- Author

- 12 January 2026

10 different types of metal casting process

This article analyzes the forming principles, advantages and disadvantages of 10 common metal casting technologies. Help readers make the best choice faster when choosing metal casting process.

What is metal casting?

Liquid metal is poured into the mold cavity that is suitable for the shape and size of the part, and is cooled and solidified to obtain blanks or parts. It is usually called liquid metal forming or casting.

Casting process: liquid metal → filling → solidification shrinkage → casting

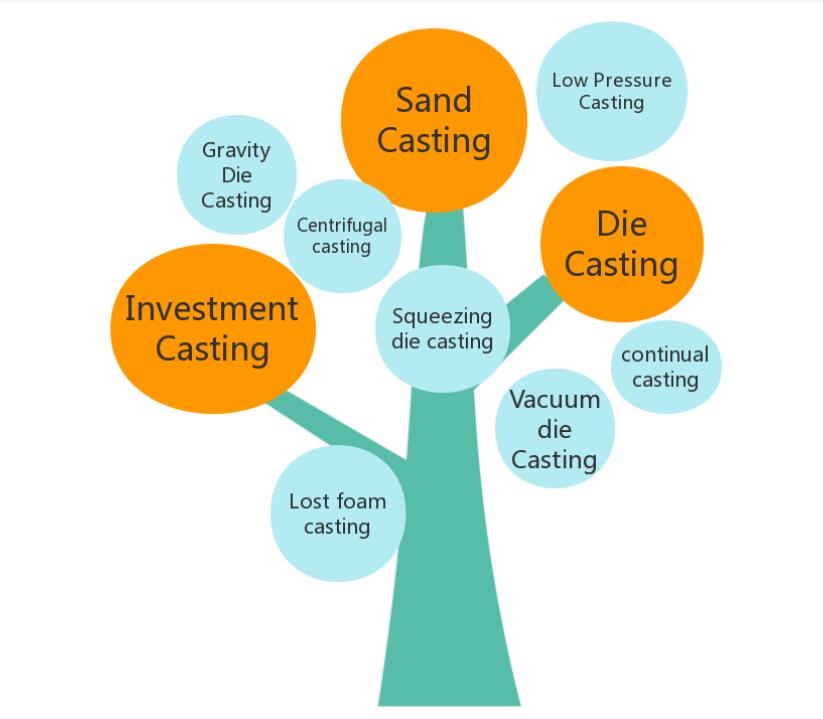

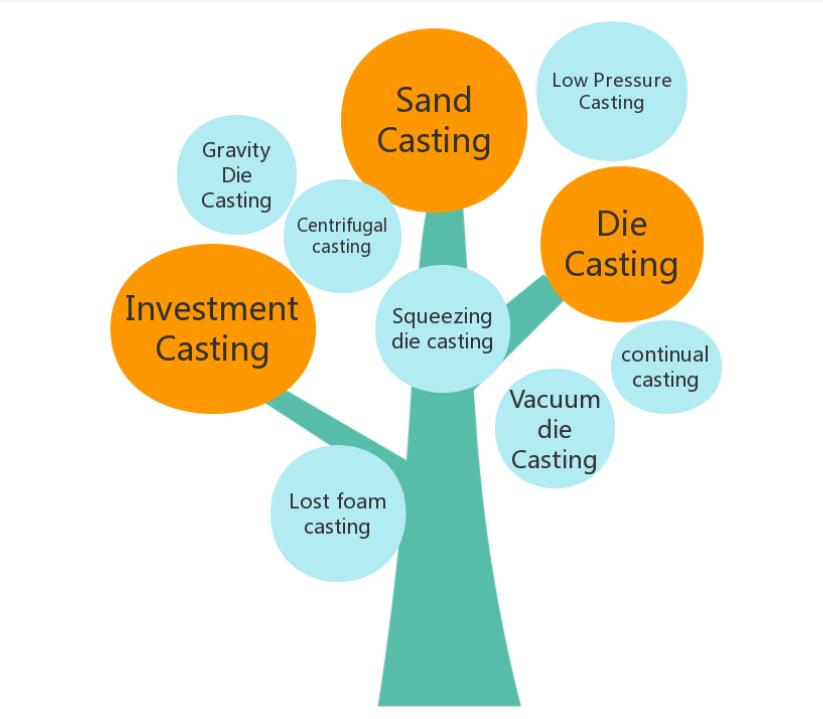

There are ten tyeps of common metal casting process

What are the advantages of Casting process ?

- It can produce parts with arbitrary complex shapes, especially those with complex inner cavity shapes.

- Strong adaptability, unlimited types of alloys, almost unlimited size of castings.

- The source of materials is wide, the waste products can be remelted, and the equipment investment is low.

- High scrap rate, low surface quality and poor working conditions.

Metal Casting Categories

There are 10 different common types of the metal casting process

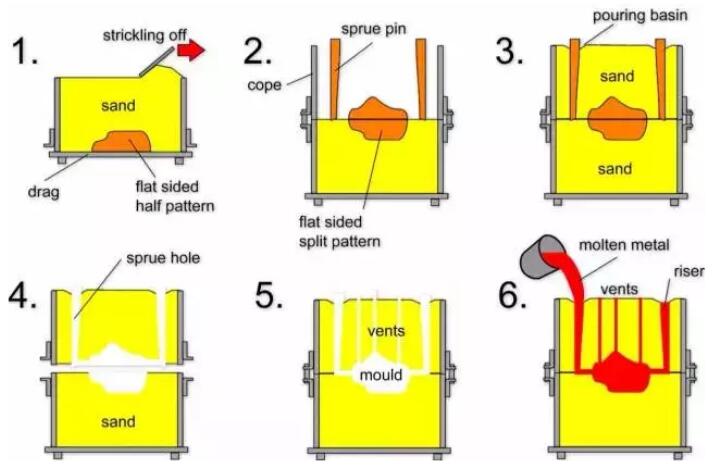

1. Sand Casting

Sand casting: A casting method in which castings are produced in sand molds. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting.

Process flow:

Technical Features:

- It is suitable for making blanks with complex shapes, especially with complex inner cavities;

- Wide adaptability and low cost;

- For some materials with poor plasticity, such as cast iron, sand casting is the only forming process for manufacturing its parts or blanks.

Application: Engine cylinder blocks, cylinder heads, crankshafts, and other castings of automobiles

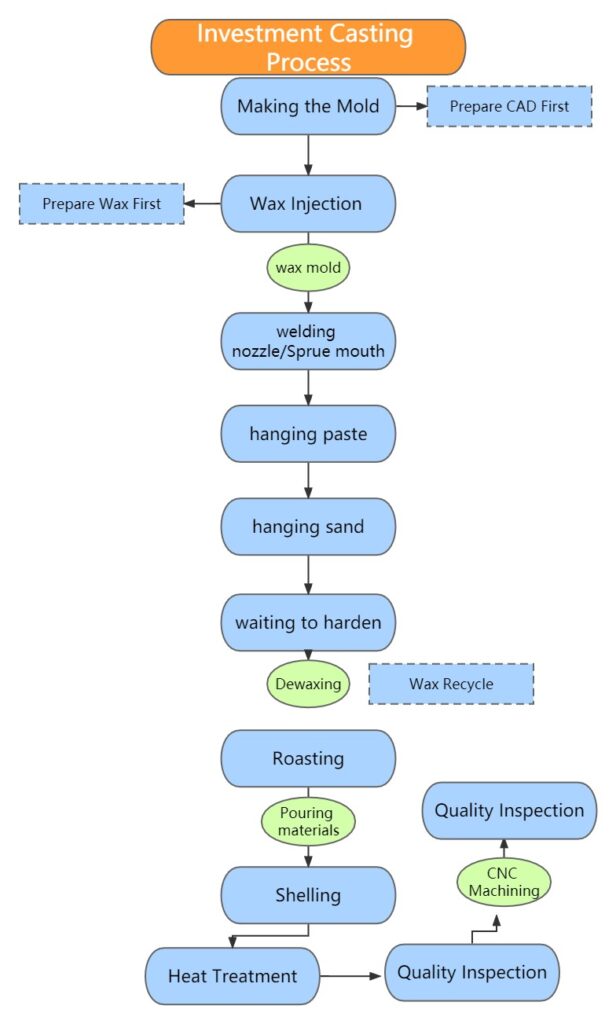

2.Investment casting

Investment casting: usually refers to making a pattern from a fusible material, coating several layers of refractory material on the surface of the pattern to make a shell, and then melting the pattern to discharge the shell, so as to obtain a mold without a parting surface, which is roasted at high temperature The casting scheme that can be filled with sand after pouring. Often referred to as “lost wax casting”.

Advantages:

- High dimensional accuracy and geometric accuracy

- High surface roughness;

- It can cast castings with complex shapes, and the casting alloys are not limited.

Disadvantages: complicated process and high cost

Application: It is suitable for the production of small parts with complex shapes, high precision requirements, or difficult other processing, such as blades of turbine engines, etc.

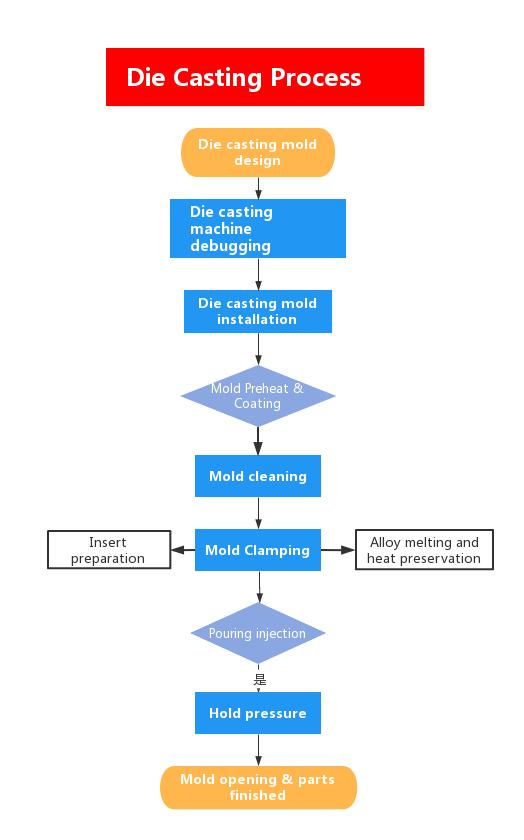

3.Die Casting

Die casting: It uses high pressure to press molten metal into a precision metal mold cavity at high speed, and the molten metal is cooled and solidified under pressure to form a casting.

Advantages:

- During die-casting, the metal liquid bears high pressure and the flow rate is fast

- Good product quality, stable size and good interchangeability;

- The production efficiency is high, and the die-casting mold can be used frequently;

- It is suitable for mass production and has good economic benefits.

Disadvantages:

- Castings are prone to tiny pores and shrinkage.

- Die castings have low plasticity, so it is not suitable to work under impact load and vibration;

- When die-casting high-melting point alloys, the life of the mold is low, which affects the expansion of die-casting production.

Application: Die castings were first used in the automobile industry and the instrument industry, and then gradually expanded to various industries, such as agricultural machinery, machine tool industry, electronics industry, defense industry, computer, medical equipment, clocks, cameras, daily hardware and other industries .

4. Low-Pressure Casting

Low-pressure casting: refers to the method of filling the mold with liquid metal under the action of low pressure (0.02-0.06MPa) and crystallizing under pressure to form castings.

Process flow:

Technical Features:

- The pressure and speed during pouring can be adjusted, so it can be applied to various casting molds (such as metal molds, sand molds, etc.), casting various alloys and castings of various sizes;

- Bottom-injection filling is adopted, and the liquid metal filling is stable without splashing, which can avoid getting involved in gas and scouring the mold wall and core, and improve the pass rate of castings;

- The casting crystallizes under pressure, the casting structure is dense, the outline is clear, the surface is smooth, and the mechanical properties are high, which is especially beneficial for the casting of large and thin-walled parts;

- The feeding riser is omitted, and the metal utilization rate is increased to 90% to 98%;

- Low labor intensity, good working conditions, simple equipment, easy to realize mechanization and automation.

Application: mainly traditional products (cylinder head, wheel hub, cylinder frame, etc.).

5.Centrifugal casting

Centrifugal casting: It is a casting method in which molten metal is poured into a rotating mold, and the mold is filled and solidified under the action of centrifugal force.

Process flow:

Advantage:

- There is almost no metal consumption in the pouring system and riser system, which improves the process yield;

- There is no need for a core when producing hollow castings, so the metal filling ability can be greatly improved when producing long tubular castings;

- The casting has high density, fewer defects such as pores and slag inclusions, and high mechanical properties;

- It is convenient to manufacture composite metal castings such as barrels and sleeves.

Disadvantages:

- There are certain limitations when used to produce special-shaped castings;

- The diameter of the inner hole of the casting is not accurate, the surface of the inner hole is relatively rough, the quality is poor, and the machining allowance is large;

- Castings are prone to specific gravity segregation.

Application:

Centrifugal casting was first used to produce cast pipes. At home and abroad, centrifugal casting technology is used in metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense, automobile and other industries to produce steel, iron and non-ferrous carbon alloy castings. Among them, the production of castings such as centrifugal cast iron pipes, internal combustion engine cylinder liners and shaft sleeves is the most common.

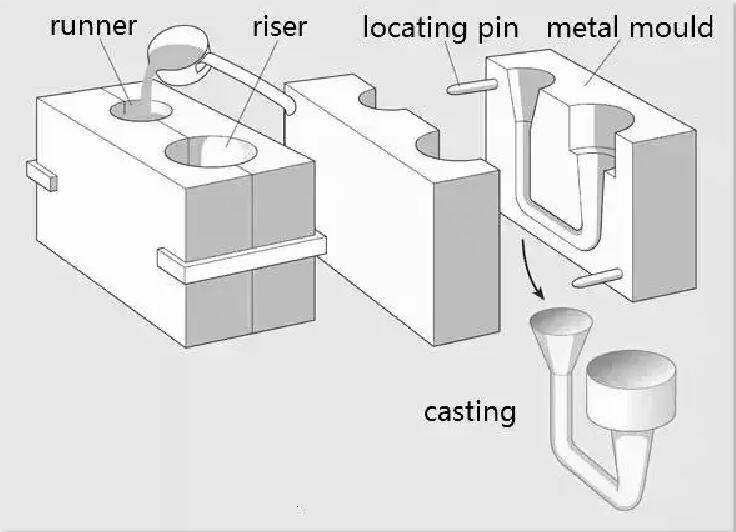

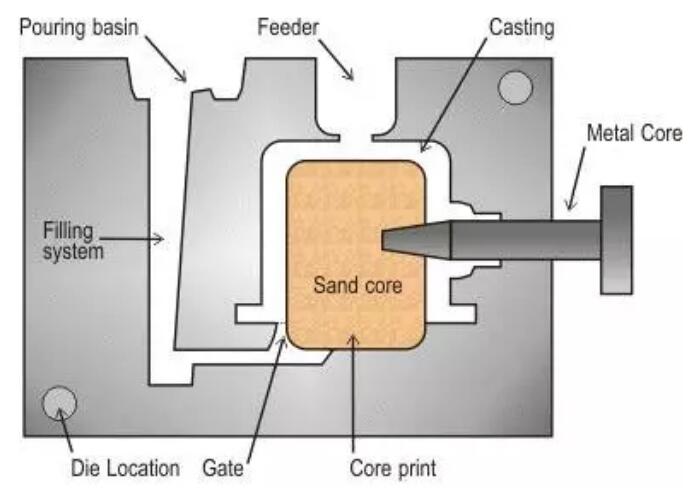

6. Gravity die casting/Metal Mold Casting

Metal mold casting: refers to a molding method in which liquid metal fills a metal mold under the action of gravity and cools and solidifies in the mold to obtain a casting.

Process flow:

Advantages:

- The metal mold’s thermal conductivity and heat capacity are large, the cooling speed is fast, the structure of the casting is dense, and the mechanical properties are about 15% higher than that of the sand casting.

- Castings with high dimensional accuracy and low surface roughness can be obtained, and the quality stability is good.

- Because sand cores are not used or rarely used, the environment is improved, dust and harmful gases are reduced, and the labor intensity is reduced.

Disadvantages:

- The metal mold itself has no air permeability, and certain measures must be taken to export the air in the cavity and the gas generated by the sand core;

- The metal type has no concession, and the casting is prone to cracks when it solidifies;

- The metal mold manufacturing cycle is longer and the cost is higher. Therefore, good economic effects can only be shown when mass-produced in large quantities.

Application:

Metal mold casting is not only suitable for the mass production of non-ferrous alloy castings such as aluminum alloys and magnesium alloys with complex shapes, but also for the production of iron and steel metal castings and ingots.

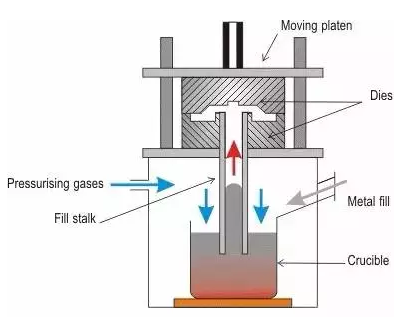

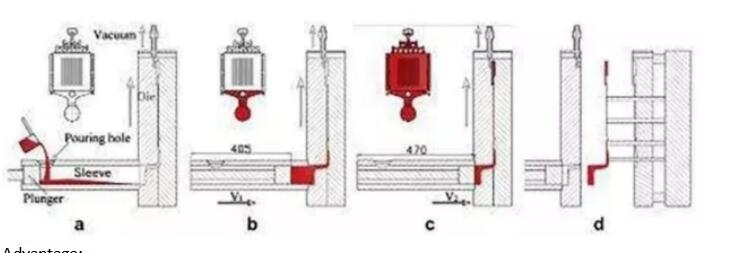

7.Vacuum die casting

Vacuumdie casting: an advanced die-casting process that improves the mechanical properties and surface quality of die-castings by eliminating or significantly reducing the pores and dissolved gases in the die-castings by pumping out the gas in the die-casting mold cavity during the die-casting process.

Process flow:

Advantage:

- Eliminate or reduce the pores inside the die casting, improve the mechanical properties and surface quality of the die casting, and improve the coating performance;

- To reduce the back pressure of the cavity, alloys with lower specific pressure and poor casting performance can be used, and it is possible to die-cast larger castings with small machines;

- The filling condition is improved, and thinner castings can be die-casted.

Disadvantages:

- The mold sealing structure is complicated, and it is difficult to manufacture and install, so the cost is high;

- If the vacuum die-casting method is not properly controlled, the effect will not be very significant.

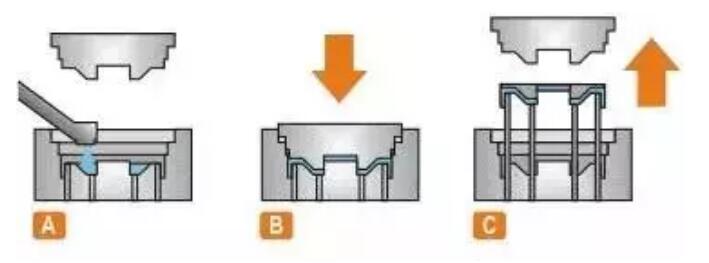

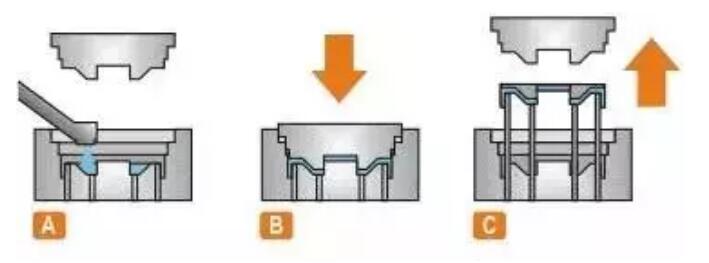

8. Squeezing die casting

Squeeze casting: It is a method of solidifying and flowing forming liquid or semi-solid metal under high pressure to directly obtain workpieces or blanks. It has the advantages of high utilization rate of liquid metal, simplified process and stable quality. It is an energy-saving metal forming technology with potential application prospects.

Process flow:

Direct extrusion casting: spray paint, cast alloy, mold clamping, pressurization, pressure maintaining, pressure relief, mold splitting, blank demoulding, reset;

Indirect extrusion casting: coating, mold clamping, feeding, filling, pressurization, pressure holding, pressure relief, mold parting, blank demoulding, reset.

Technical Features:

- It can eliminate internal defects such as pores, shrinkage cavities and shrinkage porosity;

- Low surface roughness and high dimensional accuracy;

- It can prevent the generation of casting cracks;

- It is easy to realize mechanization and automation.

Application: It can be used to produce various types of alloys, such as aluminum alloy, zinc alloy, copper alloy, ductile iron, etc.

9. Lost Foam Casting

Lost foam casting (also known as solid casting): it is to bond and combine paraffin or foam models similar in size and shape to the castings to form a model cluster. It is a new casting method that the mold is vaporized by pressing down and pouring, and the liquid metal occupies the position of the mold, solidifies and cools to form a casting.

Technical Features:

- The casting has high precision and no sand core, which reduces the processing time;

- No parting surface, flexible design and high degree of freedom;

- Clean production, no pollution;

- Reduce investment and production costs.

Application:

It is suitable for the production of precision castings of various sizes with complex structures. The types of alloys are not limited, and the production batches are not limited. Such as gray cast iron engine case, high manganese steel elbow, etc.

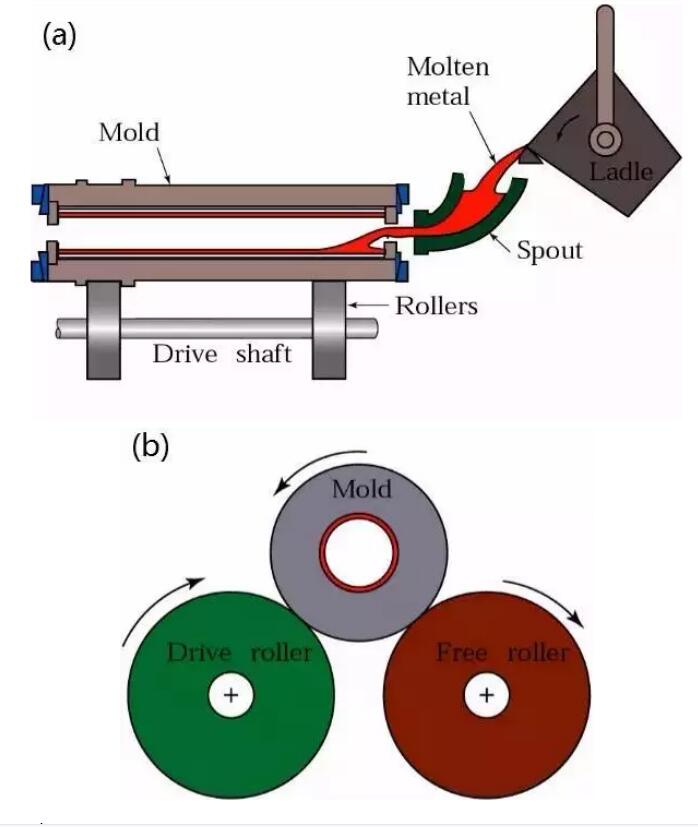

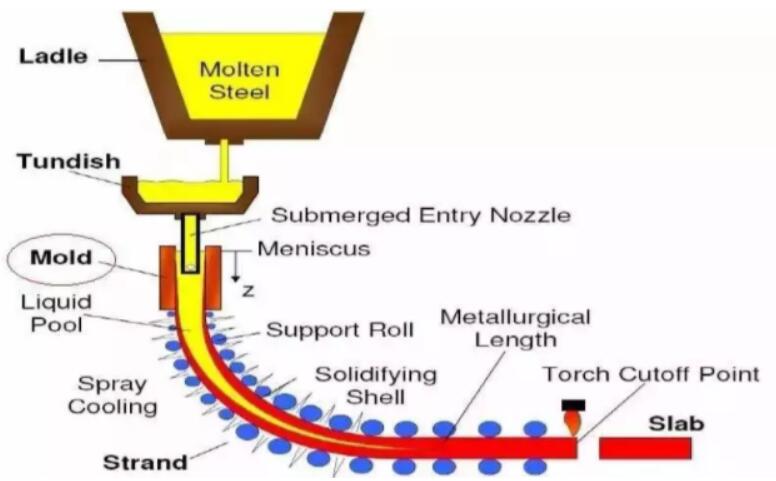

10. Continual Casting

Continuous casting: It is an advanced casting method. Its principle is to continuously pour molten metal into a special metal mold called a crystallizer, and the solidified (crusted) casting is continuously poured from the other side of the crystallizer. Pulled out at one end, it obtains castings of any length or a specific length.

Process flow:

Technical Features:

- Due to the rapid cooling of the metal, the crystallization is dense, the structure is uniform, and the mechanical properties are good;

- Save metal and increase yield;

- The process is simplified, and the modeling and other processes are exempted, thus reducing the labor intensity; the required production area is also greatly reduced;

- Continuous casting production is easy to realize mechanization and automation, and improves production efficiency.

Application:

The continuous casting method can cast steel, iron, copper alloy, aluminum alloy, magnesium alloy and other long castings with constant cross-sectional shapes, such as ingots, slabs, billets, pipes, etc.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文