Whitepaper: SLS (Selective Laser Sintering) Explained

How does SLS work?

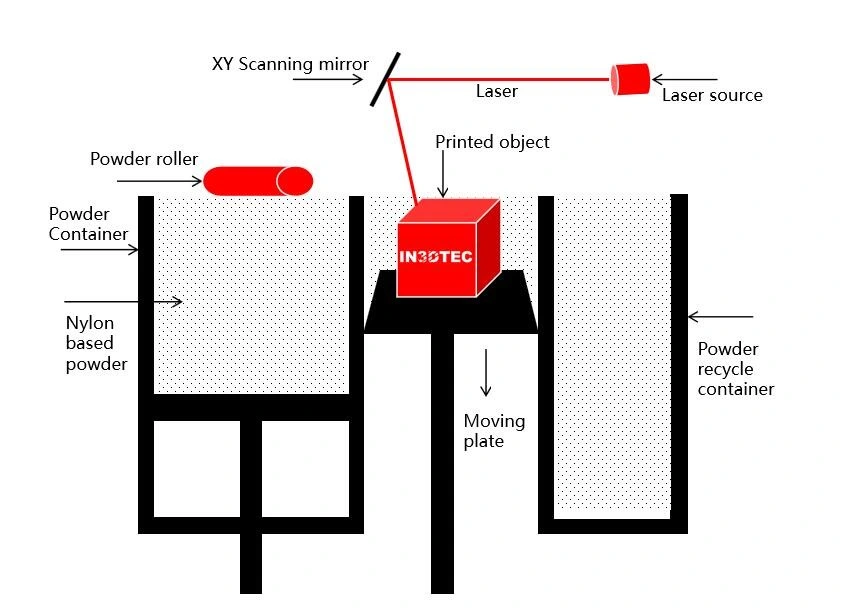

Powder Bed Fusion is a 3D printing process where a thermal energy source will selectively induce fusion between powder particles inside a build area to create a solid object.

Many Powder Bed Fusion devices also employ a mechanism for applying and smoothing powder simultaneous to an object being fabricated, so that the final item is encased and supported in unused powder.

- Types of 3D Printing Technology: Selective Laser Sintering (SLS)

- Materials: Thermoplastic powder (Nylon 6, Nylon 11, Nylon 12)

- Dimensional Accuracy: ±0.3% (lower limit ±0.3 mm)

- Common Applications: Functional parts; Complex ducting (hollow designs); Low run part production

- Strengths: Functional parts, excellent mechanical properties; Complex geometries

- Weaknesses: Longer lead times; Higher cost than FFF for functional applications

Materials for SLS 3D Printing

Selective laser sintering is a popular technology among 3D printing processes as it can be used with a wide range of materials. The most currently used materials can be classified in two categories:

Rigid materials: such as PA12, PA12 Glass-Filles, PA6

Flexible materials: such as TPU

The Nylon PA12

The Nylon PA12 (plastic) objects printed are created from a fine polyamide powder, more commonly known as plastic. Nylon PA12 (Plastic) is great for both experienced professionals and beginning designers because of its high precision and low cost. The good mechanical properties of this nylon material will be for more advanced additive manufacturing projects and can even substitute injection molding plastics. Thanks to its low concentration of amides, it has small moisture absorption, which implies a good resistance to chemicals.

PA12 Glass-Filles

Objects printed in Nylon 3200 Glass-filled (glass-filled nylon) are made from a mix of polyamide powder and glass fibers. The surface of this 3D printing material is white and slightly porous. Our Nylon 3200 Glass-filled (glass-filled polyamide) is more durable and resistant than Nylon PA12.

Using this engineering thermoplastic for 3D printing gives you great freedom in your designs – allowing for both complex and inclosed volumes. The material is great for technical parts that need resistance and loads. The surface of Nylon 3200 Glass-filled (glass-filled nylon) is not as accurate as Nylon PA12 but it will fit the requirements of technical parts. Glass-filled nylon has some good mechanical properties.

PA6

PA6 is one of the most popular engineering polymers for series applications. PA6 is characterized by high strength and rigidity, uncompromising tightness and excellent thermal performance properties. Compared to conventional injection-molded PA6, PA6 shows improved performance with less moisture absorption.

The combination of high heat resistance with excellent mechanical performance makes the material the right choice for demanding technical applications in harsh environments.

TPU

The Selective Laser Sintering TPU (or SLS TPU) is a Thermoplastic Polyurethane material. If you are looking for a resistant, flexible, and rubbery material, this TPU is the perfect option.

With a good resilience after deformation and a high UV stability, this SLS TPU offers numerous advantages for your projects requiring an elastomeric material. By creating an interesting structural design, parts can be 3D printed for various applications, from automotive to footwear industries. The material also offers good hydrolysis resistance, great shock absorption, and a smooth white surface.

Post treatment

Standard finish

This is the default finish for SLS. Parts are removed from the build chamber and all powder is removed from the part with compressed air. The surface is then also cleaned via plastic bead blasting to remove any un-sintered powder sticking to the surface. This finish is inherently rough, similar to a medium grit sandpaper (satin-like matte finish that is slightly grainy).

Media tumbled

For a smoother surface texture, Nylon SLS parts can be polished in media tumblers or vibro machines. A tumbler that contains small ceramic chips that vibrate against the object gradually erode the outer surface down to a polished finish. As a result, this process does have a small effect on part dimensions and results in rounding sharp edges. It is not recommended that parts with fine details and intricate features are tumbled.

Dyeing

The fastest most cost-effective method to color SLS prints is via a dye process. The porosity of SLS parts makes them ideal for dyeing. The part is immersed in a hot color bath with a large range of colors available. Using a color bath ensures full coverage of all internal and external surface. Typically the dye only penetrates the part down to a depth of around 0.5 mm meaning continued wear to the surface will expose the original powder color.

Spray paint or lacquering

SLS parts are able to be spray painted. SLS parts can also be coated with a lacquer (varnish or clear coat). Via lacquering it is possible to obtain various finishes, such as high gloss or a metallic sheen. Lacquer coatings can improve wear resistance, surface hardness, water tightness and limit marks and smudges on the surface of the part.

Due to the porous nature of SLS it is recommended that 4 – 5 very thin coats are applied to achieve a final finish rather than 1 thick coat. This results in a faster drying time and reduce the likelihood of the paint or lacquer running.

Electroplating

A process for adding metal to the surface of an SLS part is electroplating. Copper, nickel, or a combination of both can be deposited on the surface of parts to increase strength or electrical conductivity in shielding applications. The plastic can be retained as structural support or removed to create thin-walled parts 0.001” to 0.005” (25 to 125 microns) thick. Metal plating thicknesses of over 0.100” are possible on parts with certain geometries.

SLS Fastener Inserts

SLS nylon can be tapped directly for integration of fasteners. When additional strength or more cycles are required, metal inserts can be used. Metal inserts are generally made from brass or stainless steel, and are available in many shapes and sizes.

Design guideline

Like all manufacturing techniques there are several design recommendations that exist to improve the quality, surface finish and functionality of SLS parts. One of the most advantageous characteristics of designing and printing parts using SLS is that there is no need for support structures. The unsintered powder surrounding the part removes the need for support allowing highly complex and intricate designs to be printed.

Wall thickness

The minimum wall thickness to ensure a successful 3D print varies between 0.8 mm (for PA12) up to 2.0 mm (for carbon filled polyamide).

Hole size

All holes should be larger than 1.5 mm diameter.

Escape holes

To save weight (and sometimes costs) SLS parts are printed hollow. To remove unsintered powder after production escape holes must be included. Escape holes must be a minimum of 3.5 mm diameter.

Feature size (pins, protruding features etc.)

A minimum size of 0.8 mm is recommended.

Embossed and engraved details

To ensure small details are visible the following rules apply:

- Minimum depth of engraving 1 mm

- Minimum height of embossing 1 mm

Text

To ensure readability of text the following rules apply:

- Minimum font height of 2 mm (font size 14) suitable for every direction

- Sans serif font is recommended for readability

Tolerances

Typical tolerances for SLS parts are ± 0.3 mm or ± 0.05 mm/mm, whichever is greater.