- Author

- 12 January 2026

Exploring the difference: Metal 3D Printing Vs CNC Machining

In the world of manufacturing, two cutting-edge technologies have emerged as game-changers: Metal 3D printing and CNC machining. Both processes offer unique advantages and have revolutionized the way we design and produce metal parts. In this article, we will delve into the characteristics, benefits, cost considerations, and design factors of these two technologies to assist you in determining which one is better aligned with your specific requirements.

What is metal 3d printing?

Metal 3D printing, also known as additive manufacturing or metal additive manufacturing, is a manufacturing process that involves creating three-dimensional objects by adding layers of metal material on top of each other. It is a subset of 3D printing that specifically focuses on the fabrication of metal components.

What are the benefits of metal 3d printing?

- Reducing the tooling cost: Different to CNC machining, Metal 3D Printing doesn’t need any jigs and fixtures when manufacturing. This save a lot of time and cost for developing tools. Especially for customized complex parts.

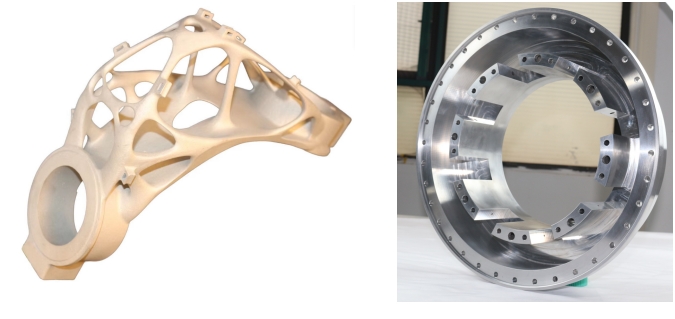

- Design freedom: This advantage is not achievable by many other traditional manufacturing techniques, including CNC machining. For example, when machining an S-shaped exhaust pipe, the tools used in CNC machining cannot reach the interior of the pipe, making it impossible to complete the machining process. However, 3D printing can easily accomplish this. Additionally, features such as blind holes, undercuts, internal right angles, lattice structures, and more can only be achieved through 3D printing.

- Material Efficiency: With CNC machining, excess material is often removed from a solid block, resulting in substantial material loss. In contrast, metal 3D printing builds parts layer by layer, using only the necessary amount of material. This reduces waste and optimizes material usage, making it cost-effective, particularly when working with expensive metals or scarce materials, such as Titanium, Nickel Alloy, Co-Cr…

- Lightweight and Optimized Parts: Lightweight applications have been a hot topic in recent years due to the practical economic benefits associated with reducing the weight of components. For example, reducing the weight of an aircraft can lead to significant fuel savings. Similarly, reducing the weight of a race car can result in increased speed. As a result, an increasing number of metal users are incorporating lattice structures, hollowed parts, or utilizing topology optimization and generative design to achieve weight reduction. This presents a significant prospect for the widespread future application of metal printing.

How much does it cost by metal 3d printing?

The cost of metal printing is often influenced by several key factors, including machine operating costs, part volume, part weight, and post-processing.

Machine Operating Costs: Machine operating costs include factors such as gas replacement frequency, laser maintenance, and scraper replacement. The impact of different part designs on machine operating costs is usually not significant. However, many metal printing service providers consider production efficiency when assessing costs.

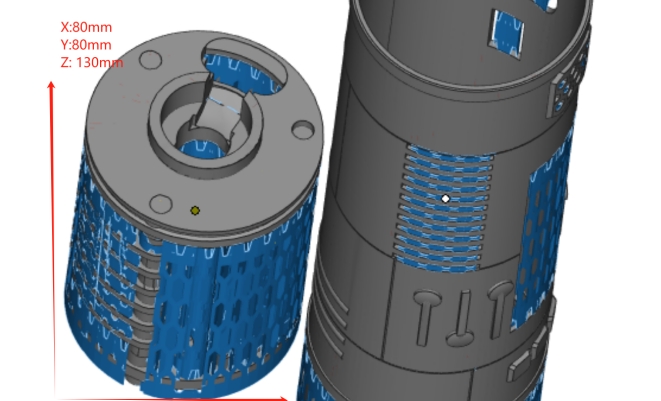

Part Volume and Weight: These two variables are primary factors determining the cost of metal printing. For example, keeping other variables constant, a significant reduction in weight can lead to a noticeable cost decrease. Similarly, the size of the part is directly proportional to the cost.

Post-Processing: Post-processing considerations involve labor costs. For instance, in the example below, the part is only 10 cm in size, and the printing cost itself is much cheaper than CNC machining. However, due to the time-consuming nature of post-processing, it can increase the overall cost.

What is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a manufacturing process that utilizes computer-controlled machines to remove material from a workpiece. It involves the use of pre-programmed instructions to guide the cutting tools and perform precise and automated operations such as drilling, milling, turning, and grinding. Learn More.

How Much does CNC Machining cost?

The cost of CNC machining service can include the following components: material cost, programming fees, machining labor hours, Jigs & fixtures cost, and machine costs.

Material cost: For example, if you need to machine a sample with dimensions of 10 cm in length, width, and height, when calculating the material cost, you should add an additional 5-10 mm for each dimension to account for the allowance. This will enable you to determine the weight and cost of the material needed.

Programming fees: Programming fee based on the part’s complexity and material’s type ( titanium is higher than aluminum). This is a basic cost that is relatively easy to understand. When the number increases, this cost can be divided evenly and thus reduced.

Machining labour hours: Unlike metal 3D printing, CNC processing requires frequent manual intervention, which means higher labor costs.

Jigs & fixtures cost: The more complex of the part the higher jigs cost. However, Metal 3D Printing doesn’t affect by this.

Machine costs: The cost of the machine includes regular maintenance, replacement of spare parts, tooling, and depreciation. Compared to metal 3D printing, the maintenance of CNC equipment tends to be more complex. However, if it doesn’t involve core components, the cost of individual repairs is relatively low.

What’s the advantages of CNC machining compared with Metal 3D Printing?

| Technology | Material Type | Tolerance | Smoothness | Stability |

| CNC | 30+ | +/-0.03 to+/-0.1mm | Ra1.6 or higher | Excellent |

| Metal 3D Printing | Less than 10 | +/-0.1 to +/-0.2mm | Ra 7 | Good |

(Remark: The above comparison assumes that the two parts are originally processed without any secondary processing.)

What’s the disadvantages of CNC machining compared with Metal 3D Printing?

| Technology | Structural difficulty | Lead Time | Material Efficiency | Machine Operation difficulty |

| CNC | Complex | 6-8 B days | Low | Difficult |

| Metal 3D Printing | Extremely complex | 4-6 B days | High | Normal |

CNC Machining VS 3D Printing, which cost is lower?

To understand exactly the cost of 3D Printing & CNC Machining, we recommend you upload files to online 3D Printing or Online CNC Machining platform to get a cost

Conclusion:

Metal 3D printing and CNC machining are both remarkable manufacturing technologies, each with its own strengths and considerations. Metal 3D printing excels in design freedom, rapid prototyping, and material efficiency, while CNC machining offers exceptional surface finish, precision, material selection, and cost-effectiveness for certain applications.

To determine the most suitable method for your specific manufacturing needs, analyze factors such as part complexity, desired surface quality, material selection, production volume, and budget. In many cases, a hybrid approach that combines the strengths of both metal 3D printing and CNC machining may be the optimal solution.

Ultimately, the choice between metal 3D printing and CNC machining depends on the specific requirements of your project. Embracing these advanced manufacturing technologies unlocks new possibilities and empowers manufacturers to bring innovative designs to life in the most efficient and effective ways possible.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文