Every year, IN3DTEC will share the latest report on 3D printing through customer feedback, market research and previous orders

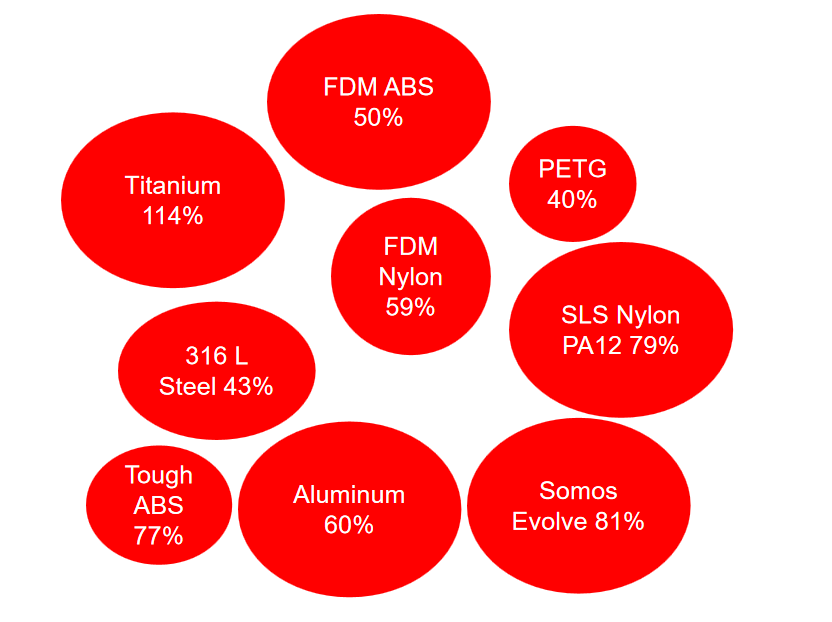

The below image Materials with a noticeable increase in demand in 2022.

This article facilitates customers’ choice by making some simple introductions to these materials

FDM ABS

Key Benefits

Functional, High stability and impact strength, Complaint to European Toy Safty Norm EN 71-3

Ideal applications

-General-purpose applications

-Housing, Cases

-Electronics

-Low-cost prototyping

Weakness

-Visible line on the surface

-Limited dimensional accuracy

Color

White, Black, Red, Blue, Yellow, Grey, Green…

Surface finish

As printed, Sanding, Painting

FDM PETG

Key benefits

Waterproof, Outdoor application, Skin contact safety

Ideal applications

-Outdoor products

-Waterproof products

-Housing & casings

-Consumer products

Color

White, Black, Red, Blue, Yellow, Grey, Green…

Surface finish

As printed, Sanding, Painting

Material Data Sheet>>

FDM nYLON

Key benefits

High-temperature resistance, High friction resistance, Excellent, chemical resistance

Ideal applications

-Automotive, Bike, Boat

-Robotics, drones

-Jigs & fixtures

-Tooling

Weakness

Visible lines on the surface

Color

Black…

Surface finish

As printed, Sanding, Painting

sLS nYLON

Key benefits

High-temperature resistance, High friction resistance, Excellent, chemical resistance

Ideal applications

-Automotive, Bike, Boat

-Robotics, drones

-Jigs & fixtures

-Tooling

Weakness

Visible lines on the surface

Color

Black, White

Surface finish

As printed, Vapor Smoothing, Painting

Aluminum

Key benefits

It offers good strength, hardness and dynamic properties, and is therefore also used for parts subjects to high loads.

Ideal applications

-General-purpose applications

-Aerospace

-Automotive

-Transportation

-Consumer products

-Applications that require a combination of good thermal properties and low weight

316L Steel

Key benefits

This kind of stainless steel is characterized by having good corrosion resistance and evidence that there are no leachable substances in cytotoxic concentrations.

Ideal applications

-Lifestyle/Consumer, e.g. watches, jewelry, spectacle frames, decorations

-Automotive/Industrial, e.g. non-corroding common material, food, and chemical plants

-Aerospace/Turbine industry

TiTanium

Key benefits

Ti64 has a chemical composition corresponding to ASTM F1472 and ASTM F2924. It is a well-known light alloy, characterized by having excellent mechanical properties and corrosion resistance combined with a low specific weight

Ideal applications

– General-purpose applications

-Medical

-Aerospace

-Transportation

-Industries need high mechanical properties and chemical resistance

Tough ABS

Key benefits

SLA Tough ABS is High printing accuracy, smooth surface, detail expression, dimensional stability, strong chemical resistance, high-precision products, and products used in high-humidity environments.

Ideal applications

– General-purpose applications

-Housing & Casing

-Prototypes

Key benefits

Somos Evolve 128 is a durable stereolithography material that produces accurate, high-detailed parts and has been designed for easy finishing. It has a look and feels that is almost indistinguishable from finished traditional thermoplastics, making it is perfect for building parts and prototypes for functional testing applications – resulting in time, money and material savings during product development.

Somos Evolve 128 is an excellent material for aerospace,

automotive, medical, consumer products, and electronics.

Upload your file to our online 3d printing store, and see the price within seconds >>