- Author

- 12 January 2026

The 11 Biggest Metal 3D Printing Service Companies Revolutionizing Manufacturing

Introduction:

Metal 3D printing has emerged as a transformative technology, enabling the production of complex and customized metal parts with unprecedented precision and efficiency. This innovative approach to manufacturing has revolutionized industries such as aerospace, automotive, transportation, healthcare, energy, and more. In this article, we will explore the 11 biggest metal 3D printing companies that are leading the way in this rapidly evolving field.

1.EOS:a pioneering company and a global leader in industrial metal 3D printing.

Founded in Germany, EOS has been at the forefront of additive manufacturing since its establishment in 1989. EOS is a pioneer and global leader in industrial metal 3D printing, They provide a comprehensive range of metal 3D printing solutions, including machines, software, and materials. EOS’ Direct Metal Laser Sintering (DMLS) technology allows for the production of high-quality metal components with excellent mechanical properties. With a strong focus on innovation and reliability, EOS has established itself as a trusted partner for businesses seeking metal 3D printing services. There are some metal 3d printing service companies using EOS for making excellent parts such as Materialise, IN3DTEC.

2.SLM Solutions:a global leader in metal 3D printing, specializing in selective laser melting (SLM) technology.

Founded in 2006 and headquartered in Germany, the company has established itself as a trusted provider of high-quality metal 3D printing solutions. SLM Solutions is a leading provider of metal-based additive manufacturing technology. Their selective laser melting (SLM) technology enables the production of complex metal parts by selectively melting metal powders layer by layer. SLM Solutions offers a range of high-performance metal 3D printers and comprehensive support services. Their solutions find applications in various industries, including aerospace, automotive, and medical.

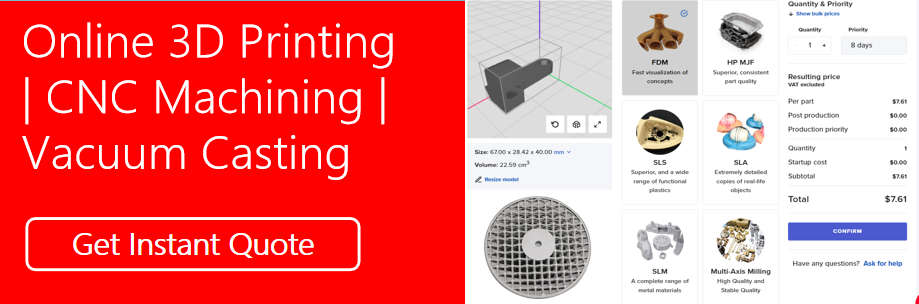

3.IN3DTEC: Online Metal 3D Printing, CNC Machining, Vacuum Casting, injection molding service company

Founded in 2014. A well-known metal 3d printing company boasting over 300 pieces of equipment, IN3DTEC’s online digital management system swiftly generates metal 3D printing quotes within seconds for its customers.

Notably, the company can deliver 3D prints in as little as one day, underscoring its commitment to rapid and efficient production. IN3DTEC offers a range of solutions tailored to diverse applications, spanning implants and dental components for the medical field, housing and automotive gears, oil & gas pipes, impellers, and lattice structures for transportation and aerospace sectors. All metal prints meet ISO standard quality assurance criteria.

Their diverse manufacturing capabilities, global presence, and digital platform make them a preferred choice for companies seeking quick and reliable manufacturing solutions.

4.GE Additive: a leading company in the field of additive manufacturing, specifically focused on metal 3D printing

GE Additive, a subsidiary of General Electric, is at the forefront of metal 3D printing innovation. They offer a range of metal 3D printers, including the renowned Concept Laser and Arcam brands. GE Additive’s technologies, such as laser powder bed fusion (LPBF), allow for the production of high-quality metal components with exceptional precision. With their extensive expertise and resources, GE Additive continues to drive advancements in metal additive manufacturing.

5.Renishaw: a global engineering company known for its involvement in metal 3D printing and metrology solutions.

Founded in 1973 and headquartered in the United Kingdom, Renishaw has established itself as a leader in precision engineering and manufacturing. Renishaw is a global engineering company that has made significant contributions to the metal 3D printing industry. They offer metal 3D printers utilizing their patented laser powder bed fusion (LPBF) technology. Renishaw’s printers are known for their accuracy, reliability, and ability to produce complex geometries in a wide range of metals. Renishaw’s expertise extends to sectors such as aerospace, medical, and automotive, where they have enabled the production of critical components.

6.Desktop Metal:a company that focuses on making metal 3D printing more accessible and affordable

They were founded in 2015 with the goal of revolutionizing manufacturing through their innovative approach to additive manufacturing. Desktop Metal is a company focused on making metal 3D printing more accessible and affordable. They offer a range of metal 3D printers, including both binder jetting and extrusion-based technologies. Desktop Metal’s solutions cater to various applications, from rapid prototyping to low-volume production. Their commitment to advancing metal 3D printing technology has gained them recognition in industries such as automotive, consumer goods, and electronics.

7.Materialise:a pioneering company in the field of 3D printing and additive manufacturing.

Founded in 1990 and headquartered in Belgium, Materialise has become a leading provider of software solutions and 3D printing services.

One of Materialise’s core offerings is their software suite, which includes a range of specialized tools for 3D printing, design optimization, and simulation. Their software enables users to efficiently prepare, optimize, and analyze 3D models for additive manufacturing, ensuring high-quality and reliable production.

These services cater to diverse industries, including healthcare, automotive, aerospace, and consumer goods. Materialise’s service bureaus provide expertise and production capabilities for both prototyping and end-use part production.

8.Protolabs: a global leader in digital manufacturing and rapid prototyping services

Founded in 1999 and headquartered in the United States, Protolabs offers a range of manufacturing processes, including 3D printing, such as ABS, nylon, aluminum, steel.

Protolabs specializes in providing quick-turnaround manufacturing solutions, allowing customers to rapidly create prototypes, produce low-volume parts, and accelerate product development cycles.

The company operates a global network of manufacturing facilities, strategically located to serve customers worldwide.

9.Shapeways: a global 3D printing service and marketplace that enables individuals, designers, and businesses to bring their ideas to life through additive manufacturing

Founded in 2007, Shapeways has established itself as a prominent player in the 3D printing industry.

Shapeways provides a streamlined process for customers to customize and order 3D-printed products. Users can choose from existing designs available in the Shapeways marketplace or upload their own designs to be printed on-demand. The platform handles manufacturing, quality control, and shipping, making it convenient for individuals and small businesses to access 3D printing capabilities without the need for expensive equipment or extensive technical knowledge.

10.Vel3d:a company specializing in metal additive manufacturing, specifically in the field of laser powder bed fusion (LPBF) technology

Founded in 2014 and headquartered in California, USA, Velo3D has gained recognition for its innovative approach to metal 3D printing.

One of the key aspects of Velo3D’s technology is its unique SupportFree capability. Unlike traditional metal 3D printing processes that require complex support structures to ensure part stability during printing, Velo3D’s process is designed to minimize or eliminate the need for supports. This capability allows for greater design freedom, reduces post-processing requirements, and enables the production of complex geometries and internal structures that were previously challenging to achieve with metal additive manufacturing.

Velo3D’s metal 3D printers are equipped with in-situ process monitoring systems, which provide real-time feedback and control during the printing process. This enhances the overall quality and consistency of printed parts, ensuring high accuracy, repeatability, and reliability.

11.BLT: Advanced Metal Powder Forming 3D Printing Equipment Manufacturer

Founded in 2011, BLT is a metal 3D printing equipment manufacturer located in Xi’an, China. The founding team consists of university professors, and with their technological advantages, BLT has grown to become one of the largest metal equipment company in China.

The company invests significant resources into exploring new materials, printing techniques, and software solutions to enhance the capabilities of their 3D printers. Through collaborations with universities, research institutions, and industry partners, BLT actively contributes to the advancement and innovation of 3D printing technologies.

Conclusion:

Metal 3D printing is transforming the way we manufacture metal components, offering unparalleled design freedom, reduced lead times, and cost-effective production. The 11 companies mentioned in this article are at the forefront of this revolution. Through their cutting-edge technologies, comprehensive services, and industry expertise, they have paved the way for innovation across a wide range of sectors. As metal 3D printing continues to evolve, these companies will undoubtedly shape the future of manufacturing and drive further advancements in this groundbreaking field.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文