- Author

- 12 January 2026

Revolutionizing Manufacturing: Unveiling the Top Chinese Metal 3D Printing companies

Welcome to our blog, where we embark on an exciting journey through the realm of manufacturing revolution. In this series, we will dive deep into the world of Chinese metal 3D printing companies, unveiling the trailblazers at the forefront of this transformative industry. With their cutting-edge technologies and relentless pursuit of innovation, these companies have reshaped the landscape of manufacturing, unlocking new possibilities and pushing the boundaries of what is achievable. Join us as we explore the top Chinese metal 3D printing companies, their groundbreaking advancements, and the impact they are making on industries worldwide. Get ready to witness the future of manufacturing unfold before your eyes.

BLT: Advanced Metal Powder Forming 3D Printing Equipment Manufacturer

Founded in 2011, BLT is a metal 3D printing equipment manufacturer located in Xi’an, China. The founding team consists of university professors, and with their technological advantages, BLT has grown to become one of the largest metal equipment company in China. The company invests significant resources into exploring new materials, printing techniques, and software solutions to enhance the capabilities of their 3D printers. Through collaborations with universities, research institutions, and industry partners, BLT actively contributes to the advancement and innovation of 3D printing technologies.

IN3DTEC: One-Stop Station For Prototyping & Production Services.

IN3DTEC was established in 2014 and is headquartered in Shanghai, China. The team members consist of product engineers and enthusiasts with a passion for technology.

Initially, the company focused on metal 3D printing service and gradually introduced advanced equipment.

As of 2022, IN3DTEC has accumulated more than 300 industrial-grade devices, providing a wide range of capabilities, including industrial 3D printing, CNC machining, injection molding, prototyping, sheet metal fabrication, and more. Its strong expertise in surface treatment of components has propelled it to become a leading service manufacturer in China.

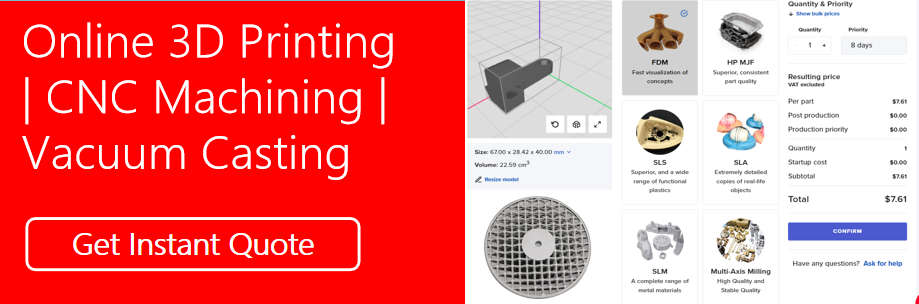

In 2022, the company launched an Instant Quoting System for 3D Printing, CNC Machining, Vacuum Casting, enabling users to obtain instant online quotes and processing in a matter of seconds. The platform system and digitalized management of the manufacturing process have gained favor among many users.

Overall, IN3DTEC is recognized for its expertise in providing innovative and high-quality manufacturing solutions, leveraging advanced technologies to meet the demands of various industries.

Farsoon: Empowering Innovation With Professional Powder Bed Fusion 3D Printers

Founded in 2009, is a Chinese manufacturer and supplier of industrial level polymer and metal Laser Powder Bed Fusion (LPBF) systems. With the established multi-disciplinary team in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. Farsoon is at the forefront of technological advancements in the additive manufacturing industry. The company’s portfolio includes a range of innovative 3D printers, materials, and software solutions. Their printers utilize various technologies, such as Selective Laser Sintering (SLS) and Metal Laser Melting (MLM), to deliver high-precision, high-quality prints. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. Farsoon was founded with the vision of creating an innovation-based company that brings truly open industrial additive systems and value-added solutions to the global market.

Zrapid: Edicating to Industrial 3D Printing equipment, software, material.

Founded in 2018, Zrapid is Chinese company founded by Dr. Zhou Hongzhi, and their core technical staff has 18 years of 3D Print research experience. ZRapid has independently researched and developed full set of 3D Printing Data Preparation Softwares and 3D Printing Equipment Control Systems. ZRapid own full range of independent intellectual property rights Industrial 3D Printer product chain: SLA 3D Printers, SLM 3D Printers, FMS 3D Printers. And the Printing materials include Resin / Metal / Nylon / Coated Sand etc. ZRapid Tech is the technical support unit of 3D Print Engineering Technology Research Center in Jiangsu Province. Based on international advanced additive manufacturing technology, ZRapid commit to meet the market demand at home and abroad as the guide, and to promote the development of China’s high-quality additive manufacturing industry.

HBD Additive Manufacturing: Laser Powder Bed Fusion The machine manufacturer and developer.

Founded in 2007, HBD is one of the leading LPBF (laser powder bed fusion) technology developers and additive machine manufacturers, located in Guangdong and Shanghai, China with certification by SGS-CE, ISO9001, AS9100D and more than 200 patented technologies, and over 30 invention patents serving Aerospace, Dental, Orthopedics, Mold & Die, Automotive, Oil & Gas, Education & Research etc. Since its establishment, the company has launched various metal equipment with different printing sizes. It can achieve a molding size of 460x460x1200mm.

Xi’an Sailong: Electron Beam Melting(SEBM) Systems

Founded in 2013, Sailong is a high-tech enterprise held by Northwest Institute for Non-ferrous Metal Research. It is specialized in R&D, production, marketing and technical services of Selective Electron Beam Melting (SEBM) technologies and systems, Plasma Rotating Electrode Process (PREP) technologies and systems, and 3D printed complex metal components. Sailong has successively undertaken more than 40 major national and provincial science and technology projects, accumulated hundreds of authorized patents and participated in the formulation and revision of more than 30 national and industry standards. Sailong upholds the enterprise spirit of “Learning, Innovation, Concentration and Efficiency” and forges ahead relentlessly with the goal of building an international brand of metal 3D printing cutting-edge technologies and high-end systems.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文