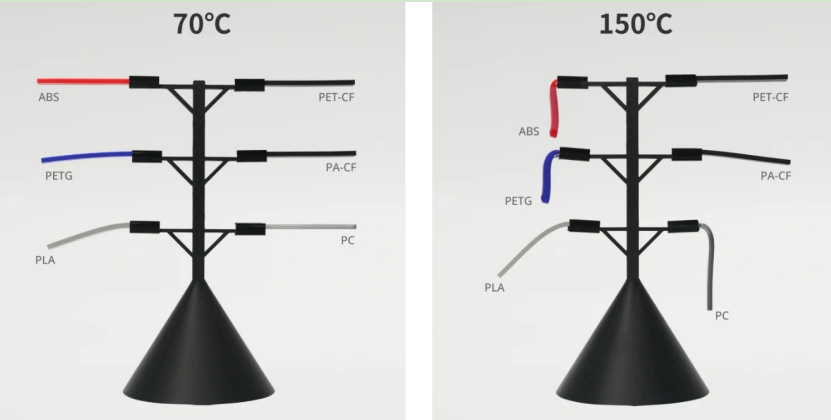

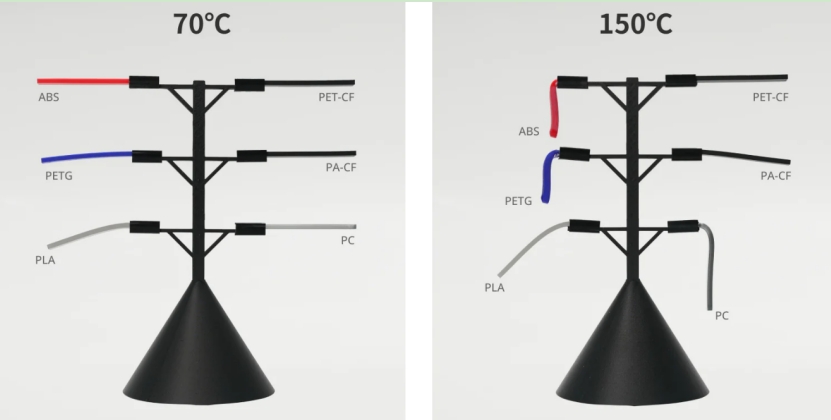

- Specimen size (L*W*H): 95*10*4 mm³

• Test conditions: Specimens were put in an oven at 70 °C and 150 °C respectively for 0.5 hour.

• As a crystalline material, PLA will significantly deform only after the temperature exceeds its melting point (around 155°C).

• Image Source: Bambulab

– Lightweight, with improved structural integrity due to the carbon fibers.

How to Prepare Your 3D Printer for PET-CF?

- Printer Compatibility:

– Ensure your 3D printer has a hardened steel nozzle. Carbon fibers are abrasive and can wear down standard brass nozzles quickly.

– A heated bed is essential, ideally one that can reach temperatures up to 110°C.

- Nozzle Size:

– Use a nozzle size of 0.6mm or larger to prevent clogging. PET-CF can have small carbon fiber fragments that may clog smaller nozzles.

- Extruder Type:

– A direct drive extruder is preferable over a Bowden setup, as it provides better control over the filament.

Printing Settings

1. Temperature:

– Extruder Temperature: Set between 240°C and 260°C. Start at a lower temperature and gradually increase if the filament does not extrude smoothly.

– Bed Temperature: Set between 100°C and 110°C. Use a bed adhesive like PEI or Kapton tape or PVA glue to ensure good adhesion.

2. Print Speed:

– Print at a moderate speed, around 60-90 mm/s. PET-CF requires slower speeds for better layer adhesion and surface finish.

3. Layer Height:

– A layer height of 0.25mm is ideal for balancing detail and strength.

4. Cooling:

– Enable part cooling fans but keep them at a low setting (around 20-30%) to avoid warping.

Preparing the Filament

1. Dry the Filament:

– PET-CF is hygroscopic, meaning it absorbs moisture from the air. Dry the filament in a filament dryer at 70°C for 4-6 hours before printing.

2. Storage:

– Store PET-CF in a sealed container with desiccant packets to keep it dry when not in use.

Printing Tips

1. First Layer:

– Ensure your first layer is well-calibrated. A good first layer adhesion is crucial for the success of the print. Adjust the bed leveling and Z-offset as necessary.

2. Adhesion:

– Use a wider brim( double layers if possible) or raft to improve bed adhesion and prevent warping, especially for larger prints.

3. Support Structures:

– PET-CF can be challenging to remove supports from, so use a minimal support structure or a dual extrusion setup with a soluble support material like PVA.

4. Post-Processing:

– PET-CF prints can be sanded or machined to achieve a smooth finish. Be cautious of the carbon fibers, as they can create fine dust that should not be inhaled.

Troubleshooting Common Issues

- Nozzle Clogs:

– If you experience nozzle clogs, increase the print temperature slightly or use a larger nozzle.

- Warping:

– Warping can be minimized by ensuring the bed is properly heated and using bed adhesives or an enclosure to maintain a consistent temperature.

- Stringing:

– Reduce stringing by adjusting retraction settings. Increase retraction distance or speed incrementally to find the optimal settings.

- Layer Delamination:

– If layers are not adhering well, increase the print temperature or slow down the print speed for better layer bonding.

Conclusion

Printing with PET-CF can be challenging but rewarding, offering high-strength and high-heat resistance parts. By following the proper printer setup, filament preparation, and printing techniques outlined in this guide, you can achieve excellent results with this advanced material. Happy printing!

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文