VaporFuse Surfacing an enhanced post-treatment for your 3D parts

With the constant growth of Additive Manufacturing and its fields of application, the demand for 3D-printed parts is also increasing.

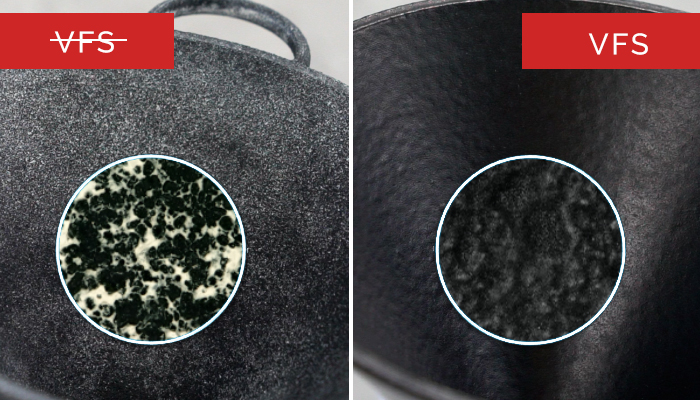

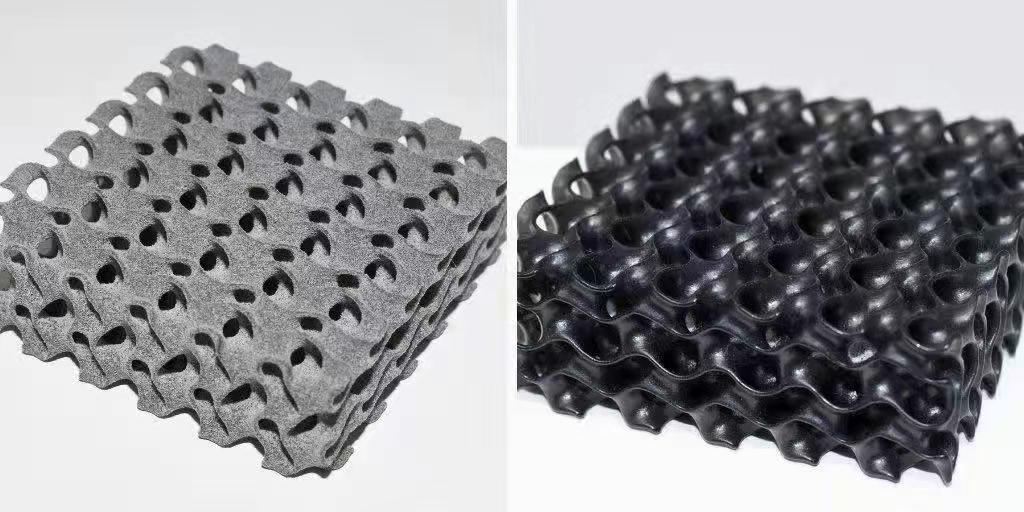

Today, market-ready products manufactured with Powder Bed Fusion technologies such as Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF) must meet both aesthetic and functional requirements. These requirements can vary depending on the product, industry, and application. Since Powder Bed Fusion technologies work layer by layer, the outcome is parted with rough surfaces compared to conventional manufacturing methods. Good post-processing helps to change these part properties.

While for example, tumbling as an abrasive method for 3D-printed parts is usually counterproductive because the material is removed.

Vaporfuse surfacing achieves smooth parts without compromising the part’s geometry or mechanical properties. The surface imperfections are erased from parts with no line of sight issues and effectively seal even complex geometries with internal cavities.

The process of Vaporfuse surfacing

First, The 3D Prints are suspended in the processing chamber and exposed to a controlled amount of solvent vapor. The vapor condenses on the parts, interacting with the polymers at the surface and causing the surface to re-flow.

After a time, the machine heats back up, causing the solvent to re-vaporize, and then it is extracted from the parts and the processing chamber. The parts are then thoroughly dried in the processing chamber, leaving behind just a newly smoothed surface.

The enhanced properties of vaporfuse surfacing

VaporFuse Surfacing is a green industrial technology that delivers sealed and smooth surfaces with improved airtightness, bacteria protection, and part strength. During the process, the surface roughness is reduced to a minimum. The technology is suitable for finishing parts made with laser sintering (SLS), HP Multi Jet Fusion(MJF), and other technologies such as (FDM). It is compatible with many materials, from tough PA12 to TPU and other soft materials.

So what are the advantages of Vapor smoothing?

Sealed surfaces: roughness is reduced by up to over 80%, both inside and outside. It results in a better flow of water and air in each piece.

Productive spray painting: VaporFuse replaces the priming step and reduces the time and material required down to a third.

Improved airtightness: Parts with a skinny layer thickness become airtight due to VaporFuse, allowing more design freedom and using less manufacturing material.

Reduced friction: Using VaporFuse Surfacing technology can create smooth parts with over 40% less friction, less abrasion, and no chafing effect.

Improved stability: Printed parts with greater flexibility & reduced embrittlement.

Bacteria inhibition: VFS protects surfaces from bacterial growth, making them easier to clean and disinfect. That leads to washable surfaces, resistance to chemical and oily products, and avoiding residues after cleaning the parts.

A green industrial solution

Until now, chemical smoothing was mainly linked to aggressive chemicals that can generate toxic waste, having a harmful impact on the ecological footprint, but also might be potentially damaging for operators, as they were CMR solvents (carcinogens, mutagens, and reprotoxic). Therefore, the invention of a sustainable post-processing solution was necessary.

The solvent for vaporfuse surfacing is a non-CMR solvent, eco-friendly.

In addition, the system does not produce waste due to a completely closed circuit with the integrated recovery of the solvent. The system can operate autonomously 24 hours a day, seven days a week, and is applicable for Industry 4.0.

If you are interested in vaporfusing surfacing, please get in touch with IN3DTEC. We warmly welcome your question or inquiry!