- Author

- 12 January 2026

What to Consider When Selecting a Metal 3D Printing Service

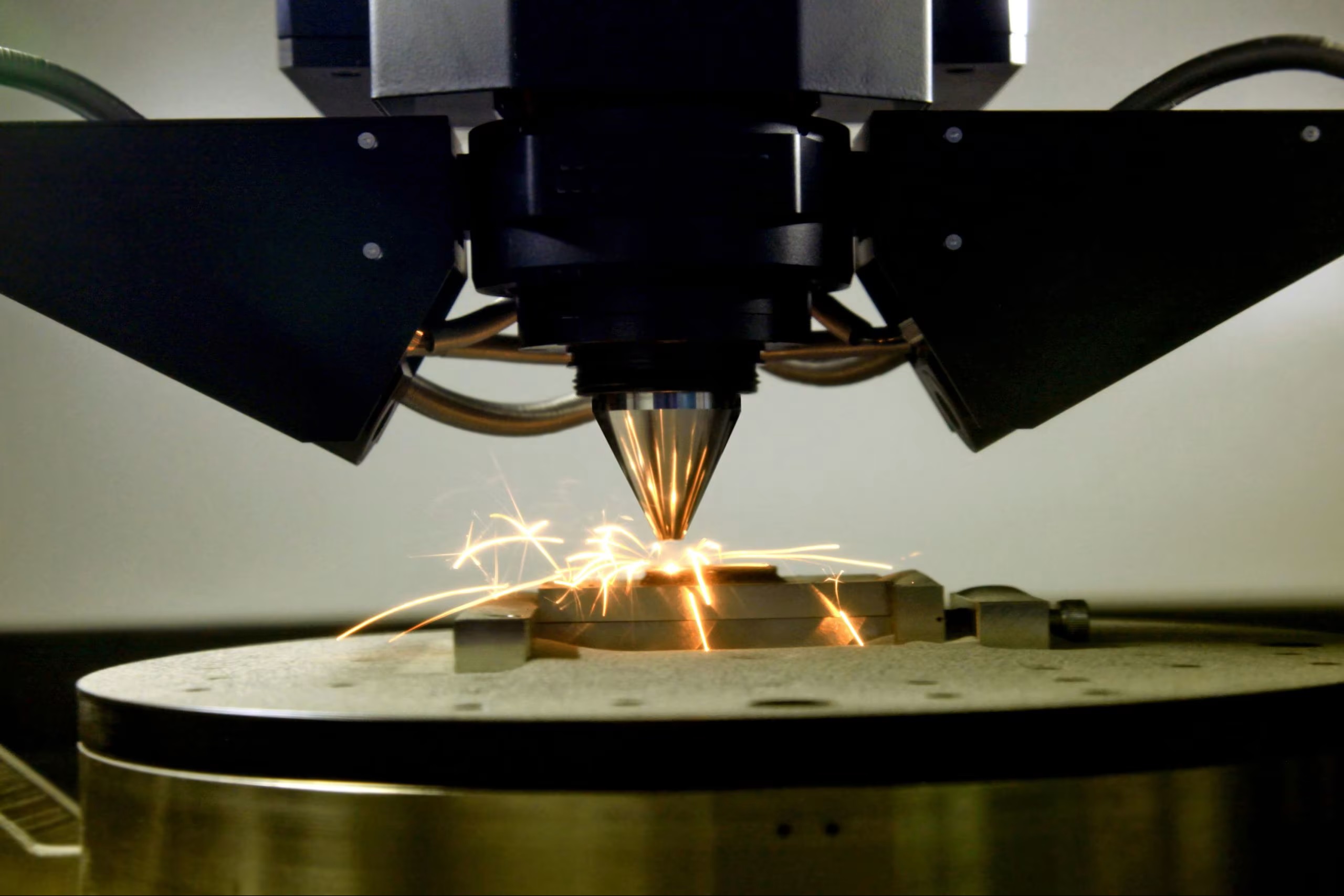

Metal 3D printing, also known as additive manufacturing, is revolutionizing industries by enabling the production of complex and precise metal parts. Whether you’re creating functional prototypes, custom tools, or end-use components, choosing the right metal 3D printing service is critical to achieving high-quality results.

With various service providers and technologies available, how do you make the best choice? In this blog, we’ll explore the key factors to consider when selecting a metal 3D printing service.

1. Material Availability

The choice of material significantly impacts the performance and durability of your part. Common materials used in metal 3D printing include:

Stainless Steel: Corrosion-resistant and ideal for mechanical parts.In 3D printing, common stainless steel grades include 316L and 17-4 PH.

Aluminum: Lightweight and excellent for aerospace or automotive applications.With IN3DTEC, both AlSi10Mg and AL6061 are available, the last one also support anodizing surface finish.

Titanium(TC4, Grade 5): Strong and biocompatible, suitable for medical and aerospace industries.

Inconel 718&625 are available: Heat-resistant for applications in extreme environments like gas turbines.

Tool Steels: For high-strength tooling and manufacturing components.

Ensure the service provider offers the specific material you need for your project. Additionally, verify the material’s certification, especially for industries with strict quality standards like aerospace and healthcare. More technical information, please click here to download the TDS of each material.

2. Printing Technology

Different metal 3D printing technologies offer distinct advantages and limitations:

- Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM): High precision and density, ideal for complex geometries and functional parts.

- Binder Jetting: Cost-effective for large-scale production but may require post-processing for strength.

- Electron Beam Melting (EBM): Excellent for high-performance materials like titanium, commonly used in medical and aerospace fields.

- Metal Fused Deposition Modeling (FDM): A budget-friendly option for prototypes or non-critical applications.

Choose a service that uses the technology best suited to your application’s requirements.

More article: Different types of Metal 3D Printing technology

3. Part Size and Build Volume

Metal 3D printers have specific build volumes, which dictate the maximum size of parts they can produce. If your part exceeds the build volume, it may need to be printed in sections and assembled later, which could affect strength and aesthetics.

Verify that the service provider’s equipment can accommodate your design dimensions and inquire about their approach to larger or complex builds.

At IN3DTEC, the Max Build volume for metals is 500x500x500mm.

Upload your CAD files to the online quoting system to get an instant quote.

4. Quality Assurance and Certifications

Quality is paramount in metal 3D printing, particularly for applications in industries like aerospace, medical, and automotive. Look for 3D Printing service providers with inspection processes, such penetration testing, X-ray CT scanning or nondestructive testing, 3D Scanning & data matching to ensure part integrity.

5. Surface Finish and Post-Processing Options

Metal 3D printed parts often require post-processing to achieve the desired surface finish, strength, or functionality. Common post-processing techniques include:

- Heat Treatment: Enhances material properties like strength and ductility.

- CNC Machining: Improves dimensional accuracy and surface finish.

- Polishing: Achieves a smooth, aesthetic finish.

- Coatings: Adds corrosion resistance or improves wear resistance.

Ensure the service provider offers the post-processing options your project requires and understands how these processes integrate with their 3D printing workflow.

6. Lead Time and Production Speed

Time is often a critical factor in manufacturing projects. Ask about the 3D Printing service provider’s lead times, including both printing and post-processing phases.

- Prototyping: Some providers offer rapid turnaround for prototypes.

- Production: Ensure they can handle the scale of your production needs without delays.

A reliable service provider will have streamlined processes and clear communication to meet your deadlines.

7. Cost and Budget

Metal 3D printing can be costly, so it’s crucial to find the right balance between cost and quality. IN3DTEC is a leading provider of metal 3D printing services, offering high-quality prints at very competitive prices, with a fast turnaround time of as little as three days.

8. Design Expertise and Support

Metal 3D printing often requires design adjustments for manufacturability. Look for a service provider with experienced engineers who can:

- Optimize your design for additive manufacturing (e.g., reducing support structures, improving thermal flow).

- Provide feedback to ensure your part meets its functional requirements.

A collaborative approach can save time and resources while ensuring a successful outcome. Learn how to design parts for metals.

9. Reputation and Reviews

Research the service provider’s track record:

- Look for customer testimonials and case studies.

- Ask for samples of their previous work to evaluate quality.

- Consider their experience in your specific industry.

A reputable provider will have a proven history of delivering high-quality parts and excellent customer service.

10. Scalability

If you anticipate scaling production in the future, ensure the provider can handle increased demand without compromising quality or lead time. Services with multiple printers and robust workflows are better equipped for scalability. IN3DTEC has more than 80 units of industrial metal 3D Printers in-house.

Conclusion

Selecting the right metal 3D printing service is crucial for ensuring the success of your project. By considering factors such as material options, technology, quality assurance, and cost, you can make an informed decision that meets your technical and business needs.

Metal 3D printing is a powerful tool for producing innovative, high-performance parts. With the right service provider, you’ll unlock the full potential of this transformative technology.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文