- Author

- 12 January 2026

What is ceramic 3d printing and how it works?

How Ceramic 3D Printing works?

Ceramic is a traditional inorganic material, exquisite and practical. The characteristics of hardness and brittleness make it particularly difficult for ceramic materials to be processed and formed.

The development of ceramic 3D printing technology has made it possible to prepare complex ceramic products. This article is a summary of the principles of ceramic 3D printing, as well as the advantages and disadvantages of different types of ceramic 3D printing technologies.

There are five standard ceramic printing technologies; we analyze each technology to let you know what ceramic printing is and the advantages and disadvantages of each ceramic printing.

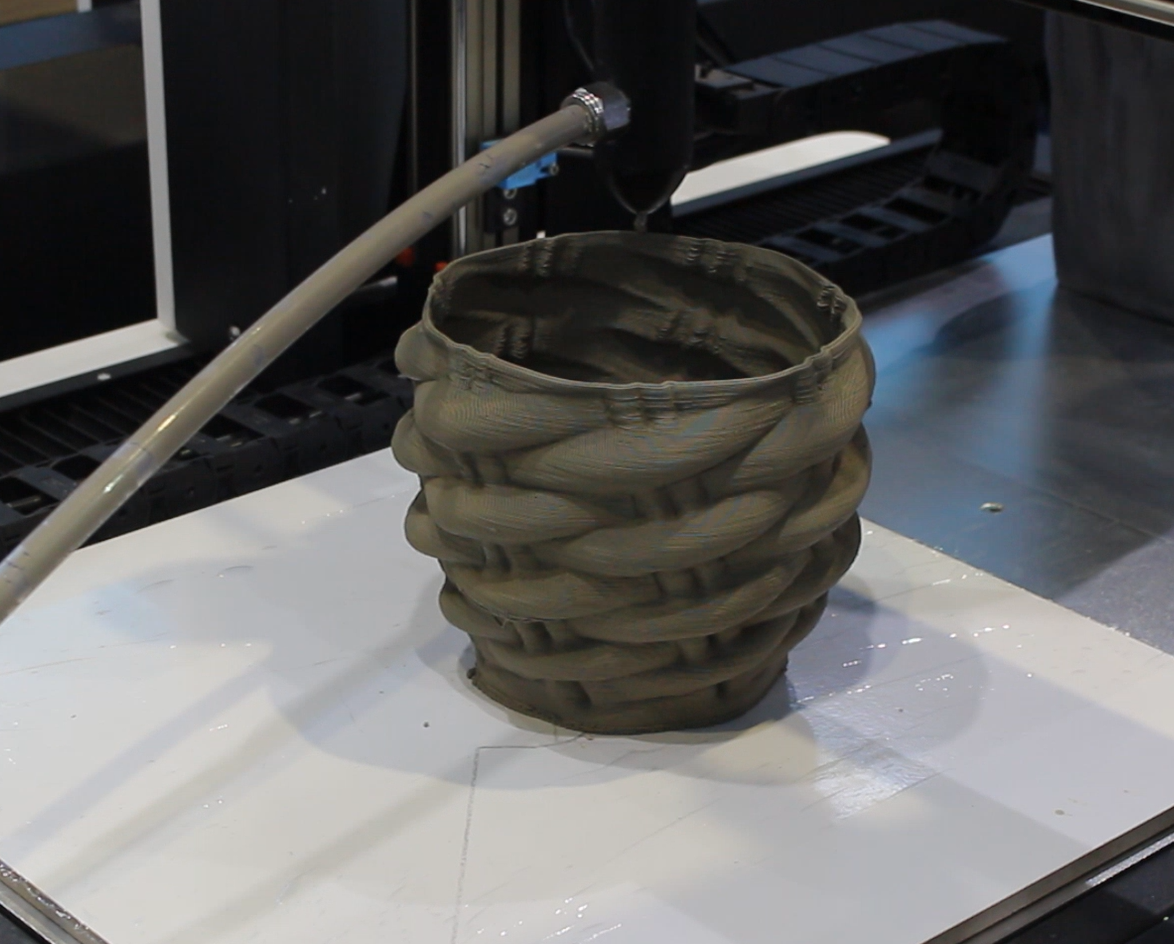

Fused deposition of ceramics,FDC

In brief, FDC combines Fused Deposition Modeling (FDM) using nozzle heating and Direct Ink Writing (DIW) technology with solvent added.

The principle of extrusion molding refers to adding solvents or physical heating to enable ceramic raw materials to have a certain fluidity. Through extrusion, a material is extruded from an extrusion nozzle with a specific diameter (usually several hundred micrometers to a few millimeters in diameter), forming ceramic parts layer by layer.

Compared with FDM 3D Printing, FDC technology’s characteristic is mixing the ceramic powder with an organic binder and adding an amorphous binder. The ceramic green body is prepared by computer control and then degreased and fired into components under suitable high-temperature conditions. The composite material is placed in an extruder and melted at a temperature slightly higher than its melting point.

Scope of application: Ceramic materials suitable for this process must have specific mechanical and thermal properties; the designed 3D model is generally a porous form with high porosity and tubular support.

Disadvantages: Since this technology needs to be heated in advance and then cooled to shape, this requires that the 3D model should not be designed too small, and the interior should not be too dense. The reason is that when the current printing layer has been printed, the printing layer is still in a high-temperature state. If it is not completely cooled, printing again in this state will cause secondary melting, quickly leading to the deformation of the 3D printing preparation and production failure.

SLA Ceramic 3D Printing

Ceramic 3D printing technology based on SLA usually uses a slurry system containing ceramic particles mixed with photosensitive resin or a photopolymerizable liquid system of organic ceramic precursors (Preceramic Polymers-PCPs).

SLA, or photocuring, refers to a specific volume of liquid materials, such as polymer monomers, that are irradiated with light of a particular wavelength to cause a crosslinking polymerization reaction to complete curing [51]. For the 3D printing process of the slurry system mixed with ceramic particles and photosensitive resin, the resin is polymerized and crosslinked into a network structure to evenly wrap the ceramic particles dispersed in the system evenly, thus forming the solidification of the mixed material macroscopically.

Afterward, the printed part undergoes high-temperature degreasing and sintering to discharge and densify the resin organic matter. The ceramic particles further diffuse and increase to form the final sample.

This heat treatment stage is similar to the traditional ceramic manufacturing method. The photosensitive polymerizable liquid system of organic ceramic precursors is identical to the 3D printing process of ordinary photosensitive resins. Then it becomes the required sample of precursor-converted ceramics (PolymerDerived Ceramics-PDCs) through high-temperature pyrolysis and porcelain. The process is more of a chemical change. Commonly used ceramic precursors mainly include polysiloxane (Polysiloxane), polycarbosilane (polycarbosilane), and polycarbosilane (polysiloxane) containing silicon atoms in the main chain, which are transformed into SiOC, SiCN, and SiCN by high-temperature pyrolysis after molding—ceramics such as SiC.

Advantages: This method has fast forming speed, a high degree of automation, can create arbitrary complex shapes, high dimensional accuracy, and excellent surface quality. This technology can prepare nano-sized ceramic parts and rapid prototyping complex, high-precision delicate workpieces.

Disadvantages: parts are easy to bend and deform and need support. Parts cured by liquid resins are brittle and prone to breakage. In addition, photosensitive resin and ultraviolet light sources are required to be used in product molding. Still, the photosensitive resin may contain toxic organic substances, which may easily cause environmental pollution during subsequent processing, so it must be protected from light.

SLS Ceramic 3D Printing

It is to replace the binder with a laser beam and use the laser beam to scan the surface of the powder point by point along the path designed by the computer, of bonding. After the laser scanning powder bonding of the previous layer is completed, the powder of the new layer is added, and the three-dimensional structure of the new layer is formed again after laser scanning. In this way, three-dimensional parts with different regional structures can finally be obtained after repeated layer-by-layer laser scanning, high-temperature melting, and local bonding operations according to the abovementioned.

Advantages: It can directly prepare plastic, metal, or ceramics without support, has a wide range of material choices, and has high molding precision. It can manufacture complex components, does not need to increase base support, and has high material utilization.

Disadvantages: Due to the introduction of the laser during the molding process, the powder needs to be preheated and cooled, so the molding cycle is longer, and the subsequent processing process is more complicated.

At the same time, because the raw material powder used needs to be bonded under the action of laser and ultimately fired at high temperature, the types of products that this technology can prepare are limited.

ink jet printing,IJP Ceramic 3D Printing

This technology is developed based on the principle of inkjet printers combined with the concept of 3D printing.

The process is as follows: first, ceramic powder is mixed with various additives and organic substances to make ceramic slurry, also known as “ceramic ink”, and then the slurry is gradually sprayed onto the carrier according to computer instructions by an inkjet printer, so that A ceramic green body with the original design shape and size is formed. There are two key points in this technology: one is the quality of ceramic ink, which not only requires high powder content, but also has strict requirements on dispersion, anti-sedimentation, viscosity, and drying rate; To print the control code, and then use the program to drive the printer action.

Advantages: The forming mechanism is relatively simple, and the cost of the printing head is relatively low. If the ceramic ink problem is solved, this technology’s industrialization can be realized.

Disadvantages: Inkjet printing also has certain limitations. For example, because the size of ink droplets limits the maximum height of printed dots, it is difficult for this technology to prepare three-dimensional components with different heights in the Z-axis direction, and it is also impossible to prepare A ceramic product with an internally porous structure.

Three-dimensional printing, 3DP Ceramic 3D Printing

This technology was initially proposed by the staff of the Massachusetts Institute of Technology based on the principle of “layer-by-layer printing, layer-by-layer superposition”. It is a new technology developed for the development of high-performance ceramics in recent years. The process of applying this technology to the molding of ceramic materials is as follows: first, divide the designed three-dimensional structure of the product into multiple discrete structural units, and then selectively spray the binder onto the surface of the ceramic powder under the control of computer instructions , the final shaped three-dimensional member can be obtained after the powder is bonded.

Application: Currently, 3DP technology has been applied in bioceramics and functional ceramics. For example, high-precision Al2O3-ZrO2 functional stepped ceramic materials and high-strength human plaster bones have been successfully prepared by using this technology.

In Summary

FDM ceramic printing is more suitable for handicrafts, although its surface effect is relatively rough, but the price is low. SLA ceramic printing is more suitable for precision requirements and medical implant parts. SLS ceramic printing is not yet very mature, mainly because the fast laser heating and cooling rate, the residual stress caused by the internal temperature gradient of ceramic parts is still the main factor leading to defects such as cracks and deformation. Although powder bed preheating helps alleviate these issues, the high melting point of ceramics places greater demands on the manufacturing process. Surface roughness, excess porosity, and large shrinkage of ceramic prints also limit their range of applications.

English

English Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano 日本語

日本語 Русский

Русский 中文

中文