Whitepaper of SLM (selective laser melting)

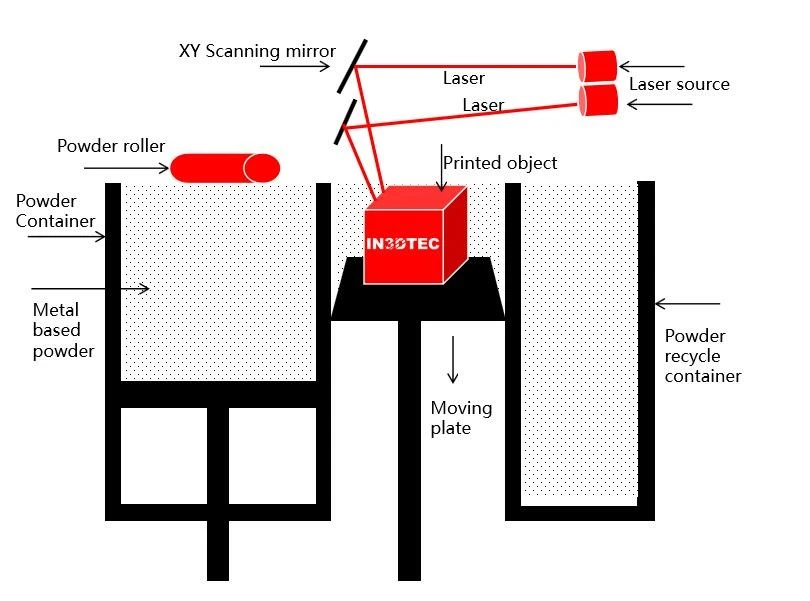

How does SLM work?

|

|

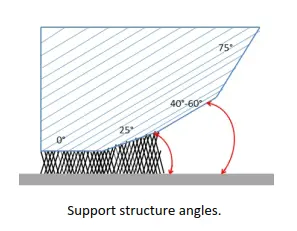

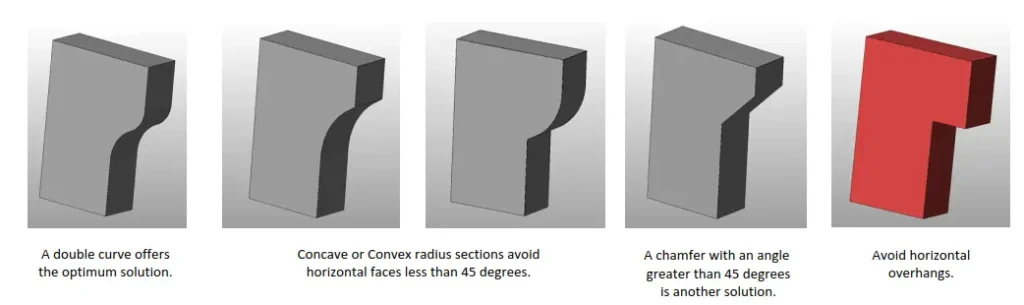

Managing Overhangs.

Support structures can be eliminated from overhanging features with the use of curves or chamfers:

Inner channels and holes

The ideal shape for inner channels is influenced by the need to avoid support structures. Tear-Drop shapes are ideal as much they minimize overhang and are self-supporting.

Holes. Post build drilling

Where holes are required in your design, design them undersized so they can be drilled as part of the post build processing. Drilling assures the accuracy and roundness of critical hole features.

Reduce volume

Lattice like structures used for strength while avoiding solid volume

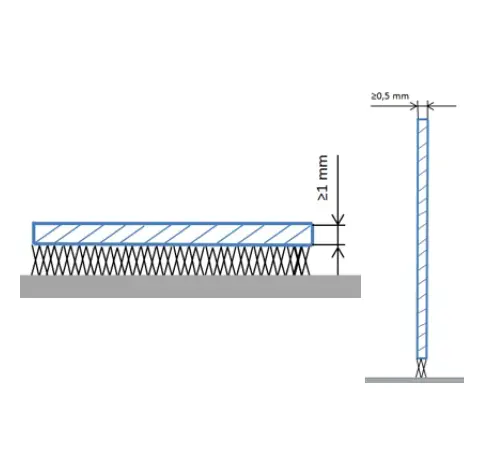

Wall Thicknesses

Generally wall thicknesses of ≥ 0.5mm are possible but is dependent on material and part geometry. Horizontal walls should be ≥ 1mm. The thermal conductivity of your selected alloy influences the minimum wall thickness achievable.

Comparison between 3D printing and CNC machining

The only technology worth comparing with traditional CNC machining is metal 3D printing. The most popular techniques currently employed are SLS (Selective Laser Sintering) and SLM (Selective Laser Melting). These techniques use a form of metal powder that is placed layer by layer. Then a laser traces out the pattern of the part cross section at that layer height, fusing the powder together. See video above. Thereafter, another thin powder layer is placed and the process repeats.

Let’s compare some of the key factors of CNC machining and 3D printing:

1. Cost

Cost is usually the most important factor when deciding on how a part is to be manufactured. The costs are generally comparable when looking at prototypes. However, the per unit cost for 3D printing is always the same, so it quickly loses out to CNC when the quantity of parts increases. CNC parts become considerably cheaper as the number of units increase making this method ideal for larger production runs.

2. Speed

3D printing is significantly slower than CNC machining which gets faster with each new development. There is no way 3D printing can currently compete with the speed of a CNC machine. This then directly affects the cost for the customer.

3. Set-up Time

The set-up time for each of these machines is also significant. With CNC machining, the CAD part needs to be prepared for the machine. This requires the expertise of a CAM (Computer Aided Manufacturing) expert to set up the required tools and tool paths. With AM, the CAD part is imported into a slicer program which is like CAM, but requires a lot less expertise from the operator as the software does all the work. The operator just decides on the optimal orientation of the part on the build platform.

Once the gCode is sent to the 3D printer, the operator is no longer needed until the part is complete. Upon completion, the operator cleans all the unused powder from the part. In a normal CNC machine, the operator might have to turn the part over and restart the machine so that the underside can be machined.

4. Design Flexibility

When it comes to design flexibility, AM has a sizeable advantage as many features that CNC machines struggle with are trivial on an AM machine. Some examples are undercuts, multi axis features such as holes that are off the primary axis, and hollow parts with a lightweight honeycomb internal structure. AM may produce prototype parts that look amazing and futuristic, but the reality is that these prototypes cannot be cost effectively mass produced, and therefore can only serve industries that require complex and low production volume parts. This is often the case within the aerospace industry.

5. Tolerances

If accurate parts are needed, then CNC machining is the only option, as they can produce parts with extremely high tolerances. The general tolerance of a CNC machine is about 0.1mm for quick prototypes, and can be pushed to 0.005mm for high precision work. A 3D printer is typically capable of a 0.1mm tolerance.

Furthermore, if a polished surface finish is necessary then AM parts will not be suitable as they have a relatively rough finish due to the powder particles that are used to make up the parts. On less expensive machines the individual layers can be seen, further ruining the appearance. AM parts often need post-processing, and a small amount of CNC machining is typically required to bring near-netshape parts into tight tolerances for applications that require them. Whereas, CNC machines can produce high quality finishes with very low surface roughness values.

Conclusion

As with CNC machining when it was at its infancy, 3D printing will continue to become more relevant as a manufacturing technique. Advances in AM techniques are being made almost daily. Costs will continue to drop, and speeds will increase. There are currently technologies being developed that can print large batches of parts by using a metal infused resin that is then placed in a furnace that turns them into usable components.

However, CNC machines will continue to dominate the manufacturing scene for the foreseeable future, and despite its few disadvantages when compared to AM, it is a mature, widespread technology that you can bank on. When it comes to a cost effective, volume manufacture with tight tolerances and a good surface finish, then CNC is still the best solution hands down.