What's the difference between slS and mJF 3D Printing

The main difference between SLS and MJF 3D Printing is the cost then followed by the productivity, surface smoothness, surface treatment, types of materials, ect.

We believe readers who read this article already had a basic explanation for both SLS and MJF 3D Printing technologies.

In addition, this article will mention several common SLS 3D printers in the market.

Let’s talk about their differences from several Points that users are most concerned about,

- Manufacturing Cost

- Surface smoothness

- Surface treatment

- Types of materials

- Food-safe and Skin safe

- Mechanical performance

Manufacturing Cost difference

If we want to understand this, it is best to start by analyzing the equipment and material costs

So how much is HP Multi Jet 3D Printers?

$270,000-$430,000

So how much is per Kg of HP Muti Jet 3D printing powder?

Although we use HP printers to print every day, due to confidentiality principles, we cannot share. Unfortunately, its price cannot be found online. However, you can imagine that HP’s 3D printers can only be bound to HP or its recommended BASF materials. In view of its progressiveness technology, it is not difficult to understand that HP printing is more expensive than SLS.

How much are SLS 3D Printers?

There are many brands of 3D printers commonly found in the market, distinguished by desktop and industrial-grade models, and there are probably the following.

There are several of popular SLS 3D Printers in the market,

Ranking is not sequential, just for writing convenience. If you are not very satisfied with whether the printer is desktop or industrial-grade type, please feel free to pass info@in3dtec Contact us to provide corrective suggestions.

Desktop ones

Formlabs Fuse 1, Sintratec Kit, Sinterit Lisa, Sharebot, etc

$ 5,999 to $27,999.

Industrial-grade SLS 3D Printers

EOS, Prodways, 3D Systems, Farsoon, Zrapid

$158,730 to $303,000

What is the cost of SLS plastic powder?

Starting from $43 till $200 per Kg.

Ads: IN3DTEC can also directly sell SLS 3D printing powder for your printers with a very cheap price.

In summary, SLS printing is quite cheaper than MJF 3D Printing. Almost 40-50% off.

Surface smoothness difference

The surface smoothness of HP’s 3D printed parts is MUCH better than that of most SLS printing equipment. However, with the gradual maturity of SLS 3D printing technology, this gap is gradually decreasing.

One point that needs to be mentioned. The orientation and speed of printing will also affect the surface smoothness. Muti Jet 3D printing also has several optional speeds, such as fast mode, balanced mode… The most direct manifestation is that the quality is different. So selecting a professional 3D Printing Service provider is very important.

What’s more, surface treatments, such as Vaporfuse smoothing, graphite blasting can improve the smoothness.

Types of materials difference

SLS 3D Printing: PA6+GF, PEEK (By EOS), PA12, PA11, PP, TPU(90A)

MJF 3D Printing : PA12, PA11, TPU, PA12+GF, PP

Food-safe and Skin safe

In SLS 3D Printing, EOS PA2200 is a food-safe material.

The materials of PA12 and PA11 in MJF 3D Printing are Skin safe.

Most of other SLS 3D Printing materials don’t have data showing it is food or skin safe.

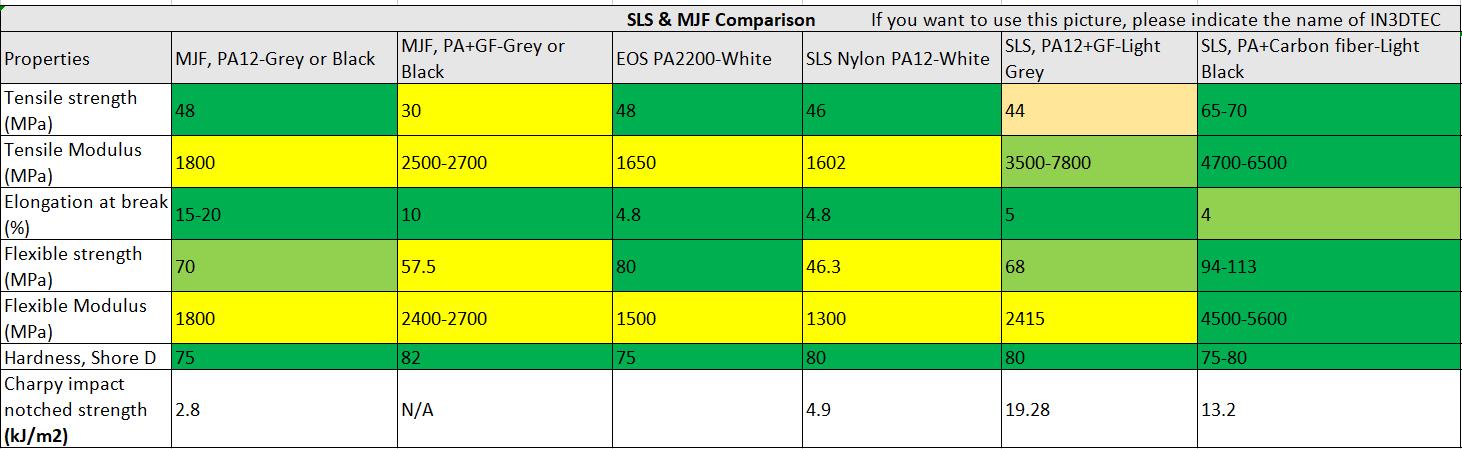

Mechanical performance difference

In order to facilitate understanding, we have made a table for you.

We hope this article can help you. If you need professional industrial-grade 3D printing services, welcome to visit our website and quickly manufacture your samples through online 3D printing services.