- Author

- 25 February 2026

Vacuum Casting Vs 3D Printing Vs Injection Molding, what's the difference

Vacuum Casting, 3D Printing, and Injection Molding are three widely used methods for manufacturing plastic products today. Determining the right choice for your projects requires a breakdown of their differences and an exploration of their respective benefits and drawbacks.

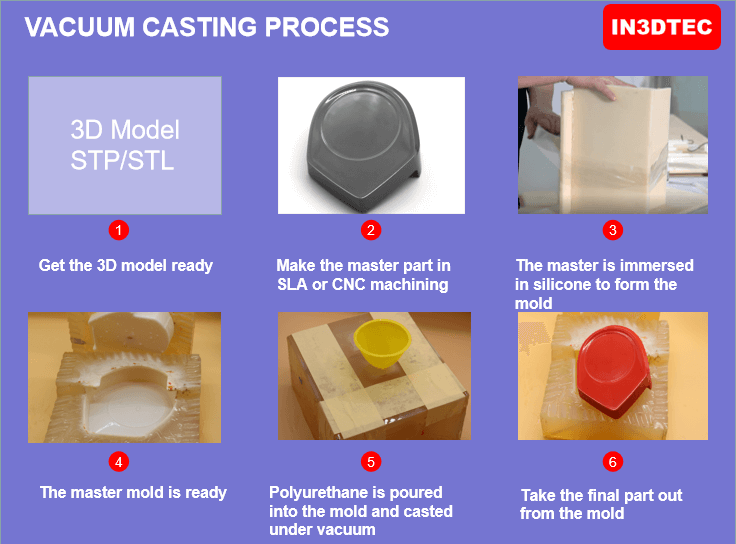

Vacuum Casting Process

Vacuum casting is a process of making molds using silicon based materials. This material is heated until it becomes liquid, and then poured into a mold made using the main model or prototype. Once the material solidifies, the part can be removed from the mold and any excess material can be trimmed. The main advantage of vacuum casting is that it can fill small cracks or details in the prototype, thus creating more complex shapes.

Advantages:

Compared with 3D Printing: Its materials have superior strength and temperature resistance, with a smoother surface and support for multiple colors.

Compared with Injection Molding: No need for making a high-cost steel/aluminum cost for low-volume production.

Disadvantages:

Each cycle takes up to 6-8 days, which means that the production time is slower than 3D Printing. In addition, vacuum casting is limited by mold size and can’t make super high complex parts.

3D Printing

Additive manufacturing or 3D printing is defined as the process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies.

As 3D Printing can create objects directly from the digital model, it is increasingly today to make proofs, Prototypes, and low-volume production end-use parts.

Advantages:

It can make high complex geometric parts within 1 day without using extra tooling. This means that you can quickly modify your design without having to recreate moulds whenever you want to make changes.

Disadvantages:

The current materials still have limitations, especially for components with high requirements for mechanical and chemical properties. Additionally, the printed sample will have layer patterns on the surface.

Injection Molding

Injection molding is the most cost-effective way to make a plastic part at scale and offers consistent quality for low-to-high- volume manufacturing.

Advantages:

Molding also has the highest variety of materials, colors, and configurations when compared to Vacuum Casting and 3D Printing.

Disadvantages:

Long-time lead time( 25 days).

Difference: Vacuum casting, 3D Printing and Injection Molding

- Cost: For low-volume production, 3D Printing is the most cost-effective way, then followed by Vacuum Casting, and Injection molding.

- Materials: Injection molding supports various materials than vacuum casting and 3D Printing. The materials (plastics) in 3D Printing are ideal for prototyping.

- Surface finishes: Parts mixed with pigment are valid on vacuum casting and injection molding. Injection molding supports many types of textures. However, 3D Printing ( plastics) has limited finishes available.

- Lead time: 3D Printing is the fastest.

- Tolerance: Injection molding>Vacuum Casting>=3D Printing

- Quality Consistent: Injection Molding>Vacuum Casting>= 3D Printing

In Summary:

Vacuum casting and 3D printing are excellent methods for creating custom parts within days.

Vacuum Casting and Injection molding are ideal for low to large-volume parts used directly for marketing sales.

Ultimately the decision comes down to what type of part you need to be produced; consider all your options before deciding which method best meets your needs!

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文