What is Vacuum Casting?

Vacuum casting vs 3D Printing Vs Injection Molding vs injection Molding

This article aims to help users understand the process and advantages of vacuum casting, then choose more suitable materials when developing new products. As usual, the article is divided into the following sections.

Table of contents

- What is vacuum casting?

- How does vacuum casting work?

- Vaccum Casting cost, Materials, Geometric complexity, accuracy, roughness

- Vacuum casting vs CNC Machining vs 3D Printing Vs Injection Molding

- Key factors you should know when selecting Vaccum Casting

Vaccum Casting Simplify explained

Vacuum casting service is a copying technique used for the production of small series of functional & high-quality end-use plastic parts. It is a casting process for plastics using a vacuum to draw the liquid material into the mold, then put it into an oven for getting the final solid parts.

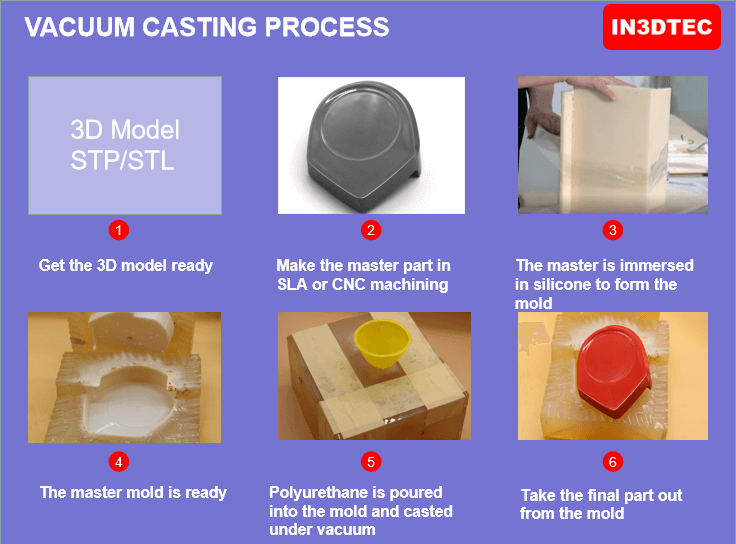

How vacuum casting works?

Vacuum casting is a copying technique used for the production of small series of functional & high-quality end-use plastic parts. It is a casting process for plastics using a vacuum to draw the liquid material into the mold, then put it into an oven for getting the final solid parts.

vacuum casting materials

Vacuum casting service is mainly used for producing plastics, the materials including ABS, PC, PP, NYLON, and TPU/PU/Rubber.

Please click HERE to view the technical data-sheet of these materials.

vacuum casting Cost,Geometric complexity,accuracy,roughness

Complexity

Vacuum casting service has advantages in creating parts with high geometric complexity. Its is not sensitive to the complexity of the structure, Allow designers to have unlimited spatial imagination.

Complexity, From high to low

3D Printing > Vacuum casting > CNC Machining > =Injection Molding

Accuracy

ABS, PC, PP, NYLON with a tolerance of +/-0.1mm

TPU/PU/RUBBER with a tolerance of +/-0.3mm

Roughness or Smoothness

From high to low

Injection Molding >= Vacuum casting > CNC Machining > 3D Printing

Cost

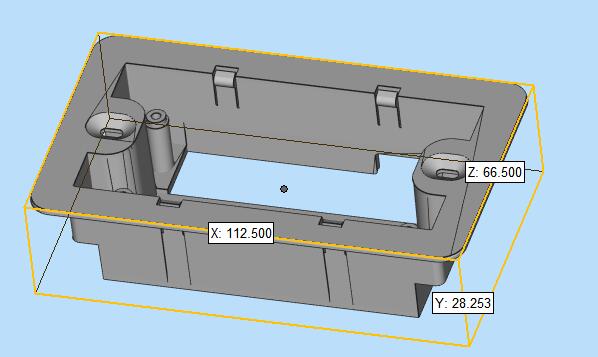

Let’s take the part below/image an example,

Material: ABS

Quantity: 20 pieces

Cost from cheap to expensive

3D Printing (USD8/piece)<Vacuum Casting(USD26/piece) < CNC Machining(USD40/piece)

Vacuum Casting Vs CNC Machining vs 3D Printing Vs Injection Molding

When we talk about vacuum casting, we usually compare it with injection molding. So, let’s distinguish the difference between them first.

Vacuum Casting Vs Injection Molding

Let’s take the mobile phone case as an example, the mold of the vacuum casting service is only tens of dollars, while injection molding costs thousands of dollars. On the other hand, the production fee of vacuum casting service is tens of dollars per unit, while injection molding only costs 1 or 2 dollars.

In brief, vacuum casting service has a lower front-end cost and a higher unit price, while injection molding requires a higher front-end cost, but the unit price is significantly lower。

Vacuum Casting Vs 3D Printing

Compared with 3D Printing(3DP), what’s the advantage of vacuum casting? Base on the same material, vacuum casting service has higher smoothness, durable, and accuracy, and it has not limitation to the color as well.

Vacuum Casting Vs CNC Machining

It is difficult to say which one is better, but if we consider the complexity of the prototype, production efficiency, and cost, vacuum casting will have more advantages. While the CNC has more material options, the material performance is better.

Being able to make soft materials quickly is one of the biggest advantages of vacuum casting. It supports materials from Shore 30A to Shore 95A, from Shore 10D to Shore 90D, in any customized Pantone No.

In conclusion, vacuum casting service is not in conflict with and can’t replace other technologies, Instead, it is a supplement way, providing more flexible solutions for manufacturing.

Key factors when selecting vacuum casting

3D Printing(3DP), CNC Machining(CNC), Vacuum Casting( VC), Injection Molding(IM)

High Geometric structure: 3DP & VC are betterDimensional accuracy: CNC & VC are better

Mechanical properties in all 3 dimensions: CNC & VC are better.

Lead time: CNC with 6-8 days, VC with 6-8 days, IM with 35 days, 3DP as fast as one day,

Cost: Complex geometry or lightweight parts, 3DP and VC have more advantages.

Quantity: 3DP, CNC, and VC are suitable for low-volume parts, IM is more suitable for large volume parts.