Transform Real-World Objects into Precise Digital Models with Professional 3D Scanning Services

Our 3D scanning services deliver highly accurate digital models for inspection, reverse engineering, and rapid manufacturing.

What is 3D Scanning?

3D Scanning is the process of capturing real-world objects to digitally recreate their shape and appearance. This technology transforms physical objects into accurate 3D models, which can serve as a foundation for new projects or be used to reconstruct, analyze, and simulate designs.

With our 3D scanning services, we offer the most suitable scanning techniques for your needs, including laser scanning, photogrammetry, and structured light scanning.

Our 3D Scanning Capabilities

High Accuracy: Up to ±0.02 mm precision

Large & Small Parts: From tiny components to objects over 3 m

Fast Turnaround: Scans ready in hours

Versatile Output: STL, STEP, OBJ formats

Surface Detail: Captures textures, curves, and fine features

Why IN3DTEC for Your 3D Scanning Projects

From idea to production, we help you get there faster.

8,000+

– Parts scanned each year.

80+

– Countries we served.

15+

– 8+ Experienced engineers in our scanning team.

Fast Turnaround

– Speed without compromising quality.

Expert Support

– Design optimization & engineering guidance.

Strict Quality Control

– Certified processes, reliable results.

Scalable Production

– We can help you create parts from prototypes to mass production.

Global Service

– Worldwide delivery & logistics support.

Competitive Pricing

– Flexible and cost-effective solutions.

Applications of 3D Scanning

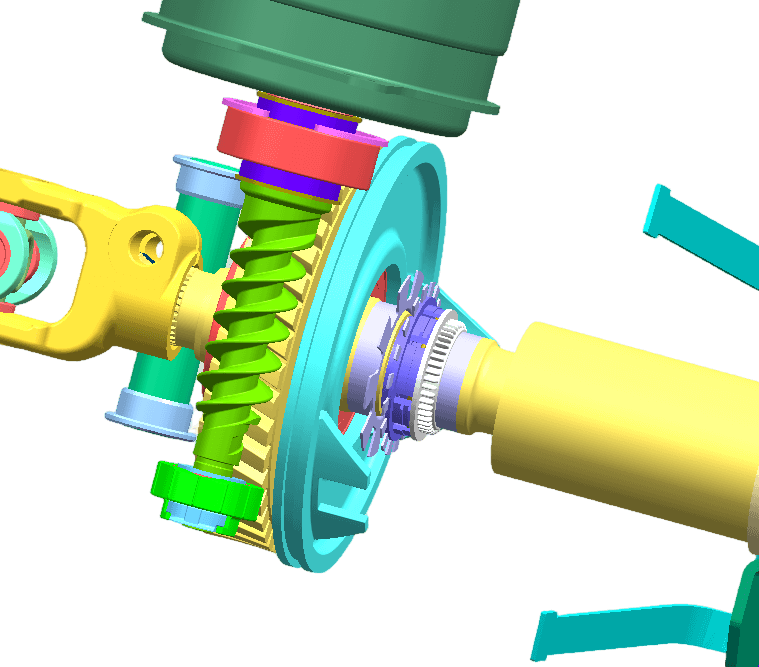

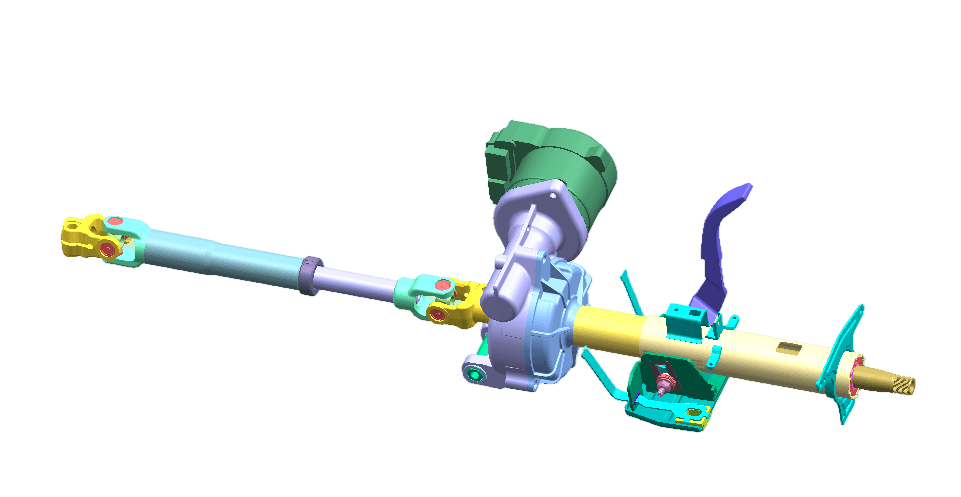

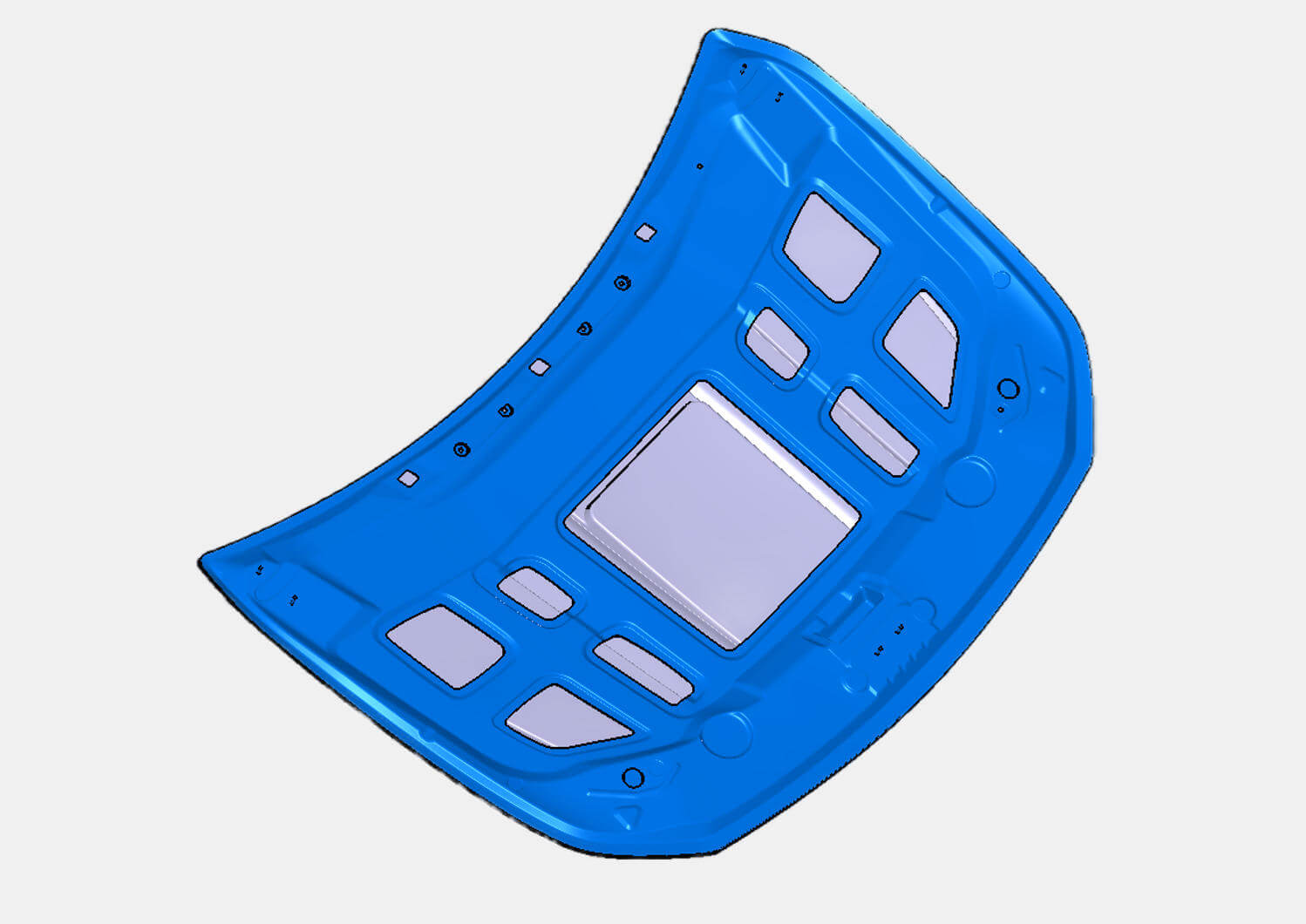

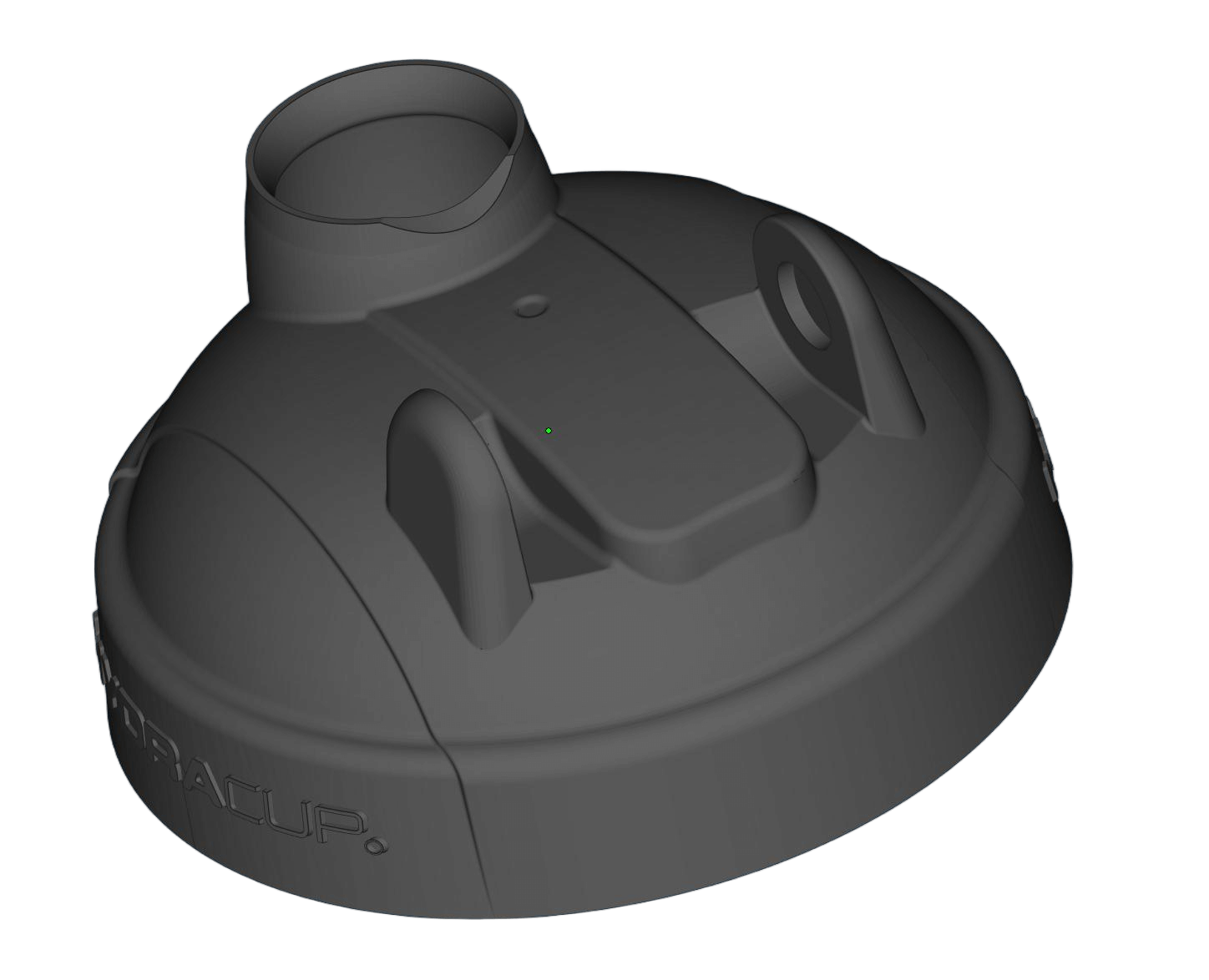

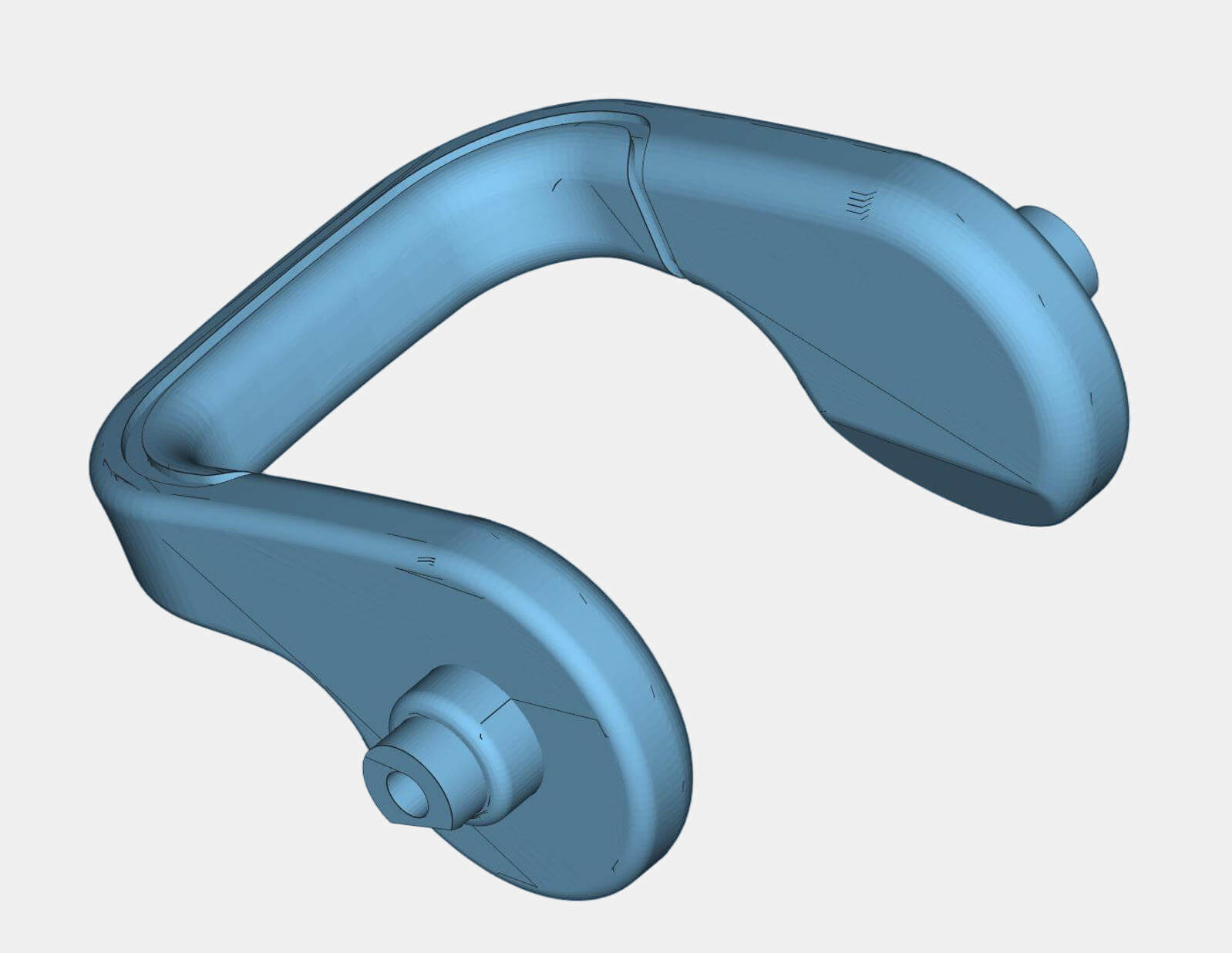

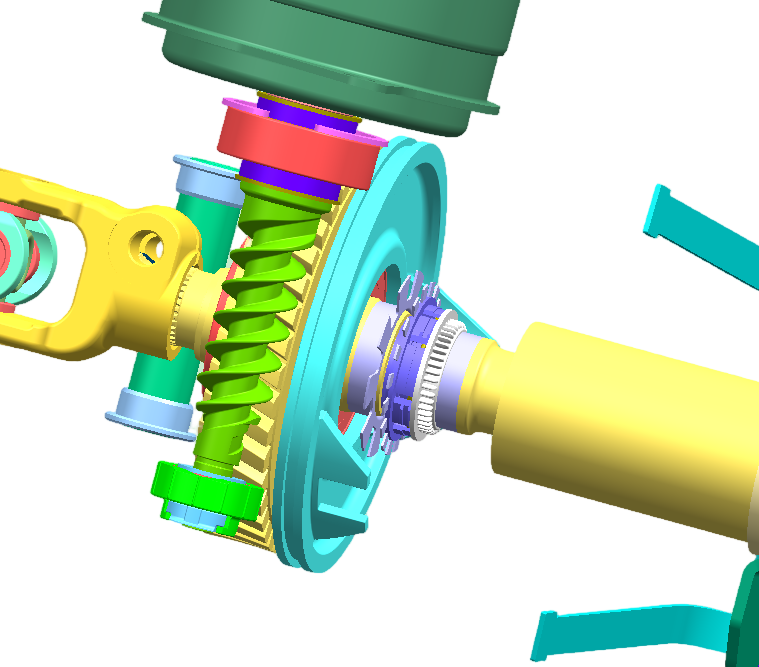

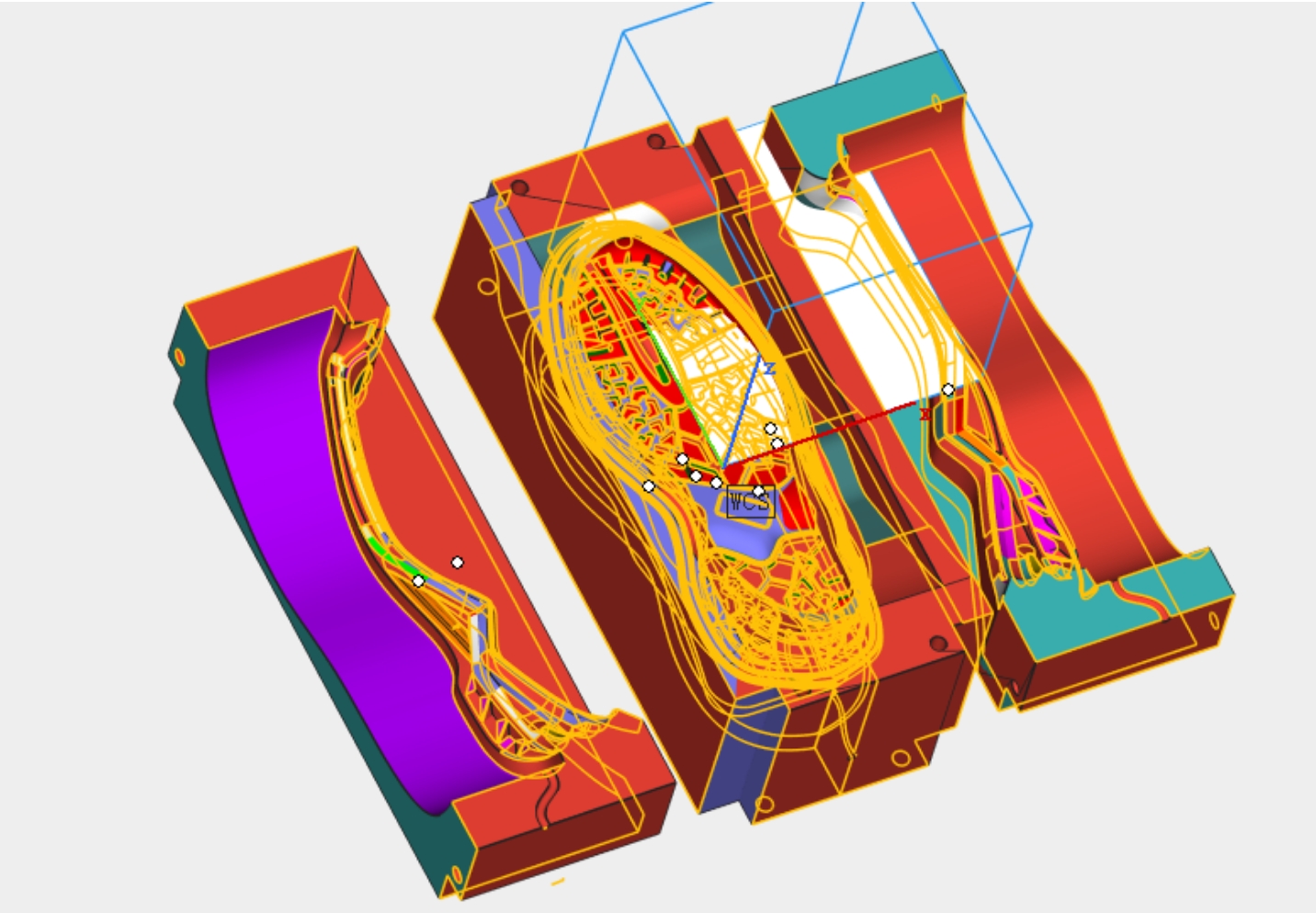

Reverse Engineering – Recreate designs from existing parts

Quality Inspection – Compare parts against CAD data for accuracy

Rapid Prototyping – Speed up design iteration and prototyping

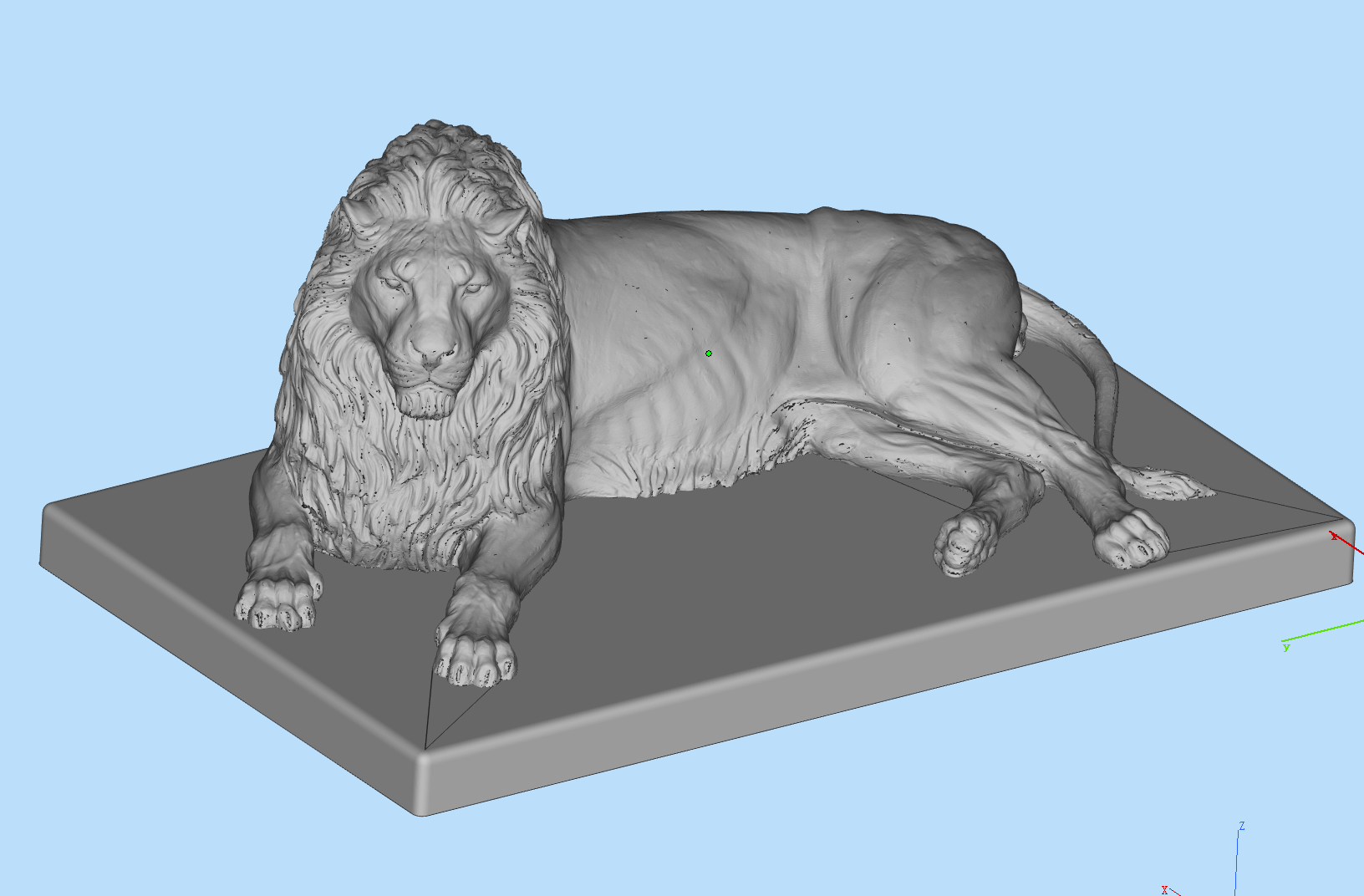

Cultural Heritage – Digitize artifacts and sculptures for preservation

Medical & Orthotics – Custom-fit prosthetics and medical devices

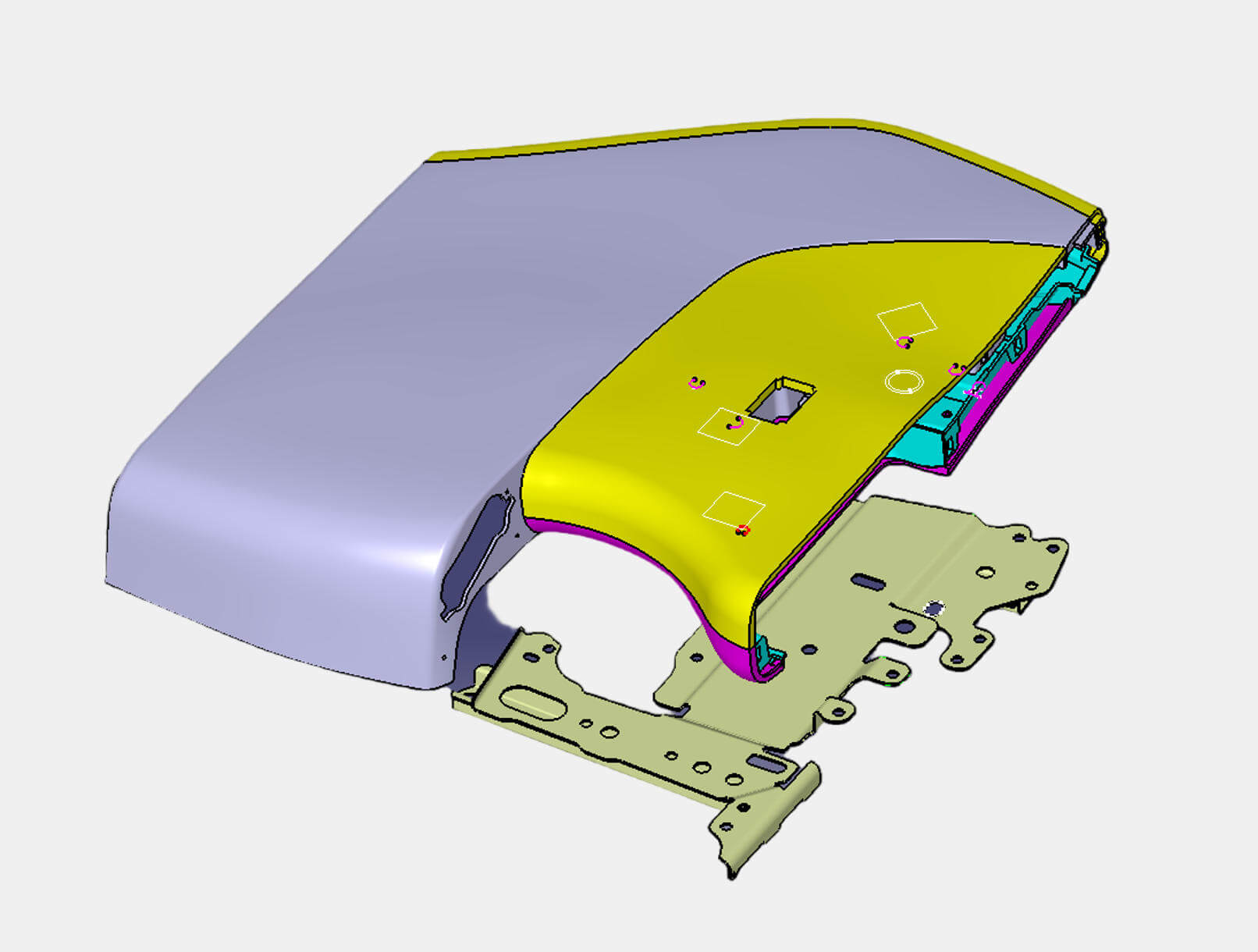

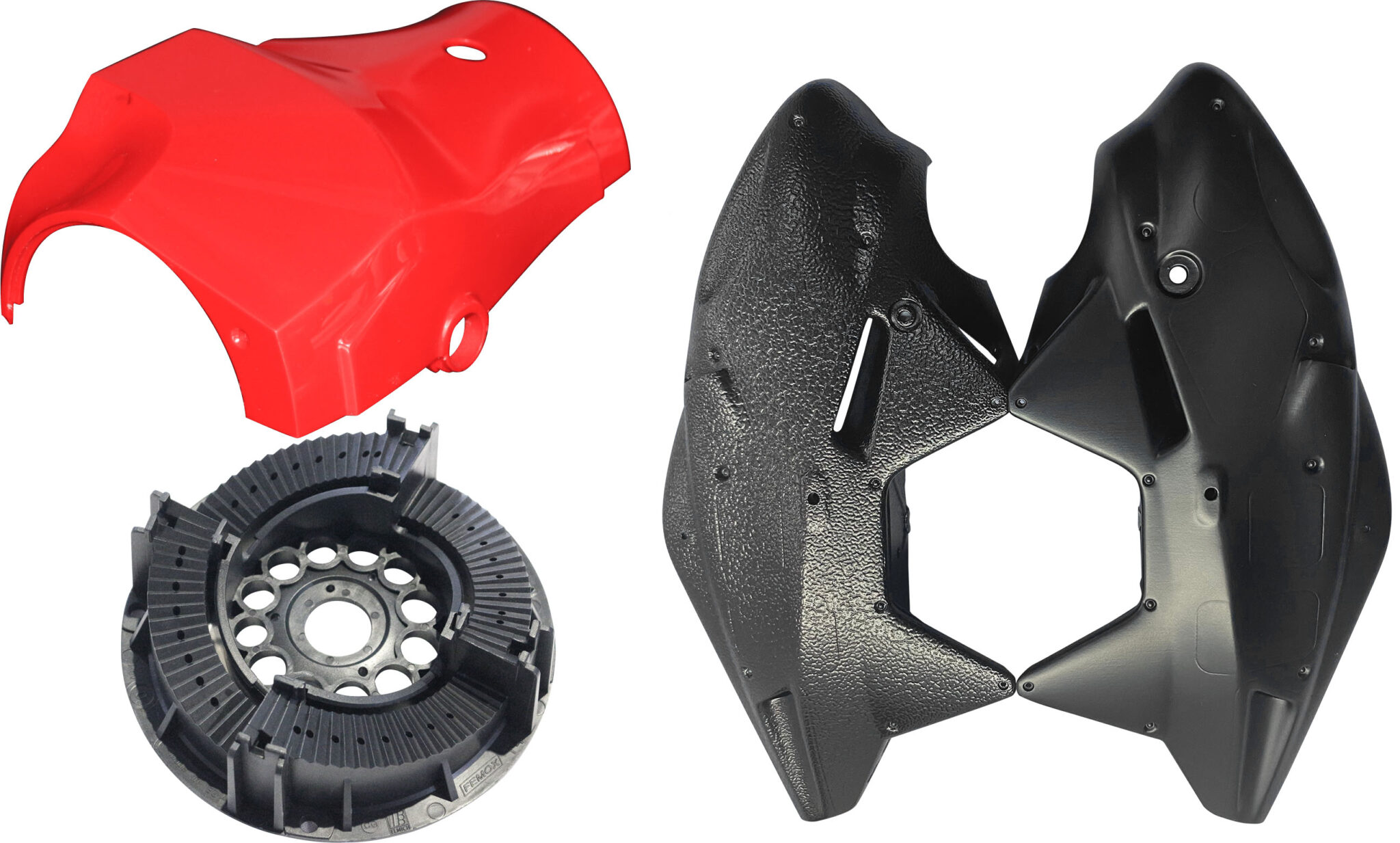

Automotive & Aerospace – Scan and reproduce complex components

Industrial Design: Capture ergonomic surfaces and product forms

One-Stop Service: From Rapid Prototyping to Mass Production

Taking your design from early-stage testing to full-scale production has never been easier. With our wide range of capabilities, we support your journey from prototyping to mass manufacturing. Let us be the backbone of your success and your trusted one-stop partner

Design Process: 3D Scanning

– Rapidly convert physical objects into CAD models to accelerate design.

Early Development: 3D Pritning

– Quick-turn parts to validate fit, form, and function at the earliest design stages.

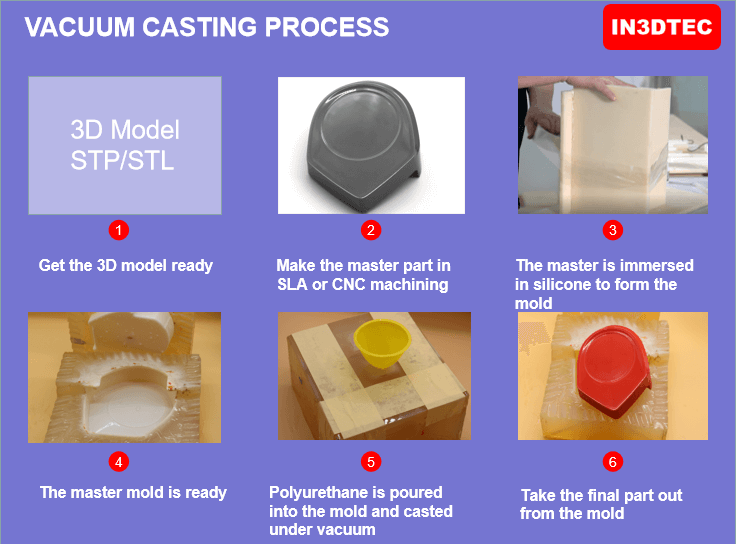

Mid Development: UrethaneCasting/Vacuum Casting

– Highly representative models that balance aesthetics and functionality for deeper design validation.

Production: Injection Molding

– Production-quality parts ready for testing, bridge runs, and full-scale manufacturing.

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

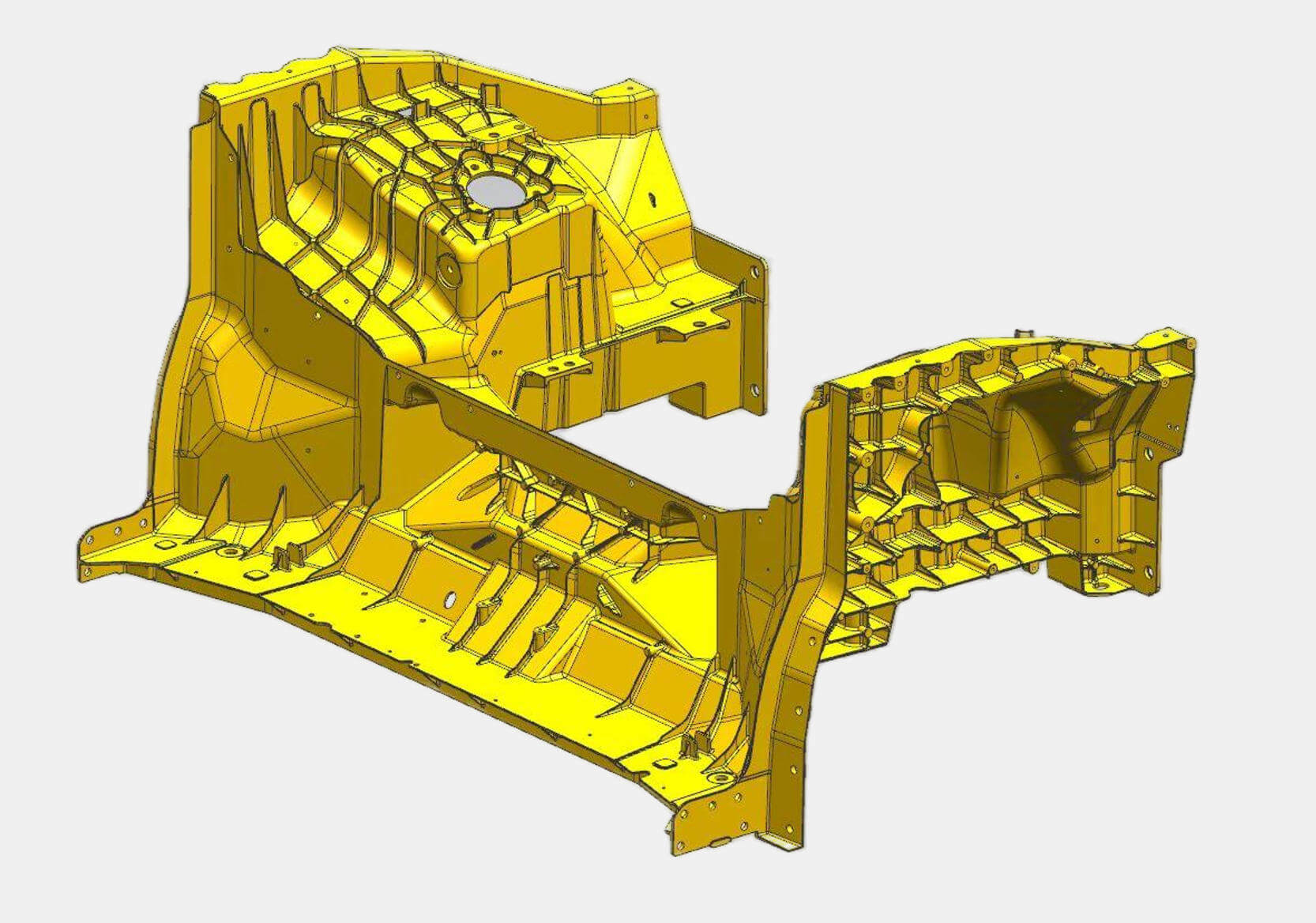

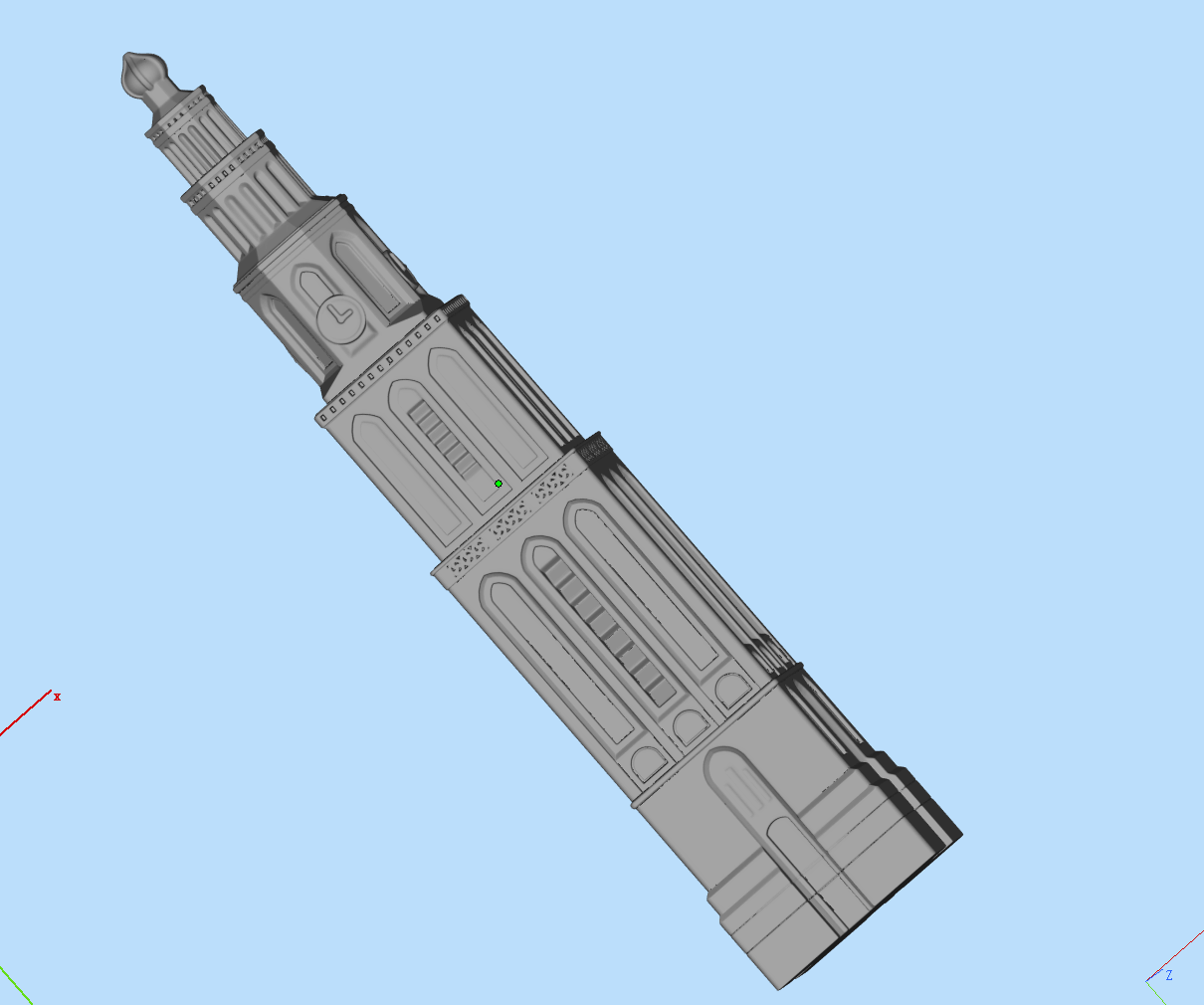

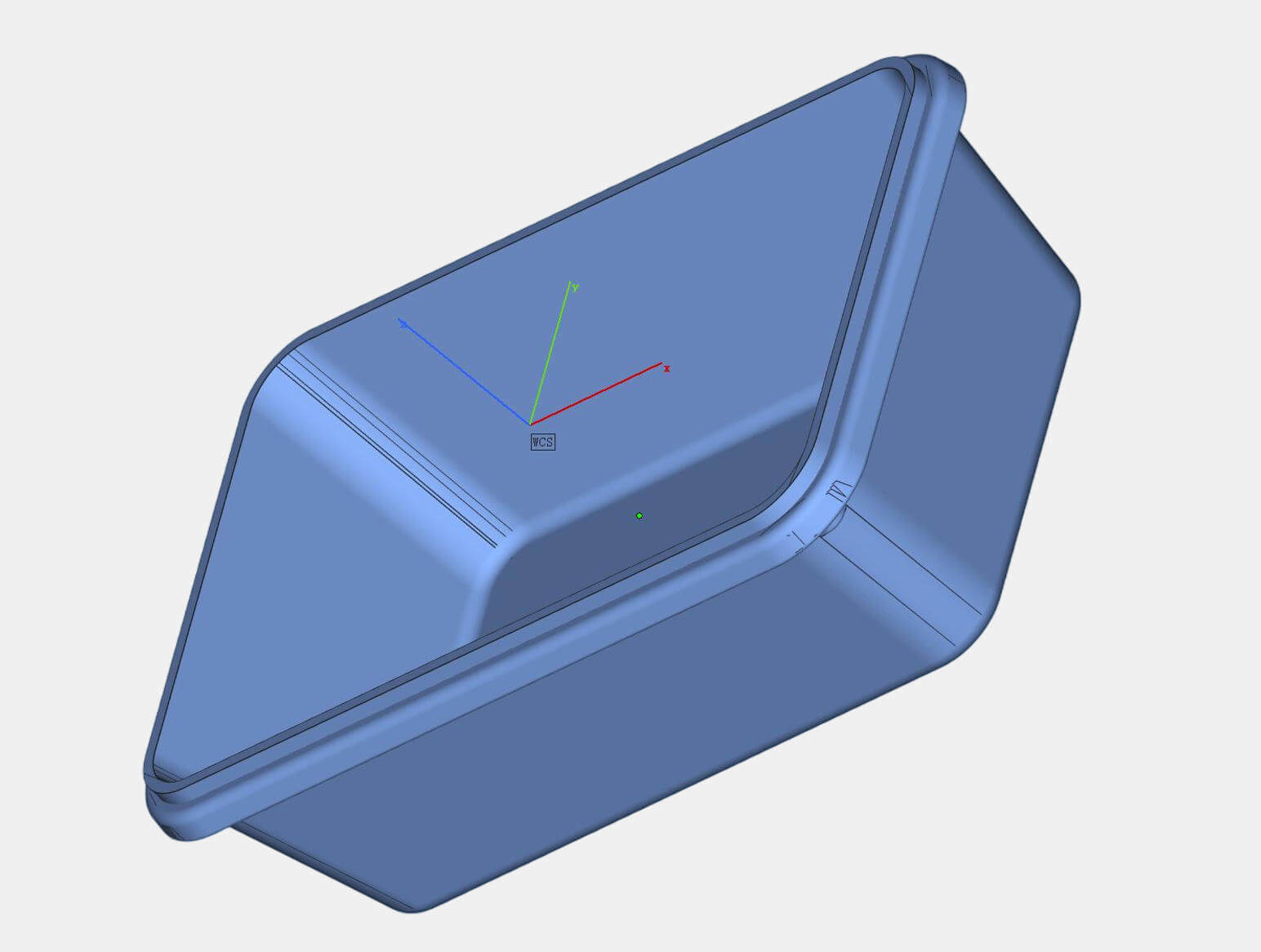

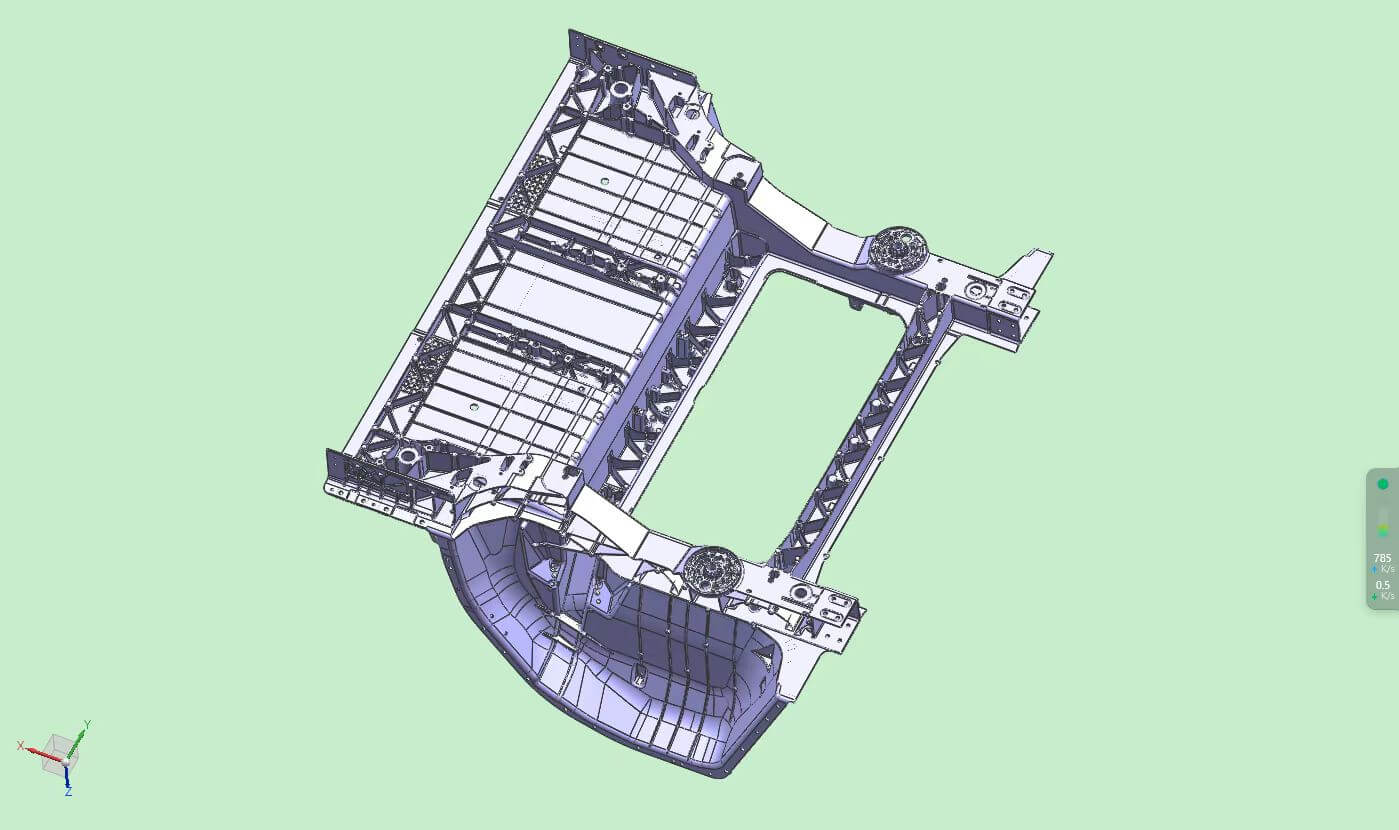

Gallery Of 3D Scanning & CAD Creating

How to Work With

Simply upload full-view photos (top, bottom, left, right) of the part with dimensions.

We will provide you with a quote within 1 business day.

As we are based in Shanghai China, we need the parts to be shipped to us.

We deliver the CAD files as required.

Manufacturing Resources

View All

Vacuum Casting Vs 3D Printing Vs Injection Molding, what's the difference

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today.

Read More

All you need to know about vacuum casting

Welcome, curious minds and DIY enthusiasts, to our comprehensive guide on the fascinating world of vacuum casting!

Read More

What is Vacuum Casting? Vacuum casting vs 3D Printing Vs Injection Molding vs injection Molding

This article aims to help users understand the process and advantages of vacuum casting, then choose more suitable materials when developing new products. As usual, the article is divided into the following sections.

Read More

Top Free Tools for Repairing STL Files in 3D Printing

3D printing has revolutionized the way we create objects, but it’s not without its challenges. One common issue that many enthusiasts face is dealing with corrupted or flawed STL files. Fortunately, there are several free tools available that can help you

Read MoreQ & A

A: Yes, We need the part to be shipped to Shanghai, China.

A: Affordable, fast turnaround, excellent customer service.

A: Automotive, consumer electronics, medical devices, robotics, and industrial design prototyping.

A: Typically ±0.02 mm

A: STP file is editable for further design, STL is not.

A: For simple parts, creates STL format takes 1 day, STP file needs 2-3 working days. Complex parts take longer.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文