- Author

- 25 February 2026

Whitepaper of mold surface texture for injection molding

All plastic molders understand that the surface texture of the mold cavity and core will transfer a texture to the corresponding molded part. But even experienced molders can be unclear about the exact technical language used to describe these finishes, how they’re created by toolmakers and how to measure them correctly in a production environment.

What is Plastic Mold Texture?

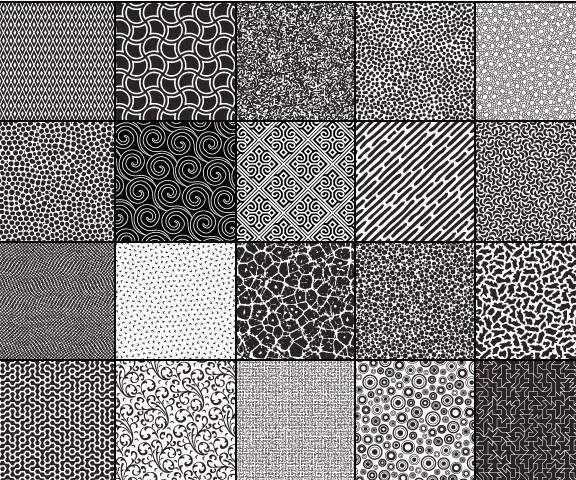

Texture also refers to graining, a process of creating patterns. It’s for the improvement of plastic mold. The mold texturing process is a very cheap way of making complex patterns on plastic parts. Various factors involved in the precise creation of injection mold textures. In this process, we can produce a variety of patterns on the surface of molded plastic parts. Through chemiosmosis, we create patterns on the metal surfaces. Some types of graining in plastic are:

Satin Patterns

Geometric Pattern

Wood Grain

HN3D

Leather Pattern

HANDS

Stripes & Images

Sand Pattern

How To Measure Surface Texture in Injection Molding, And What Are SPI Mould Finish Standards?

You must be familiar with the technical language. Molders use for measuring and describing the surface finish chart. How do toolmakers measure them in the production industry? Tools make surface texture in the manufacturing process. If you want to get the desired surface texture, it’s essential to know. How to texture plastic, and how can you measure it?

Mold texturing companies must abide by the standards. Standards created by plastic industry association(PIA). PIA is a regulatory and trade organization. It helps and supports all plastic chains all over the world. They have set standards to measure the specific kinds of finishes. These standards check the finishing quality and cosmetic quality of plastics. These standards are also called SPI comparators due to their former name. Plastic mold makers use these comparators for the measuring of finishes. According to the PIA classification system, there are four grades: A, B, C, and D.

Group A: finishes made with diamond buffing place in group A.

Group B: finishes made with grit sandpaper relate to group B.

Group C: finishes made with grit sanding stones specified in group C.

Group D: finishes made with pressure blasting are in the D category. Molders use aluminum

Do Various Finish Surfaces Play A Role In Production Cost?

When we choose a surface texture, many factors involved in its production. Time and efforts for surface texturing play a significant role in parts cost. If you choose a high surface texture from the plastic texture chart. It may be more costly and time-consuming. As more time and effort may need for its manufacturing.

Category A :

This category is for the highest standard grades. Finishes made with diamond buffing belong to this category. Molders apply a diamond buffing paste. Then polishes the surface with the help of a rotary tool. This process will complete in a non-linear pattern and a random. It reflects the light without the sign of a transparent texture. Category A finishes are shiny, glossy, and smooth. These finishes are much costly, and we make visors, optical parts, and mirrors. Category A further divided into three levels.

Category B :

They are semi-gloss finishes and made with sandpaper. Category B finishes have enough concealing properties for manufacturing flaws. Such as marks of machining and toolings. They are cheaper than category A. It requires 600 grit for B-1, 400 for grit B-2 and 320 grit required for B-3. Molders apply finishes in the back and forth motion. Thus during the production of the pattern, it makes linear scratches on the molded parts.

Category C :

In this category, finishes with grit standing stone classify. The grit of the stone range is from 600 to 320. Finishes create a flat and rough surface. The reason is their aggressiveness during the cutting process. We use this process to erase molding marks and tooling and give the plastic a matte finish look.

Category D :

Blasting with glass beads and sand produces rough finishes. The random nature of the spray creates a non-directional and uniform finish. This level performs for dull and flat finishes.

Finishes made with EDM

In addition to the four categories, there are similar results that can be produced using electrical discharge machining (EDM) or spark erosion. We use both approaches depending on the features and the type of metal being processed. Both processes are measured according to the PLASTICS standards.

Expressing the shine of your part with gloss

We advise clients, at minimum, to specify not only a PLASTICS surface finish but also gloss. Gloss is defined as the reflectance of a surface compared to a polished black glass standard.

We use a simple gloss meter. This device bounces a light off the surface of a sample at different angles depending on the Ra value being tested. The measurement values are called gloss units (GUs). The black glass standard is rated as 100, so measured gloss units from a target part are compared to this reading. From these gloss readings, it’s then possible to describe a surface as high-gloss, semi-gloss, matte or flat.

Obviously surface textures and finishes are designed to achieve cosmetic and functional effects on the part. Rougher textures provide better grip, and can also be used to hide minor molding defects like weld lines. But note that rougher surface textures are harder to release from the mold, so draft angles usually must be increased accordingly. That’s why it’s a good idea for toolmakers and product designers to work closely together in the early stages of product development, and why they need to speak a common language of surface finish terminology. In IN3DTEC, we will provide comprehensive service for your parts from the initial stage of design to final products.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文