HP Multi Jet Fusion (MJF) 3D Printing — Fast, Functional, Production-Ready Parts

High-throughput, repeatable nylon parts for prototypes and short-to-mid production runs.

What is MJF 3D Printing?

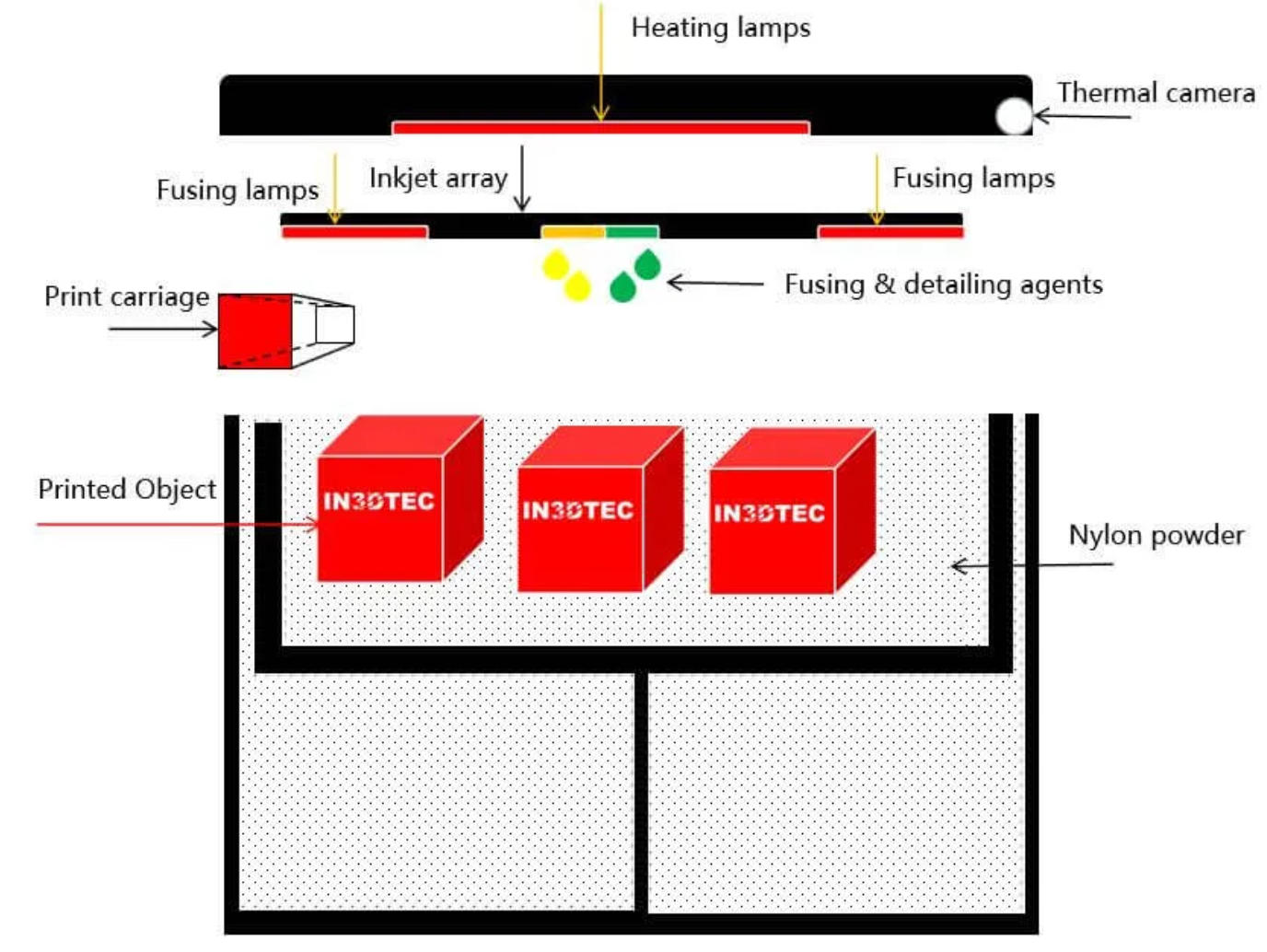

MJF uses inkjet arrays to deposit fusing and detailing agents onto a powder bed, then fuses layers with thermal energy — voxel-level control for high throughput and consistent mechanical properties.

High Mechanical Strength – Excellent isotropic properties.

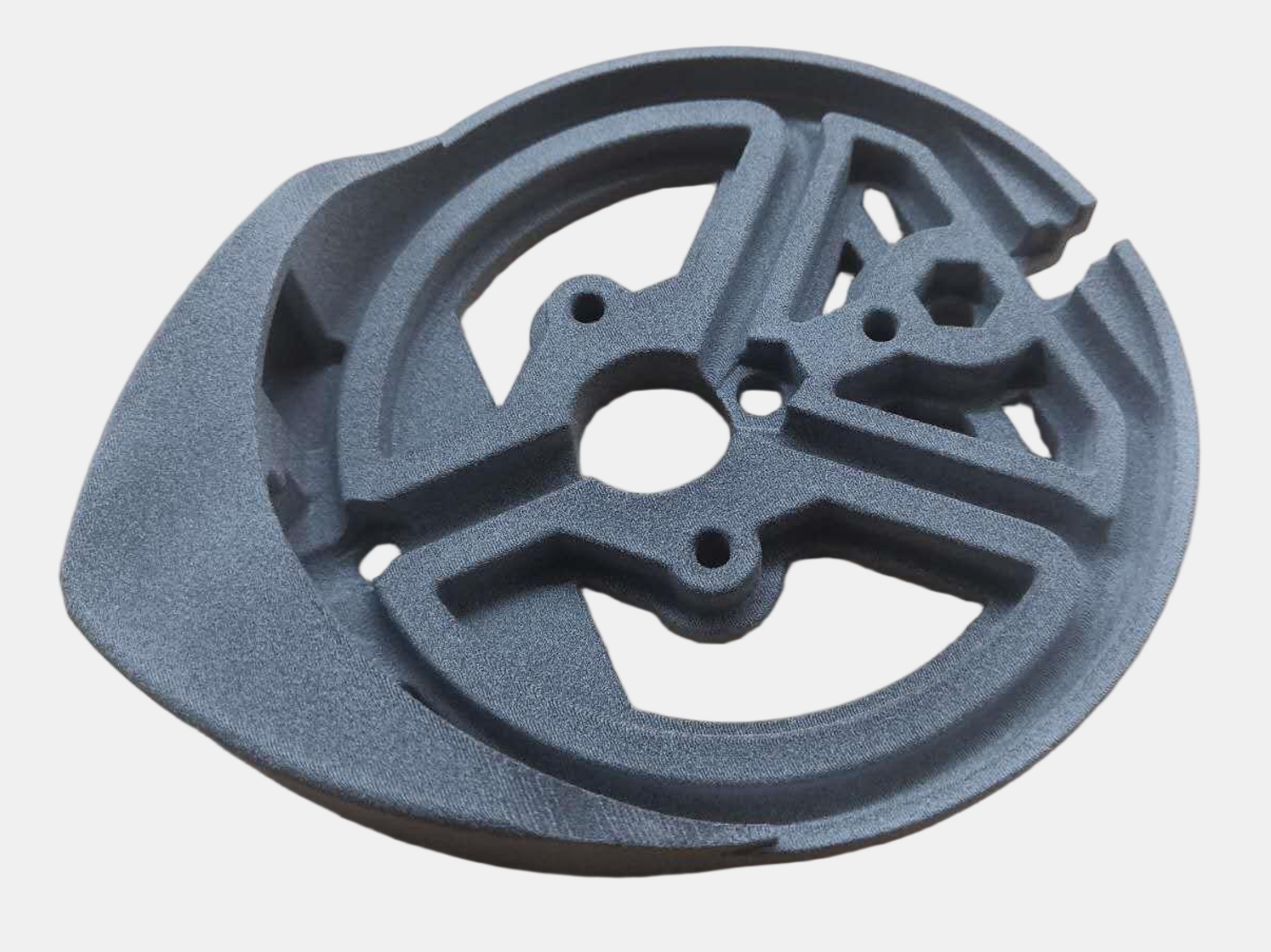

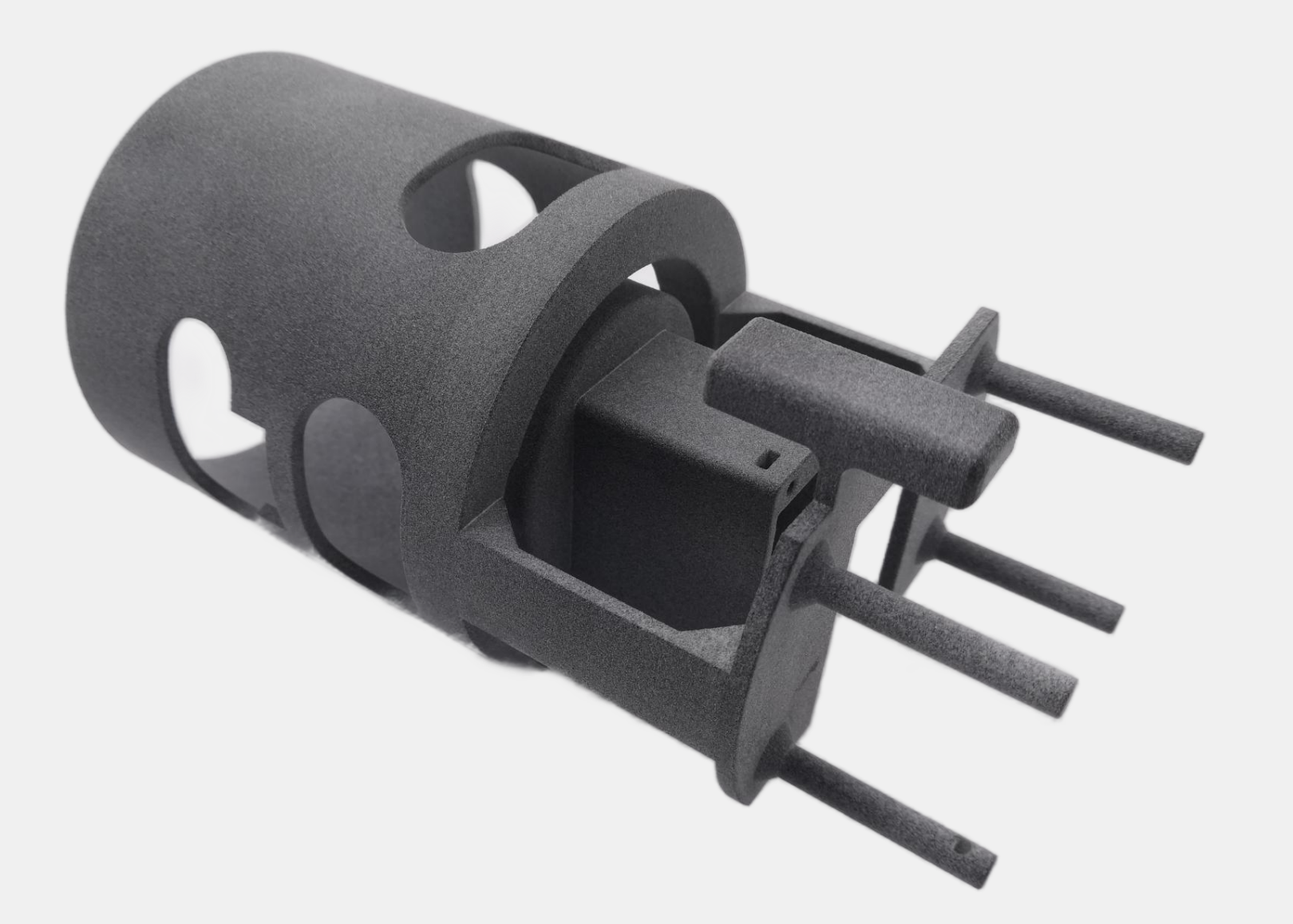

Fine Detail & Accuracy – Thin walls, sharp edges, complex geometries.

No Support Structures – Unfused powder acts as natural support.

Fast Turnaround – Batch production in hours, not weeks.

Cost-Efficient – Optimized for both prototyping and small series production.

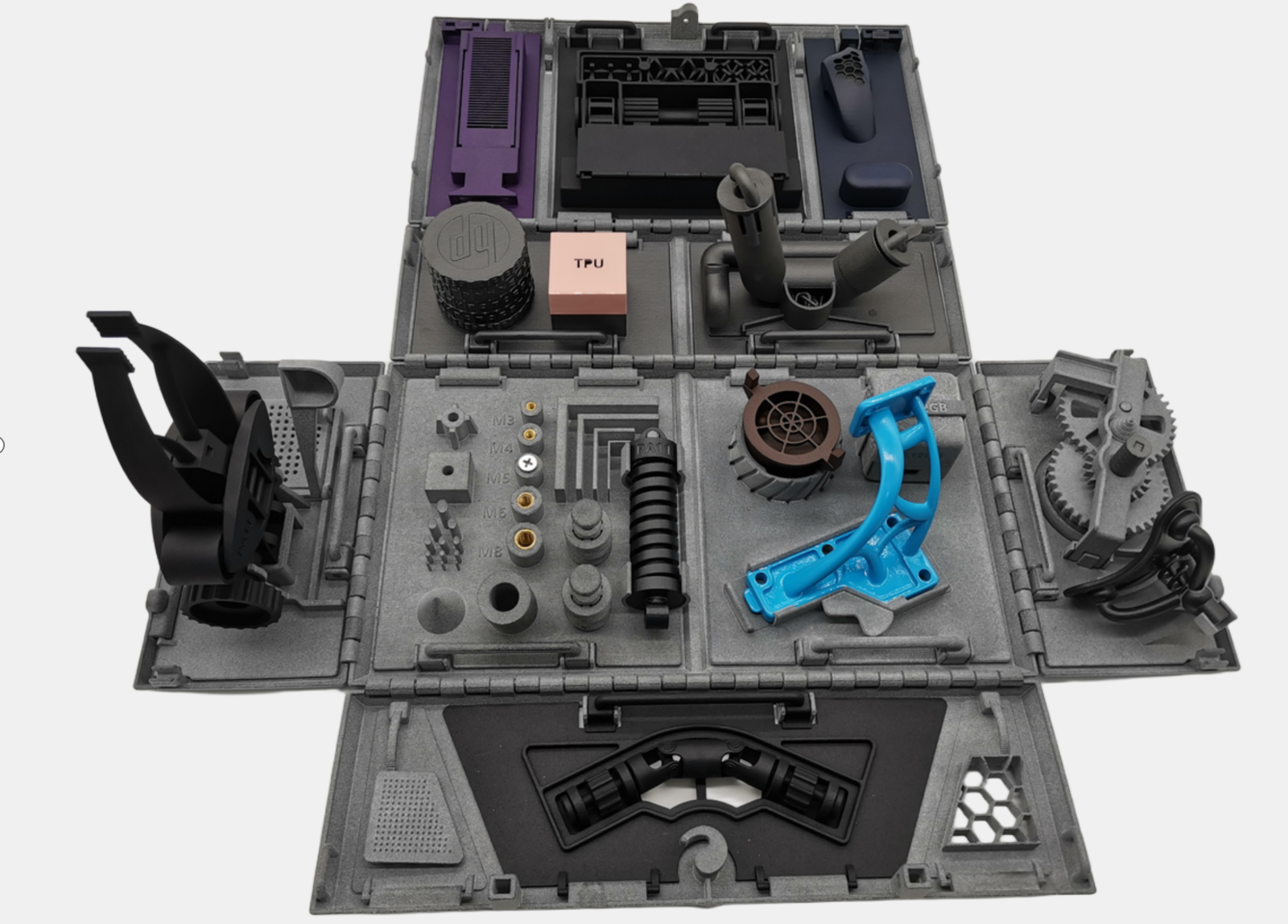

Multi Jet Fusion (MJF) Materials

We offer over 100+ 3D Printing materials and a wide range of surface finishes, and we also support customized materials for special projects

Surface Finishes For MJF 3D Prints

Improve durability and performance with a selection of finishes.Bead blasting

Color Matching/Painting

Polishing

Dyeing

Tumbling

Insert

Electroplating

Why IN3DTEC For Multi Jet Fusion (MJF)

From idea to production, we help you get there faster.

300+ Industrial Printers

– HP,EOS, Stratasys, Farsoon, BLT & more.

All Major Technologies

– FDM, SLA, SLS, MJF, SLM, PolyJet, MBJ, Ceramic, Sand Print & Metal Casting.

Broad Material Options

– 100+ Plastics, metals, composites, and custom materials.

Fast Turnaround

– Speed without compromising quality.

Expert Support

– Design optimization & engineering guidance.

Strict Quality Control

– Certified processes, reliable results.

Scalable Production

– From prototypes to mass production.

Global Service

– Worldwide delivery & logistics support.

Competitive Pricing

– Flexible and cost-effective solutions.

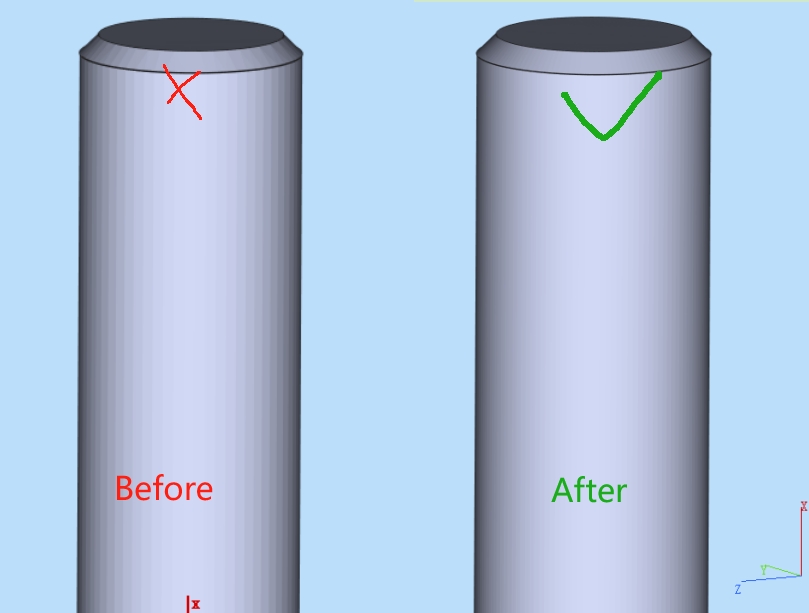

Walls are too thin, minimum recommended thickness value is 1.0

Show thin walls

From Quote To Delivery

Everything You Need In One Easy-to-use Platform

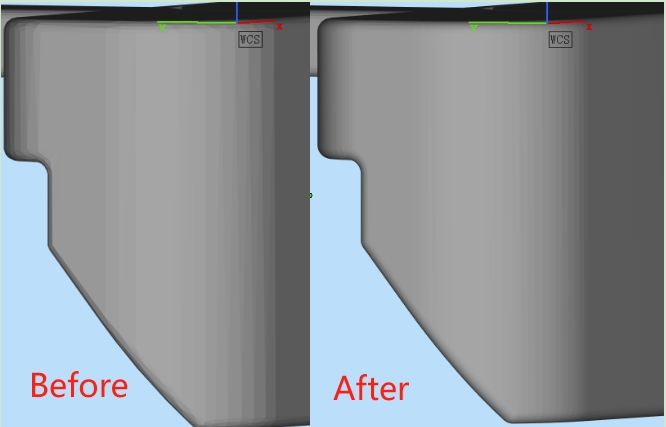

Our AI-powered online quoting tool delivers prices within seconds and makes order tracking and management effortless. With built-in DFM capabilities, it helps identify design errors early, saving you time and ensuring smoother part production.

No Minimum Quantity | AI-Powered DFM Analysis |Online Order Management | Flexible Lead Time & Shipping Options

“IN3DTEC is a wholly trusted partner. They help us develop new products more efficiently and quickly. High-quality products and competitive prices are also why we recommend them to more people.” Luis Ford at Leica Medical Product Design Team

Excellent 4.9 out of 5

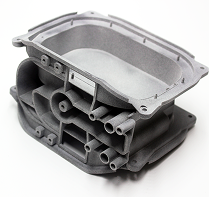

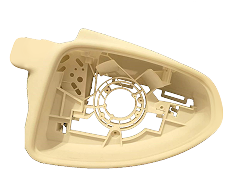

Gallery Of Multi Jet Fusion (MJF)

How Does MJF 3D Printing Work

Powder Layering – A thin layer of powder is spread over the build platform.

Jetting Agents – Fusing and detailing agents are selectively jetted onto the powder.

Energy Fusion – Infrared energy passes over the layer to fuse the powder.

Layer by Layer – The process repeats until the full part is built.

Cooling & Post-Processing – Excess powder is removed, and parts are cleaned or finished.

How to Work With

Simply upload your CAD files.

Get real-time pricing and DFM insights within seconds. Or ask for manual design help.

Once your order is placed, we’ll begin production right away, and you can track and manage it anytime from your dashboard.

Partnering with FedEx, DHL, and UPS, we deliver your parts fast and on time, worldwide.

Put your Parts into Production Now

Manufacturing Resources

View All

How to Export Your CAD Files for a Smoother Surface Finish

In the world of 3D printing and manufacturing, the quality of your final product is heavily influenced by how you export your CAD files. A smooth surface finish can enhance aesthetics, improve functionality, and reduce post-processing work. In this blog,

Read More

How to Export Your CAD Files for a Smoother Surface Finish

In the world of 3D printing and manufacturing, the quality of your final product is heavily influenced by how you export your CAD files. A smooth surface finish can enhance aesthetics, improve functionality, and reduce post-processing work. In this blog,

Read More

HP MJF Surface Treatment Simplify explained

This article helps you choose a suitable surface treatment by introducing the post-processing process of MJF 3D printing.

Read More

What's the difference between slS and mJF 3D Printing

The main difference between SLS and MJF 3D Printing is the cost then followed by the productivity, surface smoothness, surface treatment, types of materials, ect. We believe readers who read this article already had a basic explanation for both SLS and M

Read More

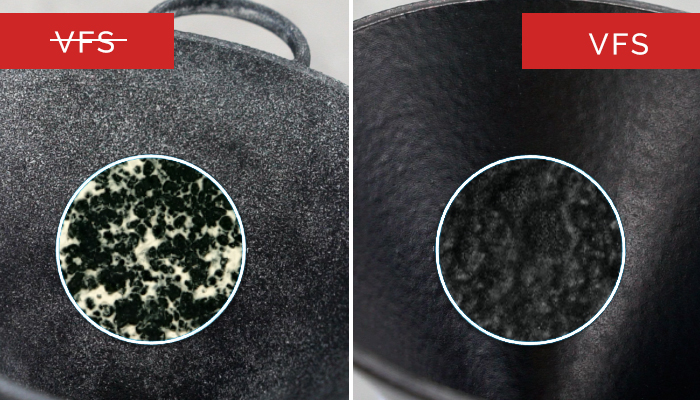

VaporFuse Surfacing an enhanced post-treatment for your 3D parts

With the constant growth of Additive Manufacturing and its fields of application, the demand for 3D-printed parts is also increasing. Today, market-ready products manufactured with Powder Bed Fusion technologies such as Selective Laser Sintering (SLS) or

Read MoreQ & A

A: 380X284X380mm

A: 0.5mm

A: Nope

A: Accuracy: ±0.3% (min ±0.25 mm)

A: Balance results in smoother surface, better strength & uniform color.

A: Yes, MJF is ideal for short-run production with consistent quality.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文